If you’re running a CNC machine shop, you’ve probably asked: “What are CNC spare parts, and how do I manage them to keep my machines running?” Simply put, CNC spare parts are the replaceable components that keep Computer Numerical Control (CNC) machines operating—from small sensors to large spindle units. Without the right spare parts on hand, even a minor component failure can shut down production for days, costing your business thousands in lost revenue. In this guide, we’ll break down everything you need to know: from identifying critical parts to buying quality components, maintaining inventory, and avoiding common mistakes.

What Are CNC Spare Parts, and Why Do They Matter?

First, let’s clarify: CNC spare parts are not just “extra parts”—they’re a strategic investment in uptime. CNC machines are complex systems with hundreds of moving and electronic components, and over time, wear, vibration, or electrical issues will cause parts to fail. The difference between a 2-hour downtime and a 2-week delay often comes down to whether you have the right spare part in stock.

Consider this real-world example: A mid-sized automotive parts manufacturer in Ohio recently experienced a failure of the ball screw in their 5-axis CNC mill. They didn’t have a spare, so they had to order one from overseas. The lead time was 10 days, and during that period, they lost \(45,000 in contracted work—far more than the \)800 cost of keeping a spare ball screw on the shelf.

Key Role of CNC Spare Parts in Production

- Minimize Downtime: The average CNC machine downtime costs \(500–\)2,000 per hour (source: Manufacturing Technology Insights, 2024). Spare parts cut this time drastically.

- Protect Machine Longevity: Replacing worn parts (like bearings or seals) prevents further damage to expensive components (e.g., spindles or control boards).

- Ensure Quality Output: Faulty parts (such as damaged linear guides) lead to inaccurate cuts, wasting material and ruining finished products.

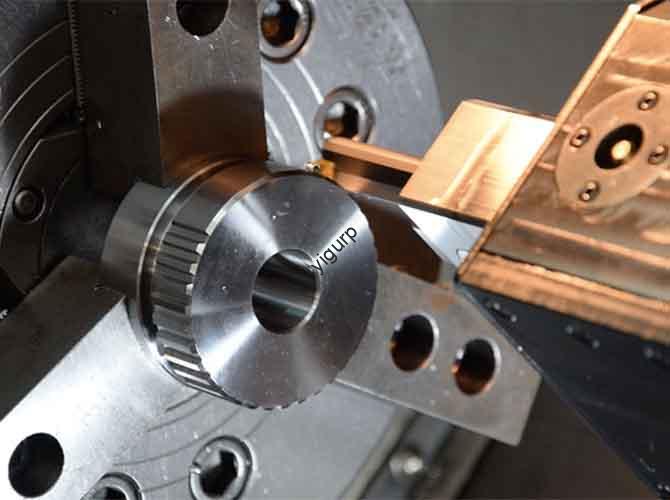

Common Types of CNC Spare Parts (With Examples)

Not all CNC spare parts are the same—some are critical, while others are “nice to have.” Below is a breakdown of the most common categories, with examples of parts you’ll likely need to replace.

| Category | Key Components | Typical Failure Causes | Replacement Frequency |

| Mechanical Parts | Ball screws, linear guides, bearings, spindles, tool holders | Wear from friction, vibration, contamination | 6–24 months (varies) |

| Electrical Parts | Servo motors, control boards, sensors (proximity, temperature), power supplies | Electrical surges, overheating, component aging | 12–36 months |

| Hydraulic/Pneumatic | Hoses, cylinders, valves, filters | Leaks, pressure changes, dirt buildup | 3–12 months |

| Consumables | Cutting tools, coolant filters, lubricants, O-rings | Regular use, material wear, contamination | 1–4 weeks |

Critical vs. Non-Critical Parts

- Critical Parts: These cause immediate downtime if they fail. Examples include servo motors (control machine movement) and spindle units (drive cutting tools). You should always keep 1–2 spares of these.

- Non-Critical Parts: Failures here don’t stop production immediately. Examples include indicator lights or coolant hoses. You can order these with a 1–3 day lead time.

How to Choose the Right CNC Spare Parts (Avoid Costly Mistakes)

Choosing the wrong spare part can damage your CNC machine or lead to repeated failures. Here’s a step-by-step process to make sure you buy the right one—backed by a real 案例 from a shop owner.

Step 1: Gather Exact Machine Details

Never guess! You need three key pieces of information:

- Machine Model & Serial Number: Found on the machine’s nameplate. For example, a Haas VF-2 with serial number H202305.

- Part Number: The manufacturer’s unique code for the part (e.g., Fanuc part number A06B-6117-H105 for a servo motor).

- Application: What does the part do? A spindle for aluminum cutting will have different specs than one for steel.

Case Study: Mike, owner of a small CNC shop in Texas, once ordered a “compatible” linear guide for his Mazak machine without checking the part number. The guide was slightly shorter, causing misalignment. He had to reorder the correct part (costing $300 extra) and spend 8 hours realigning the machine—wasting a full day of production.

Step 2: OEM vs. Aftermarket vs. Refurbished Parts

You have three options when buying spare parts—each with pros and cons.

| Type | Description | Pros | Cons | Best For |

| OEM | Made by the machine’s original manufacturer (e.g., Haas parts for Haas machines) | Perfect fit, warranty, reliable quality | Most expensive (20–50% higher than aftermarket) | Critical parts (spindles, control boards) |

| Aftermarket | Made by third-party companies to match OEM specs | Lower cost (15–30% cheaper), wider availability | Quality varies—some are low-grade | Non-critical parts (bearings, hoses) |

| Refurbished | Used parts that have been repaired/tested to meet OEM standards | Cheapest option (30–60% off OEM) | Shorter lifespan, limited warranty | Backup spares for older machines |

Pro Tip: For safety-related parts (like emergency stop switches) or parts that affect precision (like ball screws), always choose OEM. For generic parts (like standard bearings), aftermarket brands like SKF or Timken are reliable.

