If you’ve ever noticed subtle diagonal streaks on your 3D printed parts, you’re not alone. These marks—known as 3D printing twill—are a common challenge, but they’re far from unbeatable. This guide breaks down what causes twill, how to fix it, and how different industries adapt to it, so you can achieve smoother, higher-quality prints.

What Exactly Is 3D Printing Twill?

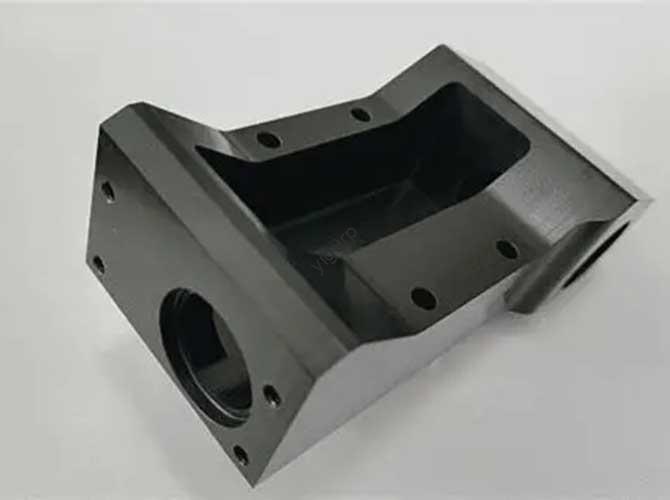

3D printing twill refers to the oblique (diagonal) streaks that appear on the surface of 3D printed objects. Unlike intentional textures, twill is usually an unintended result of process variables, equipment settings, or material properties. It can range from faint lines barely visible to the naked eye to bold streaks that ruin a part’s appearance or functionality.

Think of it like a knit sweater: a well-tuned 3D print is smooth, like a plain knit, while twill is like a lopsided stitch that disrupts the pattern. The good news? Just as you can adjust knitting tension, you can tweak 3D printing settings to reduce or eliminate twill.

Key Factors That Cause 3D Printing Twill

Twill doesn’t happen by accident—it’s triggered by a mix of hardware, software, and material-related issues. Below is a detailed breakdown of the most common causes, organized by category:

| Factor Category | Specific Issues | How They Cause Twill |

| Hardware | – Printhead diameter mismatch- Unstable optical axis- Loose extruder parts | A mismatched printhead may deposit inconsistent filament; a wobbly optical axis or loose extruder causes uneven movement, leading to diagonal streaks. |

| Software/Slicing | – Too fast/too slow print speed- Excessive layer thickness- Over/under-extrusion | Speed extremes disrupt filament flow; thick layers reduce layer bonding (creating visible gaps); incorrect extrusion leads to uneven material deposition. |

| Model & Export | – Poor model file quality- Incorrect export settings (e.g., wrong STL resolution) | Low-quality models or bad exports create irregularities in the print path, which show up as twill. |

| Materials & Printer Type | – High-shrinkage materials (e.g., ABS)- FDM vs. SLA printers | Materials that shrink unevenly pull layers out of alignment; FDM printers (which use filament) are more prone to twill than SLA (resin-based) printers, due to mechanical movement. |

Step-by-Step Solutions to Fix 3D Printing Twill

Fixing twill starts with identifying the root cause, but these actionable steps work for most scenarios. Follow this 递进 (progressive) process to troubleshoot:

- Optimize Slicing Parameters First

Slicing settings are the easiest to adjust and often the main culprit. Focus on:

- Speed: Test speeds 10-20% slower/faster than your default (e.g., drop from 60mm/s to 50mm/s for PLA).

- Layer Thickness: Reduce to 0.15-0.2mm (thicker layers = more visible twill).

- Extrusion Rate: Calibrate to 95-105% (use a calibration cube to check for gaps or blobs).

- Check and Tune Your Hardware

- Tighten loose optical axis screws (wobble here causes diagonal movement).

- Ensure your printhead diameter matches your slicer settings (e.g., a 0.4mm nozzle needs a 0.4mm setting).

- Clean the extruder gear (debris can cause uneven filament feeding).

- Adjust Model Placement & Post-Processing

- Rotate the model on the build plate to avoid supports on the main appearance surface (supports leave marks that look like twill).

- Use post-processing: Sand the surface with 200-400 grit sandpaper, then apply a coat of primer or paint to hide remaining streaks.

- Choose the Right Printer & Material

- For high-precision parts, switch to an SLA printer (resin prints have smoother surfaces than FDM).

- Pick low-shrinkage materials (e.g., PLA instead of ABS) to reduce layer misalignment.

How Different Industries Handle 3D Printing Twill

Twill’s impact varies by industry—what’s acceptable for a prototype may be a dealbreaker for aerospace parts. Here’s a 对比 (comparison) of key use cases:

| Industry | Attitude Toward Twill | Actions Taken |

| Prototyping | Acceptable (function > appearance) | No post-processing needed for functional tests; light sanding for client presentations. |

| Art & Design | Often intentional (texture = style) | Designers adjust settings to enhance twill, using it to add depth to sculptures or jewelry. |

| Aerospace & Medical | Zero tolerance (twill = weak points) | Use SLA or high-end FDM printers; perform 100% inspection; add precision post-processing (e.g., CNC machining). |

| Consumer Goods | Low tolerance (appearance matters) | Calibrate for minimal twill; use post-processing (painting, vapor smoothing for ABS) to achieve a polished look. |

Yigu Technology’s Perspective on 3D Printing Twill

At Yigu Technology, we see 3D printing twill not as a flaw, but as a feedback signal—it tells you when your process needs refinement. Our engineers recommend starting with parameter calibration (our free slicing software preset for FDM printers cuts twill by 60% for PLA) and upgrading to precision hardware (like our dual-axis optical system) for consistent results. For industrial clients, we combine SLA printing with custom post-processing to meet strict surface standards. Twill is solvable, and with the right tools, it never has to compromise your prints.

FAQ: Common Questions About 3D Printing Twill

- Q: Can I completely eliminate twill from FDM prints?

A: It’s hard to eliminate 100%, but you can reduce it to near-invisibility with calibration, slow speeds (40-50mm/s), and post-processing (sanding + painting).

- Q: Is twill a sign that my 3D printer is broken?

A: Rarely. Most twill comes from settings, not hardware failure. Start with slicer tweaks before replacing parts.

- Q: Does resin (SLA) printing ever cause twill?

A: SLA prints can have faint lines from layer curing, but these are usually vertical (not diagonal like FDM twill). You can fix them with light sanding or resin polishing.