Stainless steel—valued for its strength, corrosion resistance, and versatility—has become a staple in metal 3D printing, bridging the gap between functional prototypes and industrial-grade end parts. For engineers, manufacturers, and designers, understanding how stainless steel is 3D printed, which types work best, and how to overcome common challenges is critical. This article answers the question “Can stainless steel be 3D printed?” by breaking down key materials, technologies, applications, and practical tips.

1. Which Stainless Steels Can Be 3D Printed? Key Types & Use Cases

Not all stainless steels are equally suited for 3D printing. Three grades dominate due to their processability and performance in real-world applications. Below is a detailed breakdown to help you select the right material.

| Stainless Steel Grade | Core Properties | 3D Printing Compatibility | Ideal Application Scenarios |

| 316L Stainless Steel | – Excellent corrosion resistance (resists saltwater, chemicals)- Biocompatible (FDA-approved for medical use)- Good tensile strength (480–550 MPa) | High (most widely used in metal 3D printing) | Medical implants (dental crowns, orthopedic stents), marine components, chemical processing parts |

| 304 Stainless Steel | – General-purpose corrosion resistance- Moderate strength (515–550 MPa)- Cost-effective vs. 316L | Medium (requires parameter optimization for oxidation control) | Industrial brackets, non-critical automotive parts (sensor housings), household appliances |

| 17-4 PH Stainless Steel | – Martensitic precipitation-hardened alloy- High strength after heat treatment (1,100–1,300 MPa)- Good wear resistance | High (ideal for high-stress parts) | Aerospace structural components, high-pressure valves, precision mechanical gears |

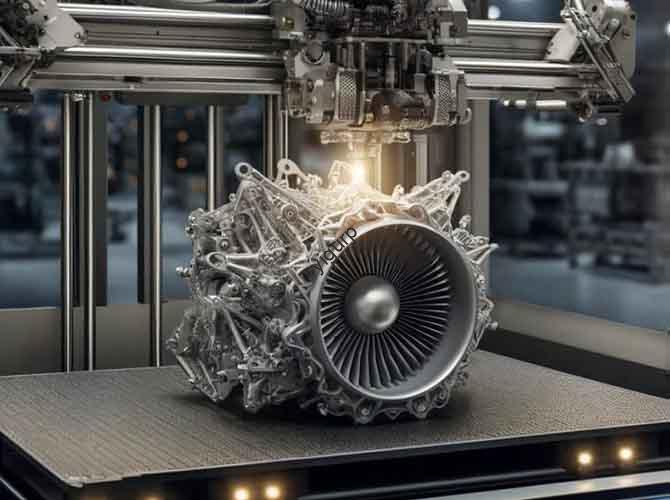

2. How Is Stainless Steel 3D Printed? Core Technologies

Stainless steel relies on three main 3D printing technologies, each with unique trade-offs in cost, precision, and part performance. The table below compares their key features to help you match the process to your project.

| 3D Printing Technology | Working Principle | Key Advantages | Key Limitations | Ideal Use Cases |

| SLM (Selective Laser Melting) | High-energy fiber laser (500–1,000 W) melts stainless steel powder layer by layer in an argon-protected chamber. | – High part density (>99.5%)- Exceptional precision (layer thickness: 20–100 μm)- Suitable for complex geometries (hollow structures, lattice designs) | – High equipment cost (\(200k–\)1M+)- Slow print speed for large parts | Medical implants, aerospace precision components |

| EBM (Electron Beam Melting) | Focused electron beam (1–3 kW) melts powder in a vacuum environment, using high heat to reduce thermal stress. | – Vacuum reduces oxidation risk- Faster print speed than SLM for thick parts- Better for large, thick-walled components | – Lower precision than SLM (layer thickness: 50–200 μm)- Limited to conductive metals | Large industrial molds, heavy-duty automotive parts |

| BJ (Binder Jet Molding) | Liquid binder is jet-printed onto stainless steel powder to bond layers; parts are then sintered in a furnace to densify. | – Lowest cost vs. SLM/EBM- Fast print speed (no melting step)- No support structures needed | – Lower part density (90–95%)- Weaker mechanical properties (30% lower strength than SLM) | Non-load-bearing prototypes, decorative parts, low-stress industrial components |

3. Advantages of 3D Printing Stainless Steel

3D printing unlocks unique benefits that traditional machining (milling, casting) cannot match—especially for complex or low-volume projects:

- Complex Structure Freedom

Traditional methods struggle with internal channels, lattice patterns, or hollow designs (e.g., lightweight aerospace brackets). 3D printing builds parts layer by layer, enabling geometries that reduce weight by 30–50% without sacrificing strength.

