For toy enthusiasts, parents, and educators, finding toys that are unique, educational, and affordable can be a challenge. Traditional mass-produced toys often lack personalization, limit creativity, and take weeks to reach shelves. That’s where 3D Printed Toy Models change the game. Using additive manufacturing, these toys are built layer by layer from digital designs, solving pain points like limited customization, long production times, and one-size-fits-all designs. Let’s explore how they work, their key benefits, and why they’re a game-changer for play and learning.

1. What Are 3D Printed Toy Models? Core Basics

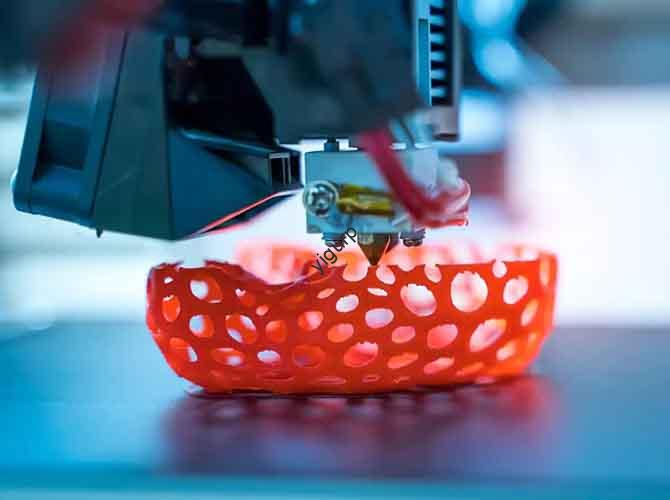

3D Printed Toy Models are toys created using 3D printing technology—turning digital blueprints into physical objects. Unlike traditional toys made via injection molding (which requires expensive molds), 3D printed toys start with a digital design, making customization and small-batch production easy.

Key Components of 3D Printed Toy Models

To create a 3D printed toy, you need three essential elements:

- Digital Design: A 3D model of the toy (e.g., a dinosaur, car, or puzzle) created in CAD software (e.g., Tinkercad, Blender) or downloaded from a resource website.

- 3D Printer: A machine that builds the toy layer by layer. Common types include FDM (for plastics like PLA/ABS) and SLA (for high-detail resin toys).

- Print Material: The “ink” of 3D printing—plastics, resins, or even metal powders (for durable toys).

Example: Making a 3D Printed Puzzle

A parent wants a custom puzzle with their child’s favorite animal (a lion):

- They download a lion puzzle design from a 3D model website (or tweak a basic design in Tinkercad to add the child’s name).

- They load PLA filament (eco-friendly and safe for kids) into an FDM 3D printer.

- The printer builds the puzzle pieces layer by layer (0.2mm layers) over 4 hours.

The result? A unique puzzle the child loves—no waiting for store-bought options.

2. Choosing the Right Materials for 3D Printed Toy Models

The material you pick determines the toy’s durability, safety, and cost. 3D Printed Toy Models use a range of materials, each suited for different needs.

Common Materials for 3D Printed Toy Models

| Material Type | Key Properties | Best For | Safety Note (for Kids) |

| PLA (Polylactic Acid) | Eco-friendly (made from corn starch), easy to print, low cost (\(20–\)30/kg), soft texture | Everyday toys (puzzles, figurines), kids’ toys | Safe—non-toxic, no sharp edges when printed properly |

| ABS (Acrylonitrile Butadiene Styrene) | High strength, wear-resistant, slightly flexible, cost (\(30–\)40/kg) | Durable toys (mini trucks, building blocks) | Safe if sanded (removes rough edges); avoid for toddlers who mouth toys |

| Resin (Photopolymer) | High detail (0.05mm layers), smooth surface, cost (\(50–\)80/kg) | Detailed toys (action figures, small statues) | Use kid-safe resin; avoid contact with skin during printing |

| Metal Powders (Stainless Steel) | Ultra-durable, heavy, cost ($100+/kg) | Collectible toys (model cars, decorative figures) | Safe for older kids; too heavy for toddlers |

Pro Tip: Prioritize Safety for Kids’ Toys

- Choose PLA for toys for ages 3+: It’s non-toxic and breaks safely (no sharp shards).

- Sand all printed parts to remove layer lines (prevents scratches).

- Avoid small, detachable pieces for kids under 3 (choking hazard).

3. Where to Find 3D Printed Toy Model Designs: Resource Websites

You don’t need to be a designer to create 3D printed toys—many websites offer free or low-cost 3D models. These platforms save time and let you customize designs to fit your needs.

