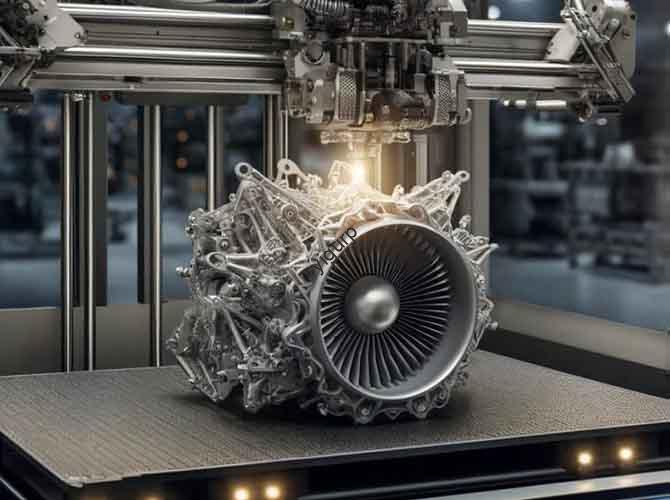

If you’re a small or medium-sized manufacturer (SME) wondering whether metal additive printing is just a fancy buzzword or a tool that can actually boost your product development, you’re not alone. The short answer is: metal additive printing—also known as metal 3D printing—is a game-changing technology that lets you create strong, complex metal parts faster, more affordably, and with less waste than traditional manufacturing methods like forging or milling. Unlike plastic 3D printing (which uses polymers), metal additive printing uses purified metal powders to build parts layer by layer, making it ideal for industrial components that need to withstand high stress, heat, or pressure—think turbine blades, engine parts, or custom machine components.

In this guide, we’ll break down everything you need to know about metal additive printing: how it works, why it’s been out of reach for SMEs until now, how to use it effectively, and what the future holds for the technology. We’ll also include real-world examples and data to help you decide if it’s right for your business.

How Does Metal Additive Printing Work? A Simple Breakdown for Manufacturers

At its core, metal additive printing is about building parts “from the ground up” using metal powder and heat—usually a laser or electron beam. The most common method for industrial use is Laser Powder Bed Fusion (LPBF), which is what many modern machines (including compact models for SMEs) rely on. Here’s a step-by-step breakdown of how LPBF works, in plain language:

- Prepare the Design: First, you create or tweak a 3D digital model of your part using software like Autodesk Netfabb or Fusion 360. This software lets you optimize the design for additive printing—for example, adding support structures to prevent warping or arranging parts to fit more efficiently in the machine.

- Load the Metal Powder: The machine uses metal powder (often stainless steel, titanium, or aluminum) that’s been purified to avoid contamination. Many newer machines package this powder in standardized cartridges (more on this later) for safety and ease of use—no messy manual handling required.

- Layer-by-Layer Printing: The machine spreads a thin layer of metal powder (usually 20–50 microns thick) across a build platform. A high-powered laser (typically 200–400 watts for SME machines) then melts the powder in the exact shape of your part’s first layer.

- Repeat and Build: The build platform lowers slightly, and the machine adds another layer of powder. The laser melts this layer to the one below it, and the process repeats until the part is complete.

- Finish and Recycle: Once printing is done, you remove the part and clean off any unused powder. Many machines include tools to recycle unused powder (like ultrasonic sieves) so you can reuse it for future prints—cutting down on waste and cost.

What makes this different from traditional manufacturing? Let’s compare:

| Method | How It Works | Pros | Cons | Best For |

| Metal Additive Printing | Layer-by-layer melting of metal powder | Complex designs, less waste, fast prototyping | Higher upfront cost (for large machines), size limits | Custom parts, prototypes, low-volume production |

| Forging | Heating metal to high temps and shaping with force | Strong parts, high-volume production | Limited complexity, high energy use | Simple, high-strength parts (e.g., bolts) |

| Milling | Cutting metal from a solid block | Precise for simple shapes | Lots of waste, slow for complex designs | Low-complexity parts in medium volumes |

Why Metal Additive Printing Was Out of Reach for SMEs—Until Now

For years, metal additive printing was a “big company” tool. If you’re an SME, you might have thought: “That’s great for NASA or SpaceX, but it’s too expensive, too big, and too complicated for my shop.” You weren’t wrong—until recently. Here are the three biggest barriers that kept SMEs from adopting metal additive printing, and how new innovations are breaking them down:

1. Cost: From “Millions” to “Affordable for SMEs”

Historically, industrial metal 3D printers cost $500,000 or more—way out of budget for most small manufacturers. On top of that, the metal powder and software added to the expense. But today, compact machines designed for SMEs can cost a fraction of that. For example, newer models use vending machine–size frames (instead of room-sized behemoths) and leverage economies of scale from parent companies with laser expertise (like Trumpf, a leader in manufacturing tools). This has brought the price down to a range that’s accessible for businesses looking to prototype or produce small batches of parts.

