When working with metal—whether for construction, automotive projects, or DIY crafts—understanding the thickness of 16 gauge metal is critical. The gauge system follows an inverse rule: higher gauge numbers mean thinner materials. However, 16 gauge thickness isn’t universal; it varies by metal type due to differences in material properties, manufacturing processes, and industry standards. This article breaks down the exact thickness of 16 gauge metal for common materials, explains why variations exist, and highlights key considerations for practical use.

1. Core Data: 16 Gauge Thickness by Metal Type

The most critical information for any project is the exact thickness measurement of 16 gauge metal. Below is a comprehensive table comparing thickness (in both inches and millimeters) for four widely used metals, along with their key properties and typical applications.

| Metal Type | Thickness (Inches) | Thickness (Millimeters) | Key Material Properties | Primary Applications |

| Standard Steel | ~0.0598” | 1.519 mm | High strength, durability | Structural frames, load-bearing beams |

| Galvanized Steel | ~0.0603” | 1.613 mm | Corrosion-resistant (zinc-coated) | Outdoor roofing, fencing, HVAC ducts |

| Stainless Steel | ~0.059” | 1.588 mm | Rust-proof, chemical resistance | Food processing equipment, medical tools |

| Aluminum | ~0.062” | 1.57 mm | Lightweight, high strength-to-weight ratio | Aerospace parts, automotive panels, DIY decor |

Key Observations from the Table:

- Galvanized Steel is the thickest of the four (0.0603”), thanks to its zinc coating, which adds a thin protective layer.

- Standard Steel is the thinnest among steel variants (0.0598”), but still offers superior strength for structural tasks.

- Aluminum has a slightly thicker profile than stainless steel (0.062” vs. 0.059”) but is significantly lighter—making it ideal for weight-sensitive projects.

2. Why Does 16 Gauge Thickness Vary by Metal?

You might wonder: If 16 gauge is a “standard,” why do thicknesses differ? The answer lies in material-specific properties and manufacturing goals. Here’s a breakdown of the key reasons, using side-by-side comparisons for clarity:

2.1 Material Density and Strength

Metals have varying densities, which affect how manufacturers roll and shape them to meet 16 gauge specifications. For example:

- Steel (dense, strong): To achieve the required strength for 16 gauge applications (e.g., structural support), manufacturers roll steel to a thinner profile (0.0598”). A thicker steel sheet would be overengineered and unnecessarily heavy.

- Aluminum (less dense, lighter): Aluminum is naturally weaker than steel, so manufacturers make 16 gauge aluminum slightly thicker (0.062”) to compensate. This thicker profile ensures it still meets strength requirements for its use cases (e.g., automotive panels) without adding excess weight.

2.2 Coating and Surface Treatments

Some metals require coatings to enhance performance, which adds to their overall thickness. The best example is galvanized steel:

- Galvanized steel starts as standard steel but is dipped in molten zinc to create a corrosion-resistant layer. This zinc coating adds ~0.0005” to the thickness, increasing it from 0.0598” (standard steel) to 0.0603”.

- Without this coating, 16 gauge galvanized steel would match standard steel’s thickness—but it would lack the rust resistance needed for outdoor use.

2.3 Industry Standards

Different industries set unique standards for 16 gauge thickness to align with their needs:

- The construction industry prioritizes consistency in standard steel (0.0598”) to ensure structural safety across buildings.

- The food processing industry requires stainless steel (0.059”) to be thin enough for easy cleaning but thick enough to resist dents and chemical damage.

3. Practical Implications: Choosing the Right 16 Gauge Metal

Understanding thickness variations isn’t just academic—it directly impacts project success. Below is a step-by-step guide to selecting the right 16 gauge metal, paired with real-world scenarios.

Step 1: Define Your Project’s Core Needs

Start by asking three questions:

- Will the metal be exposed to moisture (e.g., outdoor fencing)?

- Is weight a concern (e.g., aerospace parts)?

- Does it need to bear heavy loads (e.g., structural beams)?

Step 2: Match Needs to Metal Properties

Use the checklist below to align your project with the right 16 gauge metal:

| Project Requirement | Best 16 Gauge Metal Choice | Reasoning |

| Outdoor/High-Moisture Use | Galvanized Steel | Zinc coating prevents rust; 0.0603” thickness ensures durability. |

| Lightweight but Strong | Aluminum | 0.062” thickness balances strength and weight; ideal for portable projects. |

| Corrosion-Resistant (Indoor) | Stainless Steel | 0.059” thickness resists chemicals and rust (e.g., kitchen equipment). |

| Heavy Load-Bearing | Standard Steel | 0.0598” thickness offers maximum strength for structural tasks. |

Real-World Scenario Example:

If you’re building a DIY outdoor garden bed, 16 gauge galvanized steel is the best choice. Its 0.0603” thickness is strong enough to hold soil and plants, while the zinc coating prevents rust from rain and moisture. Choosing aluminum (0.062”) would be too weak for heavy soil, and standard steel would rust quickly—leading to a short-lived project.