Step 3: Check Quality & Warranty

- Quality Checks: Ask for test reports (e.g., for servo motors, check torque and speed ratings). Avoid parts with no brand name or vague specs—these are often counterfeit.

- Warranty: OEM parts usually come with a 12–24 month warranty. Aftermarket parts should have at least 6 months. Refurbished parts may have 3–6 months.

- Red Flag: If a seller offers a “too-good-to-be-true” price (e.g., a \(200 OEM spindle that normally costs \)1,500), it’s likely counterfeit. Counterfeit parts cause 23% of CNC machine failures (source: CNC Machine Tool Association, 2024).

How to Manage Your CNC Spare Parts Inventory (Practical System)

Even if you buy the right parts, poor inventory management means you’ll still struggle when a part fails. Here’s a simple, scalable system used by successful shops.

Step 1: Categorize Your Inventory

Use the “ABC” system to prioritize parts:

- A-Class (Critical): 10% of parts, 70% of downtime risk. Examples: spindle units, servo motors. Keep 1–2 spares in stock.

- B-Class (Important): 30% of parts, 20% of downtime risk. Examples: linear guides, sensors. Keep 1 spare or reorder when stock hits 50%.

- C-Class (Low Priority): 60% of parts, 10% of downtime risk. Examples: O-rings, fuses. Reorder when stock runs low (lead time < 3 days).

Step 2: Use Inventory Management Tools

You don’t need expensive software—start with these:

- Spreadsheets: Track part name, part number, quantity, reorder level, supplier, and cost. Update it weekly.

- Barcode Scanners: For larger shops, tools like Fishbowl or Sortly let you scan parts to update inventory automatically.

- Cloud Tools: Google Sheets or Microsoft Excel Online let your team access inventory from the shop floor or office.

Step 3: Set Reorder Triggers

- For A-Class parts: Reorder when stock is at 1 (since you need 1 spare on hand).

- For B-Class parts: Reorder when stock hits 50% of your average monthly usage.

- For C-Class parts: Reorder when stock is empty (since lead time is short).

Example: If you use 4 coolant filters per month (C-Class), reorder when you run out—you can get new ones in 2 days, so no need to stockpile.

How to Extend the Life of CNC Spare Parts (Maintenance Tips)

Spare parts aren’t just for replacement—you can extend the life of installed parts to reduce how often you need to use spares. Here are three expert tips:

1. Follow a Regular Lubrication Schedule

- Why: Friction is the #1 cause of mechanical part failure (e.g., ball screws, bearings).

- How: Use the lubricant recommended by your machine’s manufacturer (e.g., Mobil Vactra Oil for linear guides). Lubricate every 8–12 hours of machine operation.

- Tool: Set a reminder on your CNC controller or phone to avoid missing lubrication.

2. Keep Parts Clean & Free of Contamination

- Coolant Filters: Replace them every 2–4 weeks to prevent dirt from entering spindle bearings.

- Dust Covers: Use magnetic or rubber dust covers on linear guides to keep out metal chips.

- Example: A shop in Illinois reduced linear guide replacements by 40% just by adding dust covers and changing coolant filters on time (source: Shop Floor Management Report, 2023).

3. Monitor Part Performance

- Sensors: Use vibration sensors (e.g., Fanuc AI Vibration Monitor) to detect early signs of bearing wear.

- Logs: Record when parts are replaced and why. Over time, you’ll spot patterns (e.g., “Our spindle bearings fail every 18 months—we should order a spare at 16 months”).

Yigu Technology’s View on CNC Spare Parts

At Yigu Technology, we believe CNC spare parts are the backbone of reliable manufacturing—not just “extra costs.” Too many shops treat spare parts as an afterthought, only ordering them when a machine breaks. This reactive approach leads to unnecessary downtime and lost revenue. Instead, we recommend a proactive strategy: prioritize critical OEM parts for precision and safety, use high-quality aftermarket parts for non-critical components, and track inventory with simple tools. We’ve worked with shops that cut downtime by 35% just by implementing this system. Additionally, we emphasize regular maintenance—extending the life of installed parts means you’ll use spares less often, saving money in the long run. For small to mid-sized shops, starting with an ABC inventory system and a basic spreadsheet is enough to see results. The goal isn’t to stock every part—it’s to stock the right parts, at the right time, to keep your machines running.

FAQ About CNC Spare Parts

1. How much should I budget for CNC spare parts?

A good rule of thumb is 3–5% of your CNC machine’s total cost per year. For example, if you have a \(100,000 CNC mill, budget \)3,000–$5,000 annually for spare parts.

2. Can I use aftermarket parts for my new CNC machine?

For new machines (under 5 years old), stick to OEM parts for critical components (spindles, control boards) to avoid voiding your machine’s warranty. Aftermarket parts are safe for non-critical components (bearings, hoses).

3. How do I store CNC spare parts properly?

Store parts in a clean, dry area with controlled temperature (50–80°F). For mechanical parts (like ball screws), use anti-rust oil and wrap them in plastic. For electrical parts (like control boards), keep them in anti-static bags.

4. What if I can’t find a spare part for an old CNC machine?

First, check with the original manufacturer—they may have discontinued parts but can recommend compatible alternatives. If that fails, look for refurbished parts from specialized suppliers (e.g., CNC Parts Depot) or consider retrofitting the machine with newer components.

5. How often should I review my spare parts inventory?

Review A-Class parts weekly (to ensure you have spares), B-Class parts monthly, and C-Class parts quarterly. Update your inventory list every time you use or order a part to avoid stockouts.