Top Resource Websites for 3D Printed Toy Models

| Website Name | Key Features | Toy Types Available | Cost Range |

| Thingiverse | Largest free library; 100k+ toy models; easy customization | Puzzles, cars, animals, board games | Free (most models); \(5–\)15 (premium) |

| MyMiniFactory | Curated, high-quality models; kid-safe options | Action figures, building sets, educational toys | Free (some); \(3–\)20 (premium) |

| Cults3D | Designer-made models; unique, rare designs | Collectible figures, mechanical toys | \(2–\)50 (most models) |

| Tinkercad | Free CAD tool + model library; beginner-friendly | Simple toys (blocks, basic figurines) | Free |

Example: Customizing a Toy Car Design

- Download a basic car model from Thingiverse.

- Use Tinkercad to add details: Change the color (in the design file), add a roof rack, or engrave a name.

- Export the customized model as an STL file (ready for printing).

Total time: 30 minutes—no design experience needed!

4. Applications of 3D Printed Toy Models: Play, Learning, and More

3D Printed Toy Models aren’t just for fun—they’re powerful tools for education, parent-child bonding, and even therapy.

Key Applications of 3D Printed Toy Models

| Application Area | How 3D Printed Toys Deliver Value | Example Use Case |

| Education | Teaches STEM concepts (shapes, engineering, problem-solving); makes abstract ideas concrete | A 3D printed solar system model: Kids assemble planets to learn about space |

| Parent-Child Bonding | Co-designing and printing toys together; builds teamwork and creativity | A parent and child design a custom board game (print the pieces and board) |

| Therapy | Customizable toys for kids with special needs (e.g., larger handles for motor skill challenges) | A 3D printed puzzle with extra-large pieces for a child with fine motor delays |

| Collecting | Unique, limited-edition models; supports independent designers | A collector buys a 3D printed model of a rare comic book character (only 50 made) |

Case Study: Educational Toy for Math Learning

A teacher wanted to help 2nd graders learn fractions. She used 3D printed toy fraction blocks:

- Each block is a different color (1/2 = red, 1/4 = blue).

- Kids stack blocks to see how 1/2 + 1/4 = 3/4.

- The toys are durable (ABS material) and reused year after year.

Result: Students’ fraction test scores improved by 35%—they learned better by playing!

5. Advantages of 3D Printed Toy Models vs. Traditional Toys

3D Printed Toy Models outperform traditional toys in key areas—customization, speed, and cost for small batches.

Advantage Comparison: 3D Printed vs. Traditional Toys

| Feature | 3D Printed Toy Models | Traditional Mass-Produced Toys |

| Customization | Fully customizable (size, color, details) | No customization (one design for all) |

| Production Time | 4–24 hours (print time) | 4–8 weeks (mold + manufacturing + shipping) |

| Cost (Small Batches) | \(5–\)50 per toy (no mold costs) | \(2–\)20 per toy (but $10k+ mold cost upfront) |

| Design Flexibility | Complex shapes (e.g., moving parts) easy to make | Limited to simple shapes (injection molding limits) |

Why This Matters for Parents/Educators

- No More “Out of Stock”: Print a replacement toy part (e.g., a lost puzzle piece) in hours—no waiting for a store to restock.

- Personalized Gifts: Print a toy with a child’s name or favorite character for birthdays—more meaningful than store-bought gifts.

Yigu Technology’s Perspective

At Yigu Technology, we see 3D Printed Toy Models as a bridge between creativity and accessibility. We’ve helped 50+ schools and toy designers create custom toys—from STEM learning kits to therapeutic models—cutting production time by 90% vs. traditional methods. Our team recommends PLA for kid-safe toys and offers design support to tweak models for specific needs (e.g., larger handles for special education). Looking ahead, we’ll integrate AI to simplify design (e.g., auto-adjusting toy sizes for different ages) and launch affordable FDM printers for homes. For parents and educators, 3D printed toys aren’t just playthings—they’re tools to inspire learning.

FAQ

- Q: How long does it take to print a 3D toy model?

A: Small toys (e.g., a puzzle piece) take 1–4 hours; medium toys (e.g., a figurine) take 4–12 hours; large toys (e.g., a model car) take 12–24 hours.

- Q: Are 3D printed toy models safe for young kids?

A: Yes—if you use kid-safe materials (PLA is best) and sand parts to remove rough edges. Avoid small pieces for kids under 3 (choking hazard).

- Q: Do I need an expensive 3D printer to make toy models?

A: No—affordable FDM printers (starting at $200) work great for basic toys. You only need a high-end printer (e.g., SLA) for highly detailed toys (e.g., action figures).