When it comes to 3D printing, many users focus on complex designs or advanced materials, but overlook a core factor that determines print success: the first layer. A well-executed first layer lays the groundwork for a flawless final part, while a faulty one often leads to wasted time, material, and failed prints. This article breaks down the importance of the first layer and actionable steps to master it.

1. The Unreplaceable Role of the First Layer in 3D Printing

The first layer is not just the “starting point” of a print—it is the foundation, precision benchmark, and surface quality predictor for the entire object. Below is a detailed breakdown of its three core roles:

| Role | Key Impact | Real-World Example |

| Basic Support | Ensures adhesion between subsequent layers; prevents delamination, warping, or structural collapse. | When printing a multi-layer building model: A poorly printed first layer causes loose connections between upper and lower walls. Even a slight external force (e.g., a light tap) will make the entire model collapse. |

| Precision & Size Benchmark | Determines final dimensional accuracy—deviations here accumulate and amplify with more layers. | When printing a precision mechanical part (e.g., a gear): If the first layer is 0.1mm larger than the design value, after 100 layers, the final part will exceed the tolerance range (±0.05mm) and fail to fit with other components. |

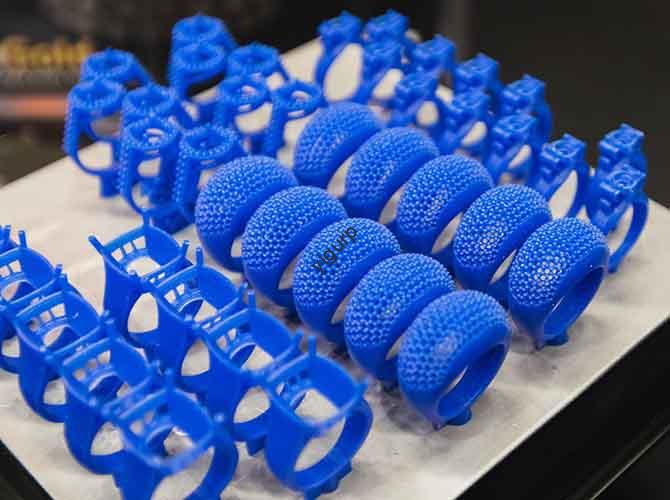

| Surface Quality Driver | Directly affects the final object’s appearance; defects like bubbles or cracks are retained or enlarged in later layers. | When printing high-end jewelry or handicrafts: A tiny bubble (1mm in diameter) on the first layer will expand to a 3mm flaw on the final surface, making the product unmarketable. |

2. 3 Key Steps to Print a Perfect First Layer

Achieving a high-quality first layer is not random—it relies on systematic calibration, material handling, and parameter optimization. Follow this linear workflow to avoid common mistakes:

Step 1: Calibrate the Print Platform (Non-Negotiable!)

Platform calibration ensures the first layer adheres evenly and avoids uneven thickness. Focus on three critical checks:

- Platform Flatness Adjustment

- Use a spirit level to test if the platform is horizontal. If not:

- For manual platforms: Twist the adjustment knobs under the platform until the level bubble is centered.

- For auto-leveling platforms: Run the printer’s “auto-leveling” function (e.g., BLTouch) to correct minor unevenness.

- Nozzle-to-Platform Distance Calibration

This distance (usually 0.1–0.3mm, depending on material) is a make-or-break factor:

- Too large: Material cannot adhere to the platform (the first layer will “float” or peel off).

- Too small: The nozzle scrapes the platform, damaging both the nozzle and the print surface.

- Quick test: Place a piece of printer paper between the nozzle and platform. You should feel slight resistance when pulling the paper—this means the distance is ideal.

- Z-Axis Calibration

The Z-axis controls vertical movement of the nozzle. Inaccurate Z-axis positioning causes uneven first-layer thickness (e.g., some areas are 0.2mm thick, others 0.4mm).

- Solution: Use the printer’s “Z-offset” function to fine-tune—start with a small adjustment (±0.05mm) and test until the first layer is uniform.

Step 2: Select and Prep Materials for Optimal Adhesion

Even perfect calibration fails if the material is mismatched or poorly prepped. Follow these rules:

| Material Type | Compatibility Tips | Pretreatment Steps |

| Filament (e.g., PLA, ABS) | – PLA works with most platforms (glass, PEI); ABS requires a heated bed (60–100°C) for adhesion. – Avoid using filaments with incompatible melting points (e.g., a 190°C PLA in a nozzle set to 250°C). | – Dry filaments in a filament dryer (PLA: 40–50°C for 2 hours; ABS: 80–90°C for 4 hours) to remove moisture (moisture causes bubbles). – Check for tangles—unwind the filament spool slightly before loading to prevent jams. |

| Powder (e.g., SLS Nylon) | – Only use powders recommended by the printer manufacturer (e.g., EOS PA 2200 for EOS SLS printers). | – Sieve the powder with a 100-mesh screen to remove clumps (clumps cause uneven sintering). – Dry the powder at 80°C for 8 hours to eliminate humidity. |

Step 3: Optimize Print Parameters for the First Layer

Default parameters rarely work for all materials—tweak these three settings to match your setup:

| Parameter | How to Optimize | Reasoning |

| Print Temperature | – PLA: 190–210°C – ABS: 230–250°C – PETG: 220–240°C | Too high = material overflows (causes “blobs”); Too low = material doesn’t melt (won’t adhere). |

| Print Speed | Set to 50–70% of the normal speed (e.g., 20–30mm/s instead of 40mm/s). | Slower speed gives the material more time to adhere to the platform and fill gaps evenly. |

| Layer Thickness | – For precision parts: 0.15–0.2mm (improves surface smoothness). – For functional parts (e.g., brackets): 0.2–0.3mm (balances speed and adhesion). | Too thin = increases print time and risk of layer separation; Too thick = causes uneven surfaces. |

3. Yigu Technology’s Perspective on First-Layer Mastery

At Yigu Technology, we believe the first layer is the “litmus test” of 3D printing reliability. Through working with industrial clients (e.g., automotive, medical), we’ve found that 80% of print failures stem from inadequate first-layer preparation. To solve this, we integrate auto-leveling sensors (e.g., 3-point leveling) and material preheating systems into our printers—reducing manual calibration time by 50% while improving first-layer success rates to 95%. For users, mastering the first layer isn’t just about fixing errors; it’s about unlocking the full potential of 3D printing to create consistent, high-quality parts.

FAQ: Common First-Layer Questions Answered

- Q: My first layer keeps peeling off the platform—what should I do?

A: First, check the nozzle-to-platform distance (it may be too large). If that’s correct, increase the bed temperature (e.g., add 5–10°C for PLA) or use an adhesive (e.g., hairspray or 3D printing tape) on the platform.

- Q: Why is my first layer uneven (some areas are thick, others thin)?

A: This is usually a Z-axis calibration issue. Run the printer’s Z-offset adjustment or manually level the platform again. Also, check if the nozzle is clogged (a clogged nozzle reduces material flow in some areas).

- Q: Can I skip first-layer calibration if I use the same material every time?

A: No. Even with the same material, factors like room temperature (affects material flow) or platform wear (changes flatness) can disrupt the first layer. We recommend rechecking calibration every 5–10 prints.