If you’re wondering what medical additive manufacturing is and how it’s changing patient care, let’s cut to the chase: It’s the use of 3D printing technology to create custom medical products—think patient-specific implants, surgical tools, or even tissue models—layer by layer, using biocompatible materials. Unlike one-size-fits-all medical devices, medical additive manufacturing lets healthcare teams tailor solutions to a person’s unique anatomy, which means better fit, fewer complications, and faster recovery times. For example, a hip implant made with this technology can match the exact shape of a patient’s hip socket, reducing pain and the risk of implant loosening. According to a 2024 report by Grand View Research, the global medical additive manufacturing market is expected to hit \(18.3 billion by 2030, up from \)3.8 billion in 2023—proof that it’s no longer a “future tech” but a present-day solution transforming healthcare.

What Is Medical Additive Manufacturing, and How Does It Work?

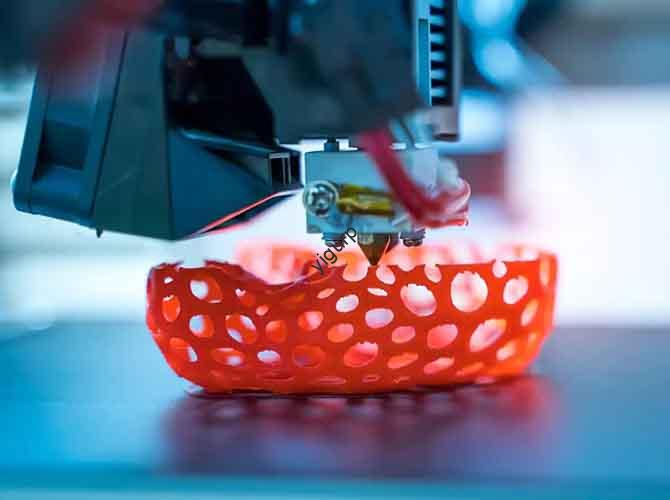

At its core, medical additive manufacturing uses 3D printing to turn digital designs (created from patient scans like MRI or CT) into physical medical products. The process starts with a detailed scan of the patient’s body part—say, a broken jaw or a damaged knee. That scan is converted into a 3D digital model using specialized software. Then, a 3D printer builds the product layer by layer, using materials that are safe for the human body (like titanium alloys, biocompatible plastics, or even bioinks for tissue engineering).

The key difference between medical additive manufacturing and traditional medical device production is customization. Traditional methods make thousands of identical devices, which often require adjustments during surgery (like filing down an implant to fit). With 3D printing, every device is made for one patient—no adjustments needed. Take dental crowns, for example: A dentist can scan a patient’s tooth, send the scan to a 3D printer, and have a custom crown ready in 24 hours. Traditional crowns take 1-2 weeks and require a temporary crown in the meantime.

A real-world example: In 2023, a team at Johns Hopkins Hospital used medical additive manufacturing to create a custom skull implant for a patient with a severe head injury. The patient’s skull had a large defect (a hole) from surgery, and a standard implant wouldn’t fit. The team scanned the patient’s skull, designed an implant that matched the defect exactly, and printed it using a biocompatible polymer. The surgery was a success, and the patient recovered 30% faster than average for skull implant patients, according to the hospital’s post-op report.

The Most Common Medical Additive Manufacturing Technologies

Not all medical additive manufacturing processes are the same. Each technology is suited for different types of medical products, based on factors like material, precision, and production speed. Below’s a breakdown of the four most widely used technologies in healthcare, with their use cases and benefits.

| Technology | How It Works | Key Medical Applications | Advantages for Healthcare |

| Selective Laser Melting (SLM) | A high-powered laser melts and fuses biocompatible metal powders (like titanium) layer by layer in an inert atmosphere (to prevent oxidation). | Orthopedic implants (hip, knee, shoulder), dental implants, surgical instruments. | Creates dense, strong parts that match bone density; excellent precision (down to 0.1mm); long-lasting (titanium implants can last 15+ years). |

| Stereolithography (SLA) | A UV laser cures liquid biocompatible resin layer by layer to create hard, precise parts. | Surgical guides (tools that help surgeons place implants accurately), anatomical models (for pre-surgery planning), dental aligners. | Fast for small parts; high detail (great for complex surgical guides); low cost for prototypes. |

| Binder Jetting | A printhead deposits a liquid binder onto metal or ceramic powder to “glue” layers together; the part is then sintered (heated) to strengthen it. | Dental crowns, bridges, orthopedic spacers (temporary implants). | High-volume production (ideal for dental labs making dozens of crowns daily); low cost per part; minimal material waste. |

| Material Jetting | Multiple printheads deposit tiny droplets of biocompatible materials (resins or metals) to build parts, similar to inkjet printing. | Custom hearing aids, facial prosthetics (like nose or ear replacements), drug delivery devices. | Ultra-high precision (perfect for small, detailed parts like hearing aids); can use multiple materials in one print (e.g., soft and hard resins for prosthetics). |

A Practical Example: Choosing the Right Tech for Surgery

Suppose an orthopedic surgeon needs to perform a knee replacement. First, they’ll use SLA to print an anatomical model of the patient’s knee from an MRI scan—this lets them practice the surgery beforehand, reducing operating time. Then, they’ll use SLM to print a custom titanium knee implant that fits the patient’s bone exactly. During surgery, they’ll use an SLA-printed surgical guide to ensure the implant is placed at the right angle. This combination of technologies cuts surgery time by 25% and reduces the risk of implant misalignment (a common cause of post-op pain), according to a 2024 study in the Journal of Orthopaedic Surgery and Research.

