If you’re a product designer or manufacturer looking to create accurate 3D printing handboards for new product development, one of the first questions you’ll ask is: “What materials should I use?” Choosing the right material directly affects your handboard’s durability, appearance, and whether it matches your final product’s performance. Let’s break down the most common 3D printing handboard materials, their uses, and how to pick the best one for your project.

Common 3D Printing Handboard Materials & Their Key Details

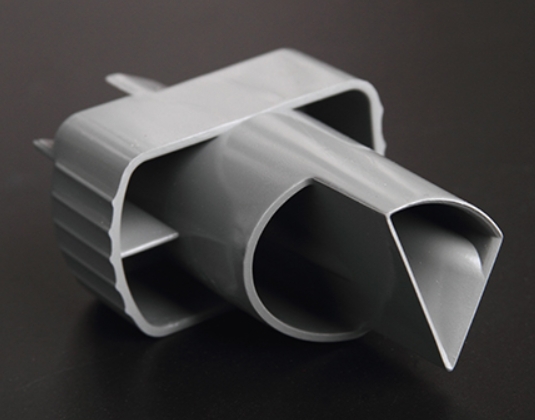

To make it easy for you to compare, we’ve organized the top materials into a clear table. Each entry includes the material name, suitable 3D printing technology, main advantages, and typical handboard applications.

| Material Type | Suitable 3D Printing Technology | Key Advantages | Typical Handboard Applications | Average Cost (Per kg) |

| Engineering Plastics (ABS/PLA) | FDM (Fused Deposition Modeling) | Low cost, easy to print, good impact resistance (ABS) | Consumer product prototypes (toys, household goods), structural test parts | \(20 – \)50 |

| Photopolymer Resins | SLA (Stereolithography)/DLP (Digital Light Processing) | High detail, smooth surface finish, high precision | High-precision prototypes (electronic casings, jewelry models), visual display handboards | \(80 – \)150 |

| Rubber-Like Materials | FDM/SLS (Selective Laser Sintering) | Flexible, elastic, good grip | Handboards for soft parts (grips, gaskets, shoe soles) | \(60 – \)120 |

| Metal Materials (Titanium Alloy/Stainless Steel) | SLM (Selective Laser Melting)/SLS | High strength, corrosion resistance, heat resistance | Industrial part prototypes (automotive components, aerospace parts), functional test handboards | \(300 – \)800 |

| Ceramic Materials | SLA/SLS | High temperature resistance, high precision, aesthetic appeal | Artistic handboards, dental implant models, high-temperature test parts | \(150 – \)300 |

| Composite Materials (Carbon Fiber-Reinforced Plastic) | FDM/SLS | Lightweight, high strength, rigid | High-performance handboards (drone frames, sports equipment prototypes) | \(100 – \)250 |

| Food Materials (Sugar/Chocolate) | Specialized Food 3D Printers | Edible, customizable shapes | Promotional handboards (food product samples, decorative cake toppers) | \(50 – \)100 |

| Gypsum Materials (Colored) | Binder Jetting | Vibrant colors, easy to shape, low cost | Visual display handboards (sculptures, architectural models) | \(30 – \)80 |

| Artificial Bone Powder | SLS/SLM | Biocompatible, matches bone structure | Medical handboards (orthopedic implant prototypes, surgical guides) | \(500 – \)1,200 |

How to Choose the Right Material for Your 3D Printing Handboard

Picking a material isn’t just about cost—it needs to fit your handboard’s purpose. Here are 4 key factors to consider, with simple questions to guide your decision:

1. What’s the Handboard’s Main Use?

- If it’s for visual display (e.g., showing a product’s design to clients), go for photopolymer resins (smooth surface) or colored gypsum (vibrant colors).

- If it’s for functional testing (e.g., checking if a part can withstand pressure), choose engineering plastics (ABS) or metal materials (high strength).

- If it’s for medical or biocompatible needs (e.g., orthopedic prototypes), artificial bone powder is the top choice.

2. What’s Your Budget?

- Budget-friendly options (under $50/kg): PLA (a type of engineering plastic) and gypsum. Great for simple visual handboards.

- Mid-range options (\(50 – \)200/kg): ABS, rubber-like materials, and composite materials. Balanced for most testing and display needs.

- High-end options (over $200/kg): Metals (titanium alloy) and artificial bone powder. For industrial or medical-grade handboards.

3. Do You Need Special Properties?

- Flexibility: Rubber-like materials are the only choice for handboards that need to bend (e.g., a prototype of a phone case with a soft edge).

- Heat Resistance: Ceramic materials or stainless steel work best if your handboard will be exposed to high temperatures (e.g., a prototype of a kitchen appliance part).

- Lightweight & Strength: Composite materials like carbon fiber-reinforced plastic are perfect for handboards that need to be strong but not heavy (e.g., a drone frame prototype).

Yigu Technology’s View on 3D Printing Handboard Materials

At Yigu Technology, we believe that the right 3D printing handboard material is the bridge between design ideas and market-ready products. Based on our work with hundreds of manufacturing clients, engineering plastics (ABS/PLA) and photopolymer resins are the most versatile choices for most new product 研发 (R&D) projects—they balance cost, ease of printing, and performance. For industrial clients needing high-strength handboards, we recommend carbon fiber composites or stainless steel, as they replicate the durability of final parts. We also see growing demand for biocompatible materials like artificial bone powder in medical R&D, and we’re committed to offering these options to support innovative healthcare solutions.

FAQ

Q1: Can I use PLA for functional test handboards?

PLA is great for visual handboards, but it’s less durable than ABS. For light functional tests (e.g., checking fit), it works. But for tests involving impact or heat, ABS or metal is better.

Q2: Are rubber-like materials suitable for long-term handboard use?

Rubber-like materials can degrade slightly over time (especially if exposed to sunlight), so they’re best for short-term handboards (e.g., 1-3 months of testing). For longer use, consider adding a protective coating.

Q3: How much does a metal 3D printing handboard cost compared to a plastic one?

On average, a metal handboard costs 5-10 times more than a plastic one. For example, a small plastic handboard (100g) might cost \(5-\)10, while a similar metal handboard could cost \(50-\)100. The exact price depends on the metal type (titanium is more expensive than stainless steel) and handboard size.