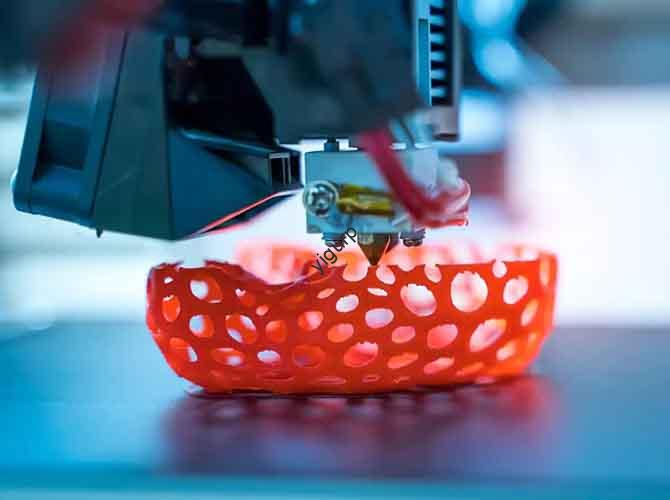

3D printing speed directly impacts project timelines, especially in industries like healthcare, aerospace, and manufacturing. Whether you’re printing a custom medical implant or a prototype, understanding what drives speed—and how to balance it with quality—is critical. This article breaks down the core factors affecting 3D printing speed, compares technologies, and offers practical insights to help you optimize your workflow.

1. How 3D Printing Technologies Impact Speed

Different 3D printing technologies have distinct speed capabilities, shaped by their core working principles. The table below compares the typical speed ranges and key influencing factors for four common technologies:

| Technology | Typical Speed Range | Key Speed-Limiting Factors | Speed Advantages |

| FDM (Fused Deposition Molding) | 10–100 mm/s | Printhead movement speed, material extrusion rate, model complexity | Low cost; easy to use for basic parts |

| SLA (Stereolithography) | Tens–100+ mm/s | Layer thickness, resin curing speed, laser/LED power | Fast planar curing; ideal for high-detail parts |

| SLS (Selective Laser Sintering) | Tens of mm/s | Laser scanning precision, powder bed heating time | Handles complex geometries without supports |

| PolyJet (Multi-Material Jetting) | Variable (fast for small parts) | Number of printheads, part size, precision requirements | Multi-material printing; quick for small batches |

Real-World Speed Example

- An entry-level FDM printer takes ~4 hours to print a 5cm × 5cm × 5cm simple cube at 20 mm/s.

- A high-speed SLA printer can finish the same cube in ~1.5 hours at 80 mm/s, thanks to its layer-by-layer resin curing (no point-by-point material deposition like FDM).

2. Print Object Characteristics: Size and Complexity

Two key properties of the printed object—size and complexity—directly slow down or speed up the process.

A. Size: Larger Parts = Longer Print Times

Printing speed decreases as part size increases because:

- Each layer covers a larger area, requiring more time for the printhead/laser to traverse.

- More material needs to be extruded (FDM) or cured (SLA/SLS), extending total runtime.

Example: A 10cm × 10cm × 10cm cube takes 3–4x longer to print than a 5cm × 5cm × 5cm cube (FDM, same layer height).

B. Complexity: Fine Details Slow Things Down

Models with intricate features (e.g., hollow structures, thin walls, small holes) require slower speeds to ensure accuracy. Here’s why:

- The printhead/laser must start/stop frequently (FDM) or adjust scanning paths (SLA/SLS) to avoid errors.

- Delicate details need more precise control (e.g., lower extrusion speed for thin walls), increasing print time.

Case Study: An architectural model with complex hollow interiors takes 2x longer to print than a solid block of the same size (SLS technology).

3. Hardware Configuration: Printer Performance Matters

A printer’s hardware directly determines its maximum speed potential. Key components to consider include:

A. Printer Performance (Motors, Rails, Control Systems)

- Motors: High-performance servo motors (common in industrial printers) enable faster, smoother movement of the printhead/laser than basic stepper motors (entry-level printers).

- Rails: Linear guides (vs. basic rods) reduce friction, allowing faster speeds without sacrificing precision.

- Control Systems: Advanced firmware (e.g., Marlin 2.0) optimizes movement paths, cutting down on unnecessary delays.

Comparison: An industrial FDM printer (servo motors, linear rails) can print at 80–100 mm/s, while a consumer model (stepper motors, basic rods) tops out at 40–60 mm/s.

B. Number of Printheads

Multiple printheads boost speed by enabling parallel work:

- Dual-printhead FDM printers: One printhead handles the main part, while the other prints support structures (no need to pause and switch tasks).

- Multi-printhead PolyJet printers: Print multiple small parts or different materials simultaneously, reducing total batch time.

4. Yigu Technology’s Perspective on 3D Printing Speed

At Yigu Technology, we balance speed and quality to meet medical and industrial needs. For 3D printed medical devices (e.g., interbody fusion devices), we optimize hardware (high-precision servo motors, dual linear rails) and software (AI-driven path planning) to cut print time by 20–25% without compromising accuracy. We also tailor speed settings to part complexity: e.g., 50–60 mm/s for porous fusion devices (to ensure pore precision) and 70–80 mm/s for solid components. Our goal is to deliver fast, reliable prints that meet strict industry standards.

5. FAQ: Common Questions About 3D Printing Speed

Q1: Can I increase 3D printing speed without losing quality?

Yes—within limits. For simple parts, you can raise print speed (e.g., from 40 to 60 mm/s for FDM) if your printer has strong motors/rails. For complex parts, prioritize precision over speed to avoid defects.

Q2: Why is my SLA printer slower than advertised?

Advertised speeds often reflect ideal conditions (simple parts, thin layers). Slowdowns occur with thick layers (slower curing) or complex models (frequent path adjustments). Check your layer height and model geometry to optimize.

Q3: Does faster 3D printing use more material?

No—material usage depends on part volume (not speed). However, faster speeds may increase material waste if errors (e.g., stringing in FDM) occur, so balance speed with quality to minimize waste.