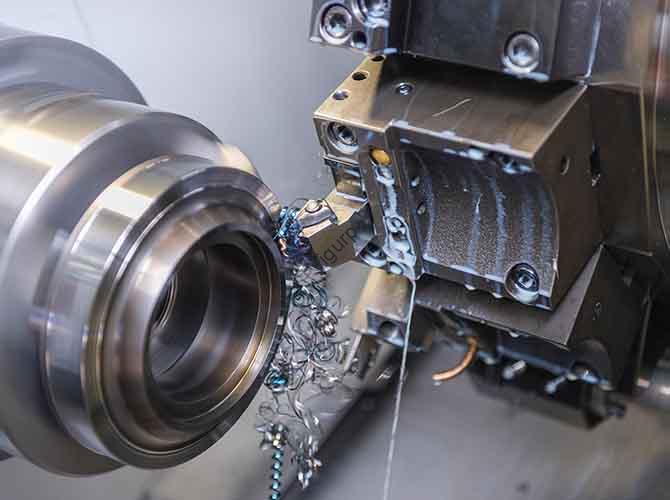

If you’re a motorcycle enthusiast looking to upgrade your bike’s performance, durability, or appearance, you’ve probably heard of CNC motorcycle parts. But what exactly are they, and why are they worth investing in? Simply put, CNC motorcycle parts are components manufactured using Computer Numerical Control (CNC) machining—a precision manufacturing process that uses computer programs to control tools like drills, lathes, and mills. This method ensures each part is made with extreme accuracy, consistency, and quality, making them a popular choice for riders who want more from their motorcycles than stock parts can offer. Whether you’re rebuilding an engine, upgrading your brakes, or customizing your bike’s look, CNC parts deliver benefits that go beyond what traditional manufacturing methods can provide.

What Is CNC Machining and How Does It Make Better Motorcycle Parts?

To understand why CNC motorcycle parts stand out, it’s important to first grasp how CNC machining works. Unlike manual manufacturing, where a worker operates tools by hand, CNC machining uses pre-programmed computer software to guide machine tools. This software follows a digital design (usually a 3D model) of the part, ensuring every cut, drill, and shape is executed with microscopic precision—often within tolerances of just 0.001 inches.

For motorcycle parts, this precision is a game-changer. Let’s take a common component like a CNC motorcycle brake caliper as an example. A brake caliper needs to fit perfectly with the brake pads, rotor, and hydraulic lines to function safely and effectively. With CNC machining, the caliper’s mounting holes, piston chambers, and sealing surfaces are all created to exact specifications. This means no loose fits, no leaks, and consistent braking performance every time you squeeze the lever. In contrast, a manually made caliper might have slight variations that lead to uneven brake wear, reduced stopping power, or even safety risks.

Another key advantage of CNC machining for motorcycle parts is consistency. If you need two identical parts—say, CNC handlebar clamps for a custom build—CNC machines can produce hundreds (or thousands) of copies that are identical in every way. This is crucial for parts that need to work together, like engine components or suspension parts, where even small differences can cause vibration, noise, or premature failure.

Key Benefits of Upgrading to CNC Motorcycle Parts

Switching to CNC motorcycle parts isn’t just about “upgrading for the sake of upgrading”—it’s about solving real problems riders face with stock or low-quality components. Here are the most impactful benefits you’ll notice:

1. Superior Durability for Long-Term Use

CNC parts are often made from high-grade materials like aluminum alloy, stainless steel, or titanium—materials that are stronger and more resistant to wear than the plastic or low-grade metal used in many stock parts. For example, a CNC motorcycle sprocket (which transfers power from the engine to the rear wheel) is typically machined from hardened aluminum or steel. Unlike a stock plastic sprocket, a CNC metal sprocket can handle the stress of constant acceleration and deceleration without cracking or wearing down quickly.

A real-world example: A friend of mine who rides off-road replaced his stock plastic chain guide with a CNC aluminum one. Before the upgrade, he had to replace the plastic guide every 2-3 months because it would break or wear down from dirt and rocks. After switching to the CNC part, he’s had the same guide for over a year—saving him time and money on replacements.

2. Improved Performance That You Can Feel

Precision manufacturing directly translates to better performance. Let’s look at CNC motorcycle carburetor jets—small components that control the amount of fuel mixed with air in the engine. Stock jets are often mass-produced with looser tolerances, which can lead to an uneven fuel-air mixture. This might cause your bike to idle roughly, hesitate when accelerating, or use more fuel than necessary.

CNC-machined jets, on the other hand, have exact hole sizes and smooth internal surfaces. This ensures a consistent fuel flow, leading to smoother idling, faster acceleration, and better fuel efficiency. A study by a leading motorcycle parts manufacturer found that riders who upgraded to CNC carburetor jets saw a 5-8% improvement in fuel economy and a 10% increase in low-end torque—changes that are noticeable every time you ride.

