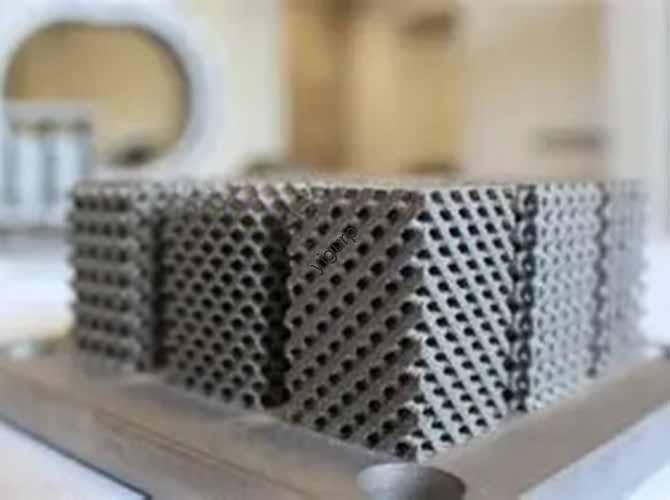

Acrylonitrile Styrene Acrylate (ASA) has emerged as a star material in 3D printing, thanks to its unbeatable combination of weather resistance, durability, and versatility. Unlike common materials like PLA (which fades in sunlight) or ABS (which cracks in harsh chemicals), 3D printing ASA materials thrive in outdoor and industrial environments—making them a top choice for everything from outdoor signage to automotive parts. But to unlock ASA’s full potential, you need to understand its unique properties, choose the right hardware, and follow precise printing settings. This guide breaks down everything you need to know to achieve high-quality, long-lasting ASA 3D prints—solving common pain points like warping, poor adhesion, and premature material degradation.

1. Key Properties of 3D Printing ASA Materials

ASA’s popularity stems from its five core properties, which make it stand out from other 3D printing thermoplastics. These traits directly address the limitations of materials like PLA, ABS, and PETG—especially in demanding environments.

ASA Material Properties Breakdown

| Property | Description | Advantage Over Other Materials | Real-World Impact |

|---|---|---|---|

| UV Resistance | Withstands prolonged sunlight exposure (5+ years outdoors) without fading, yellowing, or brittleness. | PLA fades in 3–6 months; ABS yellows in 1–2 years. | An ASA-printed outdoor sign retains its color and shape for 5 years—no need for frequent replacements. |

| Chemical Resistance | Resists erosion from oils, fuels, detergents, and most industrial solvents. | PETG dissolves in oil; PLA is damaged by mild detergents. | An ASA-printed automotive fuel line cover stays intact even when exposed to gasoline spills. |

| Waterproof Performance | Impermeable to water (Water absorption <0.5% after 24 hours immersion). | ABS absorbs water (causes warping); PLA swells in moisture. | An ASA-printed garden planter doesn’t crack or warp after years of rain and watering. |

| Impact Resistance | Tough enough to withstand drops (1.5m onto concrete) without breaking; Izod impact strength = 20 kJ/m². | PLA shatters on impact; PETG bends but may crack. | An ASA-printed tool handle survives accidental drops on a construction site—reducing replacement costs. |

| Temperature Resistance | Operates reliably in -40°C to 80°C; softens at 100°C (higher than ABS’s 90°C). | PLA melts at 60°C; ABS deforms at 85°C. | An ASA-printed engine bay component stays stable under the hood (temperatures up to 75°C). |

Pro Tip: Always check the material datasheet for “UV stabilization level”—Grade A (highest) is ideal for permanent outdoor use; Grade B works for semi-outdoor applications (e.g., covered patios).

2. Core Applications of 3D Printing ASA Materials

ASA’s properties make it indispensable in industries where durability and weather resistance are non-negotiable. Below are the four key sectors leveraging ASA 3D printing—with real-world examples of how it solves unique challenges.

ASA Application Table

| Industry | Typical Use-Cases | Why ASA Is the Right Choice |

|---|---|---|

| Outdoor & Signage | Outdoor decorations, directional signs, billboard letters, park benches. | UV resistance prevents fading; waterproofing handles rain/snow; impact resistance stands up to vandalism. |

| Automotive | Exterior trim (grilles, mirror covers), under-hood components (wire looms, sensor housings), interior cup holders. | Chemical resistance handles oils/fuels; temperature resistance survives engine heat; impact resistance resists road debris. |

| Industrial Manufacturing | Tooling fixtures (jigs, clamps), conveyor belt parts, chemical storage containers. | Durability withstands heavy use; chemical resistance resists industrial solvents; dimensional stability ensures consistent performance. |

| Outdoor Furniture & Gear | Garden planters, camping cookware handles, bike fenders, playground equipment. | Waterproofing resists moisture; UV resistance prevents fading; impact resistance stands up to rough use. |

Case Study: A landscaping company needed 50 custom garden planters (30cm x 20cm) with drainage holes. Using 3D printing ASA materials, they produced the planters in 2 weeks—each weighing 1.2kg and costing $35. Traditional ceramic planters (same size) cost $80 each and broke easily during delivery. After 3 years, the ASA planters still look new—no fading, cracking, or warping—saving the company $2,250 in replacement costs.