4. How to Accurately Measure 16 Gauge Metal Thickness

Even with standard specifications, it’s critical to verify thickness before starting a project (manufacturing tolerances can cause small variations). Below are the best tools and techniques for accurate measurement:

4.1 Top Tools for Measuring 16 Gauge Metal

| Tool Type | Best For | Accuracy Range | How to Use |

| Micrometer | Thin metals (e.g., aluminum) | ±0.0001” | Place the metal between the anvil and spindle; rotate the thimble for a tight fit. |

| Digital Calipers | All metals | ±0.001” | Clamp the jaws around the metal; read the digital display for thickness. |

| Thickness Gauge | Sheet metals (e.g., steel) | ±0.0005” | Use the flat probe to press against the metal; read the dial. |

4.2 Tips to Avoid Measurement Errors

- Calibrate Tools First: Micrometers and calipers need regular calibration (every 6 months) to ensure accuracy.

- Measure Multiple Points: Metal sheets can have slight thickness variations—take 3–5 measurements across the surface and average them.

- Account for Coatings: If measuring galvanized steel, the 0.0603” thickness includes the zinc coating—don’t subtract it (the coating is part of the metal’s functional thickness).

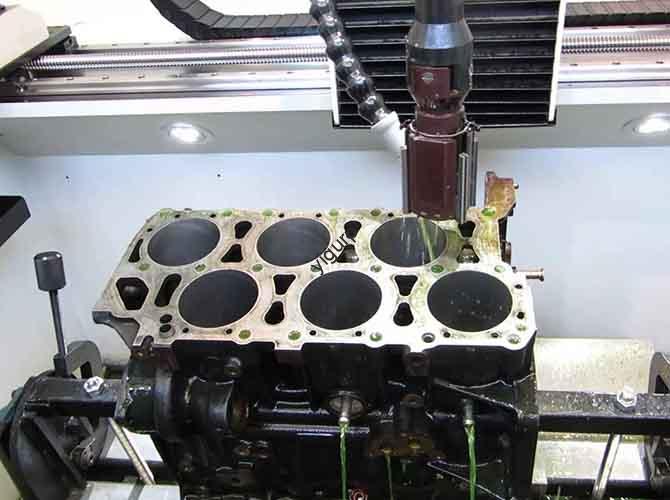

5. Yigu Technology’s Perspective on 16 Gauge Metal

At Yigu Technology, we work closely with manufacturers and DIY enthusiasts to provide metal solutions that align with project goals. From our experience, 16 gauge metal is one of the most versatile options for balancing strength, workability, and cost—but its success depends on choosing the right material for the job.

We often see clients make avoidable mistakes, such as using standard steel for outdoor projects (leading to rust) or aluminum for load-bearing tasks (leading to structural failure). Our recommendation: Always prioritize material properties over thickness alone. For example, 16 gauge galvanized steel’s 0.0603” thickness isn’t just a number—it’s a combination of strength and corrosion resistance that solves specific outdoor challenges.

For industrial clients, we also emphasize the importance of verifying thickness with calibrated tools. Even a 0.001” variation in 16 gauge stainless steel can affect the performance of medical equipment or food processing machines—so precision matters.

FAQ

Q1: Is 16 gauge metal thicker than 18 gauge metal?

Yes. The gauge system follows an inverse relationship: higher gauge numbers mean thinner metal. For example, 16 gauge standard steel is 0.0598” thick, while 18 gauge standard steel is ~0.0478” thick—making 16 gauge 25% thicker.

Q2: Can 16 gauge aluminum be used for outdoor projects?

Yes, but with caveats. 16 gauge aluminum (0.062”) is lightweight and naturally corrosion-resistant (it forms a protective oxide layer). However, it’s less strong than galvanized steel—so it’s best for lightweight outdoor projects (e.g., decorative planters) rather than heavy-duty tasks (e.g., fencing).

Q3: Why is 16 gauge stainless steel thinner than 16 gauge aluminum?

Stainless steel is denser and stronger than aluminum. To achieve the same functional strength for 16 gauge applications, stainless steel only needs a thinner profile (0.059”)—whereas aluminum requires a slightly thicker profile (0.062”) to compensate for its lower density. This ensures both metals meet the performance standards expected of 16 gauge.