3. Customization Options for a Unique Bike

One of the biggest draws of CNC parts is their ability to be customized. Unlike stock parts, which are designed to fit a wide range of bikes (and often lack personality), CNC parts can be tailored to your specific style and needs. Whether you want CNC motorcycle footpegs with a unique grip pattern, a CNC fuel cap with your favorite logo, or even custom CNC engine covers in a bold color, CNC machining makes it possible.

Many manufacturers offer custom CNC parts services, where you can work with a designer to create a 3D model of your ideal part. For instance, a rider who owns a vintage Honda CB750 might want to update the bike’s look with a CNC-machined headlight bracket that matches the bike’s classic lines but adds a modern touch. CNC machining allows for this level of detail without sacrificing functionality.

4. Reduced Maintenance and Repair Costs

While CNC parts might have a higher upfront cost than stock or cheap aftermarket parts, they save you money in the long run by reducing maintenance and repair needs. Let’s take CNC motorcycle wheel spacers—small parts that keep the wheel aligned with the frame. Stock spacers are often made from soft metal, which can wear down over time from vibration. When spacers wear out, the wheel can become misaligned, leading to uneven tire wear, poor handling, and even damage to the frame or axle.

A CNC-machined wheel spacer, made from high-strength aluminum, is far more resistant to wear. It will last longer, meaning you won’t have to replace it as often. Additionally, the precise fit of CNC spacers reduces the risk of misalignment, which prevents costly repairs to other components like tires or axles. Over time, these savings can easily offset the initial cost of the CNC part.

Common Types of CNC Motorcycle Parts (And What They Do)

CNC machining is used to make a wide range of motorcycle parts, from small components to major engine parts. Here’s a breakdown of the most popular types, what they do, and why you might want to upgrade them:

| Part Type | Function | Key Benefit of CNC Version |

| Brake Calipers | Squeeze brake pads against the rotor to slow/stop the bike | Precision fit reduces leaks; better heat dissipation for consistent braking |

| Handlebar Clamps | Secure the handlebars to the fork tube | Tighter grip prevents handlebar movement; customizable designs for comfort |

| Sprockets | Transfer power from the engine to the rear wheel via the chain | Harder material resists wear; precise tooth shape reduces chain stretch |

| Carburetor Jets | Control fuel flow into the engine’s combustion chamber | Consistent fuel-air mixture for smoother performance and better fuel economy |

| Footpegs | Provide a stable platform for the rider’s feet | Custom grip patterns reduce slippage; durable material withstands impacts |

| Engine Covers | Protect internal engine components from dirt, debris, and damage | Stronger than stock plastic; can be customized for style without blocking heat dissipation |

| Wheel Spacers | Keep the wheel aligned with the frame and axle | Precise fit prevents misalignment; high-strength material resists wear and vibration |

| Clutch Levers | Activate the clutch to change gears | Lightweight design reduces hand fatigue; adjustable reach for different hand sizes |

How to Choose the Right CNC Motorcycle Parts for Your Bike

With so many CNC parts available, it can be overwhelming to know which ones are right for your motorcycle. Follow these steps to make an informed decision:

Step 1: Identify Your Goals (Performance, Style, or Durability)

First, figure out what you want to improve about your bike. Are you looking to make it faster? More durable for off-roading? Or do you want to give it a custom look? Your goals will narrow down your options. For example:

- If performance is your top priority: Focus on parts like CNC carburetor jets, CNC brake calipers, or CNC clutch levers.

- If durability is key (e.g., for off-roading): Look for CNC aluminum skid plates, CNC chain guides, or CNC wheel spacers.

- If style is important: Consider CNC fuel caps, CNC handlebar ends, or CNC engine covers in custom colors.

Step 2: Check Compatibility with Your Bike’s Make and Model

Not all CNC parts fit every bike. Even if a part looks like it will work, small differences in frame size, engine type, or mounting points can cause fitment issues. Always check the manufacturer’s compatibility list before buying. For example, a CNC brake caliper designed for a Yamaha YZF-R6 won’t fit a Harley-Davidson Sportster—they have different brake systems and mounting points.

If you’re unsure, reach out to the manufacturer or a trusted motorcycle mechanic. They can help you confirm if a part will work with your bike.

Step 3: Look for Quality Materials and Certifications

The quality of the material used in a CNC part directly affects its performance and durability. Most high-quality CNC motorcycle parts are made from:

- 6061 or 7075 aluminum alloy: Lightweight, strong, and resistant to corrosion—ideal for parts like handlebar clamps, footpegs, and engine covers.

- Stainless steel: Extremely durable and rust-resistant—great for parts like brake calipers, sprockets, and hardware.

- Titanium: Ultra-lightweight and strong (but more expensive)—used for high-performance parts like clutch levers or exhaust brackets.

Also, look for parts that have certifications or meet industry standards. For example, brake parts should meet DOT (Department of Transportation) standards for safety, and engine parts should be ISO-certified for quality.

Step 4: Read Reviews and Ask for Recommendations

Before buying a CNC part, read reviews from other riders who have used it. Look for feedback on fitment, performance, and durability. For example, if multiple reviewers say a CNC chain guide wore down quickly, that’s a red flag.