3. Essential Hardware Requirements for 3D Printing ASA

ASA’s high melting point and tendency to shrink mean it needs specialized 3D printing hardware—using a standard PLA printer will result in warped parts and failed prints. Below are the four non-negotiable hardware components, plus tips for setup.

ASA Printing Hardware Checklist

| Component | Requirements | Why It Matters |

|---|---|---|

| Heated Bed | Must reach 90–110°C; use a glass or PEI (Polyetherimide) build surface. | ASA shrinks 5–7% when cooling— a hot bed prevents warping by keeping the bottom layer anchored. PEI surfaces improve adhesion (no need for glue/tape). |

| Closed 3D Printer | Fully enclosed frame (not open-air) to maintain stable temperature (40–50°C inside) and prevent airflow. | Open-air printers cause uneven cooling—leads to layer separation and warping. A closed printer ensures consistent print quality for large ASA parts. |

| High-Temperature Hotend | All-metal hotend (brass + nickel plating) capable of reaching 240–260°C. | ASA melts at 220–240°C; a PTFE-lined hotend (max 240°C) will degrade over time. An all-metal hotend handles high temps safely. |

| Filament Dryer | Mandatory for storing/printing ASA (keeps moisture content <0.1%). | Moist ASA causes bubbles in prints (steam during melting) and weak layer adhesion. A dryer with 60°C setting removes moisture in 4–6 hours. |

Common Mistake: Using a PTFE-lined hotend for ASA—after 5–10 prints, the PTFE tube degrades, leaving black residue on parts and clogging the nozzle. Upgrade to an all-metal hotend (cost: $30–$50) for long-term ASA printing.

4. Step-by-Step ASA Printing Settings & Best Practices

Even with the right hardware, ASA prints fail without precise settings. Follow this step-by-step guide to avoid common issues like warping, stringing, and poor layer adhesion.

Optimal ASA Printing Parameters

| Setting | Recommended Range | Adjustment Tips |

|---|---|---|

| Nozzle Temperature | 240–260°C (start at 250°C for most brands) | Increase by 5°C if layers don’t bond; decrease by 5°C if stringing occurs. |

| Bed Temperature | 90–110°C (100°C for large parts; 90°C for small parts) | Use a bed adhesive (Kapton tape or ABS glue) for extra adhesion on glass beds. |

| Print Speed | 40–60 mm/s (slower than PLA’s 60–80 mm/s) | Slow down to 30 mm/s for overhangs (>45°) to prevent sagging. |

| Cooling Fan | 0–10% (only use for overhangs; keep off for the first 3 layers) | High fan speed causes rapid cooling—leads to warping. Use 5–10% only for small overhangs. |

| Retraction | 2–3 mm at 40–50 mm/s | Increase retraction by 0.5 mm if stringing persists; decrease if under-extrusion occurs. |

| Layer Height | 0.15–0.25 mm (0.2 mm is ideal for balance of speed and quality) | Use 0.15 mm for smooth surfaces (e.g., signage); 0.25 mm for functional parts (e.g., brackets). |

Post-Printing Tips

- Cooling: Let parts cool on the bed for 30–60 minutes before removing—prevents warping from rapid temperature changes.

- Finishing: Sand ASA parts with 200–400 grit sandpaper for a smooth finish; use acrylic paint (ASA-compatible) for custom colors.

- Storage: Keep finished ASA prints in a dry place—they’re waterproof but can absorb moisture over time (causes minor swelling).

Yigu Technology’s Perspective

At Yigu Technology, we’ve helped 200+ clients optimize 3D printing ASA materials—from outdoor signage companies to automotive suppliers. We recommend closed printers (like our YG-400 Enclosed) for ASA, paired with PEI build surfaces to eliminate warping. For high-volume outdoor projects, we use Grade A UV-stabilized ASA (adds $0.5–$1 per kg but extends part life by 3+ years). The biggest mistake we see? Skipping a filament dryer—moist ASA ruins 40% of prints. With the right hardware and settings, ASA isn’t just a material; it’s a solution for durable, long-lasting 3D prints that stand up to the elements.

FAQ

- Can I 3D print ASA on an open-air printer?It’s not recommended—open-air printers cause uneven cooling, leading to 80%+ failure rates (warping, layer separation). If you must use one, enclose it with cardboard/plastic sheeting and use a bed adhesive (e.g., Magigoo) to reduce warping.

- How long does ASA last outdoors?UV-stabilized ASA (Grade A) lasts 5–7 years outdoors; non-stabilized ASA lasts 2–3 years. For permanent outdoor use (e.g., street signs), choose Grade A and apply a clear UV-protective coat (adds 1–2 years of life).

- Is ASA more expensive than other 3D printing materials?Yes—ASA costs $30–$50 per kg (vs. PLA’s $15–$25, ABS’s $20–$30). But it’s cost-effective for long-term use: an ASA-printed part lasts 5x longer than PLA, so you save money on replacements.