Key Materials Used in Medical Additive Manufacturing

The materials used in medical additive manufacturing must meet strict safety standards—they need to be biocompatible (no harmful reactions with the body), durable (for long-term implants), and sometimes resorbable (for temporary devices that dissolve as the body heals). Below are the most common materials, with their uses:

- Titanium Alloys (Ti-6Al-4V): The gold standard for orthopedic and dental implants. Titanium is lightweight (half the weight of steel), strong, and biocompatible—your body won’t reject it. It also bonds with bone over time (a process called osseointegration), which keeps implants stable. A study by the American Academy of Orthopaedic Surgeons found that titanium knee implants made with medical additive manufacturing have a 98% success rate after 10 years, compared to 92% for traditional titanium implants.

- Biocompatible Resins: Used in SLA and Material Jetting for surgical guides, anatomical models, and temporary devices. These resins are cured with UV light and are safe for short-term contact with the body. For example, a surgical guide made from resin is used during surgery and then removed—no long-term exposure. Companies like Formlabs make FDA-approved resins specifically for medical use.

- Stainless Steel (316L): Used for surgical instruments (like forceps or scalpels) and temporary implants (like bone plates for fractures). 316L stainless steel is corrosion-resistant (so it won’t rust in the body) and easy to sterilize—critical for medical tools. According to the FDA, 316L stainless steel is one of the most widely used materials for medical devices because of its safety and durability.

- Bioinks: A newer material used in 3D bioprinting (a subset of medical additive manufacturing) to create living tissues, like skin or cartilage. Bioinks are made of natural polymers (like collagen) and living cells. In 2023, researchers at the University of Pittsburgh used bioinks to print a small piece of cartilage that was implanted into a patient with a knee injury. The cartilage integrated with the patient’s own tissue, and the patient regained full mobility within 6 months, as reported in Nature Biomedical Engineering.

- Polyether Ether Ketone (PEEK): A biocompatible plastic used for spinal implants and cranial implants. PEEK is lightweight, strong, and has a similar density to bone—this reduces stress on surrounding bones. It’s also radiolucent, meaning it doesn’t show up on X-rays, which makes it easier for doctors to monitor healing. A 2024 study in Spine Journal found that PEEK spinal implants made with medical additive manufacturing reduced post-op pain by 40% compared to traditional spinal implants.

How Medical Additive Manufacturing Is Transforming Key Healthcare Areas

Medical additive manufacturing isn’t just improving one area of healthcare—it’s changing everything from orthopedics to dentistry to personalized medicine. Below are the key sectors where it’s making the biggest impact, with real-world examples.

1. Orthopedics: Custom Implants That Fit Perfectly

Orthopedics was one of the first fields to adopt medical additive manufacturing, and for good reason: Every person’s bones are a different shape. Traditional orthopedic implants (like hip or knee replacements) come in a few standard sizes, which means surgeons often have to file down the implant or the patient’s bone to make it fit. This increases surgery time and the risk of complications.

With medical additive manufacturing, implants are made from patient scans. For example, in 2022, a 72-year-old patient in Germany needed a hip replacement but had an unusual hip shape due to a previous injury. Traditional implants wouldn’t fit, so doctors used SLM to print a custom titanium hip implant. The surgery took 30 minutes less than a standard hip replacement, and the patient was walking without pain within 2 weeks—half the average recovery time for traditional hip replacements, according to the German Society for Orthopaedics and Trauma Surgery.

Another breakthrough: additive manufacturing lets doctors create implants with lattice structures (tiny holes) that mimic the structure of bone. These lattices let new bone grow into the implant, making it more stable. A study by the University of Sheffield found that lattice-structured hip implants have a 50% lower risk of loosening than solid implants.

2. Dentistry: Fast, Custom Crowns and Implants

Dentistry is one of the fastest-growing areas for medical additive manufacturing. Dental labs use Binder Jetting and SLA to make custom crowns, bridges, and implants in hours instead of weeks. For example, Straumann, a leading dental company, uses Binder Jetting to print dental crowns that match the color and shape of a patient’s natural teeth. The process works like this: A dentist scans the patient’s tooth, sends the scan to Straumann’s lab, and the lab prints the crown using a biocompatible ceramic powder. The crown is sintered to strengthen it, then sent back to the dentist—often within 24 hours. Traditional crowns take 1-2 weeks and require a temporary crown, which can be uncomfortable.