2. Complexity: From “Needs a Specialist” to “One Click”

Early metal 3D printers required trained technicians to operate—you needed to know how to handle metal powder safely, calibrate the laser, and fix issues like warping. Now, user-friendly machines include features like:

- Pre-packaged powder cartridges: No more manual handling (which reduces contamination risk).

- Cloud-based software integration: Tools like Autodesk Netfabb let you tweak designs without advanced engineering skills.

- Automated post-processing: Some machines (like the MPUREpro model) automatically clean parts and recycle unused powder—so you don’t need extra staff for finishing.

3. Space and Safety: From “Needs a Dedicated Lab” to “Fits Next to Your Milling Machine”

Older metal 3D printers needed large, climate-controlled rooms to prevent powder contamination and ensure safety. Newer compact models are designed to fit in standard manufacturing spaces—even next to your existing machines. They also include safety features like sealed powder systems (to keep moisture and dust out) and built-in ventilation, so you don’t need to invest in special infrastructure.

Real-World Uses: How Manufacturers Are Leveraging Metal Additive Printing

Talk is cheap—let’s look at how actual businesses and organizations are using metal additive printing to solve problems. These examples show the technology’s versatility, from prototyping to full-scale production.

Example 1: SMEs Cutting Production Time with Custom Components

A German manufacturing company (previously an R&D unit of a laser tools giant) faced a challenge: it needed a driver component to open and close its metal powder cartridges. The component had limited space in the machine, and the motor required a “feather key” (a small metal piece) for power transmission. Traditional methods—like pushing, broaching, or milling the keyway—were slow and expensive, especially for small batches.

Using metal additive printing, the company:

- Designed the component in Autodesk Fusion 360, optimizing it for the machine’s build volume.

- Stacked multiple parts in the printer (rotated 180 degrees to reduce support structures) to fit more in one print.

- Printed the components in a fraction of the time it would have taken to mill them—and reused the unused powder.

The result? A 30% reduction in production time and lower costs, with parts that met all the motor’s specifications.

Example 2: NASA and SpaceX: Metal Additive Printing for Space

If you need proof of metal additive printing’s strength, look to the sky. NASA plans to 3D print more than 80% of its future rocket engines using metal additive systems. Why? Rocket engines need complex, lightweight parts that can withstand extreme heat (up to 6,000°F) and pressure—something traditional manufacturing struggles to produce without extra weight or waste.

SpaceX has also invested heavily in metal 3D printing. The company uses it to make parts for its Starship rockets, including engine components. By 3D printing these parts, SpaceX has reduced the number of components in some engines from 1,000+ to just 10—cutting assembly time and improving reliability.

Example 3: Construction: The World’s First 3D-Printed Metal Bridge

In 2021, Imperial College London unveiled the world’s first 3D-printed metallic bridge in Amsterdam. The bridge, made of stainless steel, was printed in sections and assembled on-site. Why is this a big deal? Traditional bridge construction requires casting large metal parts, which are heavy and expensive to transport. 3D printing let engineers create a lighter, stronger bridge with complex designs that distribute weight more evenly—all while using less material.

Key Considerations for SMEs Looking to Adopt Metal Additive Printing

If you’re ready to explore metal additive printing for your business, here are four critical factors to keep in mind. These will help you avoid common mistakes and get the most value from your investment.

1. Choose the Right Machine for Your Needs

Not all metal 3D printers are created equal. For SMEs, focus on machines that check these boxes:

- Size: Look for compact models (vending machine–size or smaller) that fit in your existing space.

- Build Volume: Consider the largest part you’ll need to print. Most SME machines have a build volume of around 150mm x 150mm x 150mm—enough for most prototypes and small components.

- Ease of Use: Prioritize machines with automated features (like cartridge-based powder loading and recycling) and intuitive software. You don’t want to hire a specialist just to operate it.

- Powder Compatibility: Make sure the machine works with the metal powders you’ll use (e.g., stainless steel for durability, aluminum for lightweight parts).

2. Optimize Your Designs for Additive Printing

One of the biggest mistakes new users make is using the same designs they’d use for forging or milling. Metal additive printing lets you create shapes that were impossible before—but you need to optimize your designs for the process. Here are three tips:

- Minimize Support Structures: Supports are necessary to prevent warping, but they add time and material. Rotate parts or use self-supporting angles (usually 45 degrees or more) to reduce supports.

- Stack Parts Efficiently: Use software like Autodesk Netfabb to stack multiple parts in the build volume. This reduces the number of prints you need to run and cuts down on waste.

- Consider Powder Recycling: Design parts that leave as little unused powder as possible, and choose machines that let you recycle that powder (most modern models do this with ultrasonic sieves).

3. Understand the Total Cost of Ownership

The upfront cost of the machine is just one part of the equation. You also need to budget for:

- Metal Powder: Expect to pay \(50–\)200 per kilogram, depending on the type (titanium is more expensive than stainless steel).