You can also ask for recommendations from fellow riders in online forums (like Reddit’s r/motorcycles) or local motorcycle clubs. Riders who have experience with CNC parts can share insights you won’t find in product descriptions.

Step 5: Compare Prices (But Don’t Sacrifice Quality)

CNC parts range in price from \(20 (for small parts like handlebar ends) to \)500+ (for major parts like engine covers or brake systems). While it’s tempting to go for the cheapest option, remember that low-priced CNC parts may be made from lower-quality materials or have looser tolerances.

Instead of focusing solely on price, compare the value: a slightly more expensive part that lasts longer and performs better is a better investment than a cheap part that needs to be replaced quickly.

Installation and Maintenance Tips for CNC Motorcycle Parts

Once you’ve chosen your CNC parts, proper installation and maintenance are key to getting the most out of them. Here’s what you need to know:

Installation: Do It Yourself or Hire a Pro?

Some CNC parts—like CNC handlebar ends or CNC fuel caps—are easy to install with basic tools (a wrench or screwdriver) and can be done at home. Others, like CNC brake calipers or CNC engine covers, require more advanced knowledge and tools (like torque wrenches or hydraulic brake bleeding kits).

If you’re not confident in your mechanical skills, it’s best to hire a professional mechanic. A poorly installed part can lead to safety issues—for example, a loose CNC brake caliper could fail while you’re riding, putting you at risk.

If you do install parts yourself, follow these tips:

- Read the manufacturer’s installation instructions carefully—don’t skip steps.

- Use the right tools: A torque wrench is essential for parts like wheel spacers or engine covers, as over-tightening can damage the part or your bike.

- Double-check fitment: Before finishing the installation, make sure the part moves freely (if it should) and doesn’t rub against other components.

Maintenance: Keep Your CNC Parts in Top Shape

CNC parts are durable, but they still need regular maintenance to last. Here are some tips for common CNC parts:

- Aluminum parts (e.g., handlebar clamps, footpegs): Clean them regularly with a mild soap and water to remove dirt and grime. Avoid using harsh chemicals, as they can damage the anodized finish. If the finish starts to fade, you can polish it with aluminum polish.

- Stainless steel parts (e.g., brake calipers, sprockets): Wipe them down with a dry cloth after riding to prevent rust. If you ride in wet conditions, you can apply a thin layer of stainless steel protectant to keep them looking new.

- Brake parts (e.g., CNC calipers): Check the brake fluid level regularly and replace it every 2 years (or as recommended by your bike’s manufacturer). Inspect the caliper for leaks—if you see fluid around the piston, have it repaired immediately.

- Engine parts (e.g., CNC covers): Check the bolts regularly to make sure they’re tight. If you notice oil leaks around the cover, replace the gasket and re-tighten the bolts to the correct torque.

Yigu Technology’s View on CNC Motorcycle Parts

At Yigu Technology, we believe CNC motorcycle parts represent the perfect blend of precision engineering and rider-centric design. Our experience in manufacturing high-precision components has shown us that the accuracy of CNC machining directly addresses the pain points riders face—whether it’s inconsistent performance from stock parts or frequent replacements of low-quality aftermarket components. We prioritize using premium materials like 7075 aluminum alloy and stainless steel in our CNC parts, as these materials balance strength, weight, and durability—critical factors for motorcycle components that need to perform in harsh conditions. We also focus on compatibility, ensuring our parts fit a wide range of bike models to make upgrades accessible for more riders. For us, CNC motorcycle parts aren’t just about selling components—they’re about helping riders get more enjoyment, safety, and reliability from their bikes.

FAQ About CNC Motorcycle Parts

1. Are CNC motorcycle parts compatible with all bike models?

No, CNC parts are not one-size-fits-all. Compatibility depends on your bike’s make, model, and year. Always check the manufacturer’s compatibility list before buying, or consult a mechanic if you’re unsure.

2. Do CNC motorcycle parts require special tools to install?

It depends on the part. Small parts like handlebar ends or fuel caps can be installed with basic tools. More complex parts like brake calipers or engine covers may require specialized tools (like torque wrenches or brake bleeding kits). If you’re not sure, hire a professional.

3. Are CNC parts worth the higher cost compared to stock parts?

Yes, in most cases. While CNC parts have a higher upfront cost, they last longer, perform better, and reduce maintenance costs. For example, a CNC sprocket can last 2-3 times longer than a stock plastic sprocket, saving you money on replacements.

4. Can I customize CNC motorcycle parts to match my bike’s style?

Absolutely. Many manufacturers offer custom CNC parts, including different colors, finishes, and designs. You can even work with some companies to create a one-of-a-kind part based on your own design.

5. How long do CNC motorcycle parts typically last?

The lifespan depends on the part, material, and how you use your bike. Aluminum CNC parts (like handlebar clamps) can last 5+ years with proper maintenance. Stainless steel parts (like brake calipers) can last even longer—10+ years in some cases. Off-road use or harsh conditions may shorten the lifespan slightly, but CNC parts still outlast stock parts.