- On-Demand Customization

For medical applications (e.g., patient-specific hip implants) or small-batch industrial parts, 3D printing eliminates tooling costs (\(10k–\)50k per mold) and cuts lead time from weeks to days.

- Material Efficiency

Traditional machining wastes 50–70% of stainless steel as scrap. 3D printing uses only the powder needed for the part, reducing waste to <10% (unprinted powder is recyclable).

- Corrosion & Strength Retention

SLM-printed 316L retains 95% of the corrosion resistance of forged 316L, making it suitable for harsh environments (e.g., marine, chemical processing).

4. Key Challenges & Practical Solutions

While 3D printing stainless steel is feasible, three common challenges can impact part quality. Below are proven solutions to mitigate risks:

4.1 Challenge 1: Oxidation During Printing

Stainless steel oxidizes at high temperatures, forming brittle oxide layers that weaken parts.

Solutions:

- Use SLM with argon gas (oxygen content <0.1%) or EBM’s vacuum chamber to isolate powder.

- Pre-dry stainless steel powder (80–120°C for 2–4 hours) to remove moisture, which exacerbates oxidation.

4.2 Challenge 2: Thermal Stress Cracks

Rapid heating/cooling during printing causes internal stress, leading to cracks—especially in thick parts.

Solutions:

- Optimize parameters: For SLM, set laser power to 600–800 W, scanning speed to 400–600 mm/s, and layer thickness to 50 μm (balances heat input and cooling).

- Post-print stress-relief annealing: Heat parts to 800–900°C for 1–2 hours, then cool slowly to release internal stress.

4.3 Challenge 3: Post-Processing Complexity

Raw 3D printed parts require finishing to meet accuracy and performance standards.

Solutions:

- Remove supports with wire EDM (for precision parts) or mechanical cutting (for non-critical parts).

- For corrosion resistance: Polish parts to a Ra <0.8 μm surface finish or apply a passivation coating (e.g., nitric acid treatment).

5. Yigu Technology’s Perspective on 3D Printing Stainless Steel

At Yigu Technology, we see 3D printed stainless steel as a “bridge material”—it balances performance, cost, and versatility for most industrial needs. Many clients overspend on SLM when BJ works for prototypes, or choose 316L for non-corrosive applications (wasting 20–30% in material costs). Our advice: Start with a “needs-first” assessment—use 304 for general parts, 316L for corrosion/medical use, and 17-4 PH for high-strength needs. For small batches (<100 parts), SLM delivers the best value; for large prototypes, BJ cuts costs by 50%. We also optimize parameters in-house: For a recent client’s 316L dental crowns, adjusting SLM laser speed to 500 mm/s reduced cracks by 80% and improved density to 99.8%. This practical approach ensures clients get high-quality parts without unnecessary expenses.

FAQ: Common Questions About 3D Printing Stainless Steel

- Q: Can 3D printed stainless steel match the strength of traditionally forged stainless steel?

A: Yes—with SLM. SLM-printed 316L has a tensile strength of 480–550 MPa, identical to forged 316L. EBM-printed parts are slightly weaker (450–500 MPa), while BJ parts are 30% weaker (better for non-load-bearing use).

- Q: Is 3D printing stainless steel cost-effective for large-batch production (>1,000 parts)?

A: No—traditional casting is cheaper for large batches. 3D printing shines for small batches (<500 parts) or complex designs; for 1,000+ parts, casting’s lower per-unit cost (50–70% less than SLM) makes it better.

- Q: Do 3D printed stainless steel parts require post-processing?

A: Yes—minimum post-processing includes support removal and stress-relief annealing (to prevent cracking). For critical parts (e.g., medical implants), additional polishing or passivation is needed to improve corrosion resistance and biocompatibility.