- Software: Some machines include basic software, but you may need to upgrade to tools like Autodesk Fusion 360 for advanced design (monthly subscriptions start at around $50).

- Maintenance: Regular cleaning and laser calibration will be needed—factor in time or cost for this.

The good news? Metal additive printing reduces waste (since you only use the powder you need) and cuts down on prototyping time—so the total cost often pays off within a year for SMEs.

4. Prioritize Powder Safety and Quality

Metal powder is the lifeblood of additive printing—but it can be risky if not handled properly. Here’s how to keep your team safe and your parts high-quality:

- Use Sealed Cartridges: Avoid machines that require manual powder handling (which can cause contamination or respiratory issues). Sealed cartridges keep powder clean and safe.

- Store Powder Properly: Keep unused powder in a dry, cool place. Moisture can ruin the powder and lead to faulty parts.

- Recycle Responsibly: Use machines with integrated sieves to recycle unused powder. This not only saves money but also ensures the powder is clean for future use.

The Future of Metal Additive Printing: Market Trends and Opportunities

Metal additive printing isn’t just a passing trend—it’s a growing market with huge potential for SMEs. Here’s what you need to know about the market outlook and upcoming opportunities.

Market Growth: By the Numbers

According to Grand View Research, the global metal 3D printing market was valued at $3.52 billion in 2022—and it’s expected to grow at a 23.9% annual rate between 2022 and 2030. That’s a faster growth rate than most manufacturing technologies. Why? Because more businesses are realizing the benefits of rapid prototyping, custom parts, and reduced waste.

The biggest drivers of growth include:

- Aerospace and Defense: Companies like NASA and SpaceX are increasing their use of metal additive printing for rocket parts.

- Automotive: Car manufacturers are using it to make lightweight, high-strength components (e.g., engine brackets).

- Medical: Metal 3D printing is used to make custom implants (like hip replacements) that fit patients perfectly.

Emerging Opportunities for SMEs

As the market grows, new opportunities are opening up for small manufacturers:

- Custom Parts for Niche Markets: If you serve a niche industry (e.g., agricultural machinery or marine equipment), metal additive printing lets you create custom parts quickly—without the high cost of tooling for traditional manufacturing.

- On-Demand Production: Instead of keeping inventory of spare parts, you can print them on demand. This reduces storage costs and ensures you always have the parts you need.

- Collaboration with Large Companies: Many large manufacturers (like aerospace firms) are looking for SMEs to supply 3D-printed components. Having metal additive printing capabilities can make you a more attractive partner.

Yigu Technology’s Perspective on Metal Additive Printing

At Yigu Technology, we believe metal additive printing is no longer a “luxury” for large corporations—it’s a necessity for SMEs looking to stay competitive in a fast-changing manufacturing landscape. The key advantage of this technology is its ability to level the playing field: SMEs can now create complex, high-quality metal parts that were once only possible for big companies with massive budgets.

We’ve seen firsthand how metal additive printing reduces lead times for prototypes (from weeks to days) and cuts down on waste—two critical pain points for small manufacturers. However, we also advise businesses to take a strategic approach: start with small, high-impact projects (like custom tooling or replacement parts) to test the technology before scaling up. As the market grows and machines become even more affordable, we expect metal additive printing to become a standard tool in SME shops—just like CNC mills or 3D plastic printers are today.

FAQ: Your Top Metal Additive Printing Questions Answered

1. Is metal additive printing as strong as traditionally manufactured metal parts?

Yes—if not stronger. Metal additive printing creates parts with a dense, crystalline microstructure that can withstand industrial stress, heat, and pressure. In fact, some 3D-printed parts (like NASA’s rocket components) are stronger than traditionally made parts because they have fewer seams or weak points.

2. How long does it take to 3D print a metal part?

It depends on the size and complexity of the part. A small prototype (e.g., a 50mm x 50mm x 50mm component) might take 4–8 hours to print. Larger or more complex parts could take 24 hours or more. However, this is still faster than traditional prototyping methods, which can take weeks.

3. Can I use metal additive printing for high-volume production?

Metal additive printing is ideal for low-to-medium volume production (e.g., 10–1,000 parts). For very high volumes (10,000+ parts), traditional methods like forging or injection molding may still be cheaper. However, as machines become faster and more affordable, this gap is closing.

4. What types of metal can I use with additive printing?

The most common metals are stainless steel, aluminum, titanium, and nickel alloys. Each has its own benefits: stainless steel is durable and affordable, aluminum is lightweight, titanium is strong and corrosion-resistant (ideal for medical or aerospace parts), and nickel alloys can withstand high temperatures.

5. Do I need special training to operate a metal 3D printer?

No—most modern machines for SMEs are designed to be user-friendly. Many come with tutorials and intuitive software, so you or your existing staff can learn to operate them in a few days. However, it’s still a good idea to take a short training course (often offered by the machine manufacturer) to learn best practices for design and maintenance.