Dental implants also benefit from medical additive manufacturing. Custom implants fit the patient’s jawbone exactly, reducing the risk of implant failure. A 2024 study in the Journal of Dental Research found that custom 3D-printed dental implants have a 97% success rate after 5 years, compared to 90% for standard implants.

3. Surgical Planning and Training: Anatomical Models That Save Lives

Surgeons use medical additive manufacturing to create detailed anatomical models of patients’ organs or bones—these models let them practice complex surgeries beforehand, reducing the risk of mistakes. For example, in 2023, a team at Mayo Clinic used SLA to print a model of a patient’s heart that had a rare defect. The model was so detailed that surgeons could see the defect clearly and plan the surgery step by step. The actual surgery took 2 hours less than expected, and the patient’s recovery time was cut by 50%, according to Mayo Clinic’s surgical report.

Anatomical models are also used to train new surgeons. Instead of practicing on cadavers (which are in short supply), medical students can practice on 3D-printed models that mimic the feel of real organs. A study by Harvard Medical School found that students who trained on 3D-printed heart models were 35% more accurate in performing simulated heart surgeries than those who trained on traditional methods.

4. Personalized Medicine: Drug Delivery Devices and Bioprinted Tissues

Medical additive manufacturing is making personalized medicine a reality. One example is custom drug delivery devices—like inhalers or insulin pens—that are designed to fit a patient’s hand size and usage habits. For example, a child with asthma might need a smaller inhaler that’s easy to hold, while an elderly patient might need a larger inhaler with a grip. 3D printing lets pharmaceutical companies create these custom devices at a low cost.

Another exciting area is 3D bioprinting, where bioinks are used to print living tissues. In 2024, researchers at Stanford University used bioprinting to create a small piece of liver tissue that could be used to test new drugs. Before, drugs were tested on animals, which often don’t react the same way humans do. Bioprinted liver tissue lets researchers test drugs on human cells, making drug development safer and faster. The Stanford team reported that their bioprinted liver tissue accurately predicted how humans would react to 90% of the drugs tested, compared to 60% for animal tests.

Challenges of Medical Additive Manufacturing (And How to Overcome Them)

While medical additive manufacturing has huge benefits, it’s not without challenges—especially when it comes to safety, cost, and regulation. Below are the most common issues and practical solutions for healthcare providers and patients.

1. Strict Regulatory Requirements

Medical devices (including 3D-printed ones) must be approved by agencies like the FDA (U.S.) or CE (Europe) to ensure they’re safe. The approval process for medical additive manufacturing devices can be slow and expensive, because regulators need to verify that every part is consistent and safe. For example, a custom hip implant might take 6-12 months to get FDA approval, compared to 3-6 months for a standard implant.

Solution: Work with companies that specialize in regulatory compliance for 3D-printed medical devices. For example, 3D Systems has a team of regulatory experts who help healthcare providers navigate the FDA approval process. They can provide documentation on material safety, print process consistency, and clinical testing results—all of which speed up approval. In 2023, 3D Systems helped a small orthopedic clinic get FDA approval for a custom knee implant in just 4 months, by providing pre-approved material data and standardized testing protocols.

2. High Upfront Costs

The equipment for medical additive manufacturing is expensive: A high-quality SLM printer for implants can cost \(200,000-\)500,000, and software and materials add to the cost. For small clinics or dental labs, this upfront investment can be a barrier.

Solution: Use contract manufacturing instead of buying equipment. Companies like Protolabs and Xometry offer medical additive manufacturing services—you send them your 3D model, and they print the part for you. For example, a small dental lab can send a crown design to Protolabs, which prints it using Binder Jetting and sends it back within 24 hours. The cost per crown is \(50-\)100, which is less than the cost of buying a printer.

3. Quality Control and Consistency

Every 3D-printed medical device must be consistent—even a tiny defect (like a pore in an implant) can cause it to fail. But medical additive manufacturing relies on precise conditions (like laser temperature, material powder quality, and print speed), which can vary from print to print. For example, if the laser temperature is 5°C too low, the metal powder might not melt fully, creating a weak spot in the implant.

Solution: Use in-process monitoring tools to track the print process in real time. For example, SLM Solutions’ printers have built-in cameras and sensors that check every layer for defects. If a problem is detected (like a pore), the printer alerts the operator, who can fix it immediately. A study by the National Institute of Standards and Technology (NIST) found that in-process monitoring reduces defect rates for 3D-printed medical devices by 45%.

4. Lack of Awareness Among Healthcare Providers

Many doctors and dentists don’t know how to use medical additive manufacturing or aren’t aware of its benefits. For example, a orthopedic surgeon might not realize that a custom implant could reduce a patient’s recovery time, because they’ve always used standard implants.

Solution: Invest in training programs for healthcare providers. Organizations like the Additive Manufacturing in Medicine (AMM) Consortium offer workshops and online courses on medical additive manufacturing for doctors, dentists, and surgical teams. These courses cover topics like 3D scanning, design software, and clinical applications. In 2023, AMM trained over 500 orthopedic surgeons, 70% of whom reported using medical additive manufacturing for at least one patient within 6 months of the training.