1. CNC Sheet Metal Design Basics

For newcomers to CNC sheet metal design, building a solid foundation is key to avoiding post-rework. Many designers tend to ignore design specifications and standards in the early stages, resulting in products not being able to adapt to the processing process – there have been customers who did not follow the GB/T 15055-2015 sheet metal tolerance standard, and 30% of the products had excessive assembly gaps during mass production.

The core of the basic principle of sheet metal processing is “material plastic deformation + precise cutting”, which simply means processing metal sheets into target shapes through laser cutting, bending and other processes. Novices need to focus on the relationship between sheet metal thickness and strength: taking 304 stainless steel as an example, every 1mm increase in thickness increases the bending strength by about 18%, but the processing difficulty and cost will also increase simultaneously, and it is recommended to choose a thickness of 1.2-2.0mm for conventional equipment shells.

Common design mistakes need to be kept in mind three points: first, the hole position should not be less than 1.5 times the aperture from the edge of the plate, otherwise it is easy to crack; second, avoid sharp corners at the bends, and reserve R angles (usually R≥1.5mm); third, avoid designing closed cavities to leave space for processing and assembly. It is recommended to start with SolidWorks, whose sheet metal module can automatically generate unfolded drawings, and novices need to focus on mastering the parameter settings of “bending deduction” and “K factor” (0.35 for conventional carbon steel K factor).

2. CNC sheet metal materials and characteristics

Sheet metal material types are mainly divided into three categories: stainless steel, aluminum, and carbon steel, and their performance differences directly determine product applicability:

| Material type | Representative grade | Tensile Strength (MPa) | Corrosion resistance | Cost level | Applicable scenarios |

| stainless steel | 304/316 | 515-620 | excellent | Middle and high | Medical equipment, outdoor equipment |

| aluminium | 6061/5052 | 205-310 | good | Medium | Aerospace, electronic enclosures |

| carbon steel | Q235/SPCC | 370-460 | So so | low | Industrial equipment, brackets |

For example, in the aerospace field, 6061 aluminum alloy is preferred, with a yield strength of 276MPa, and the advantages of lightweight material selection are obvious – it is 30% lighter than carbon steel of the same strength, which can reduce the energy consumption of the whole machine. In the surface treatment process, spraying is suitable for indoor equipment (salt spray resistance test up to 48 hours), electroplating (galvanized / chrome plating) is suitable for components that require electrical conductivity, anodizing (mainly for aluminum) improves wear resistance and aesthetics, and a wide range of colors are available.

Material thickness and bending coefficient are key to design: for example, for 1.5mm thick Q235 carbon steel, the bending coefficient is usually 1.8mm at a bending angle of 90° (slightly different equipment); while aluminum has better plasticity, and the bending coefficient of the same thickness can be reduced by 0.2-0.3mm. In terms of material sustainability and recycling, the recycling rate of aluminum has reached more than 95%, making it a priority for environmental protection. 304 stainless steel also has a high recycling value, which is in line with the trend of green manufacturing. In special alloy applications, 316 stainless steel is often used in equipment near the seaside or in chemical environments due to its 50% higher corrosion resistance than 304 due to its molybdenum element.

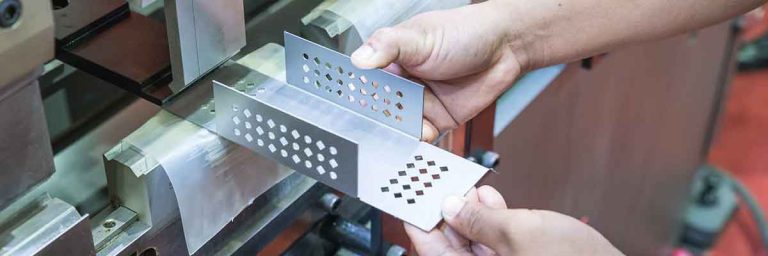

3. CNC sheet metal design process and fabrication

The sheet metal bending process and design should follow the principle of “inside first and then outside, small first and then large”, and complex structures need to split the bending steps. When designing a chassis for an electronic equipment manufacturer, the assembly error was controlled within ±0.1mm due to the use of the “continuous bending + locating pin” process, which met the installation needs of precision components. In terms of laser cutting technology and parameters, the optimal speed for fiber laser cutting carbon steel is 1.5-3m/min (thickness 2mm), the cutting aperture can be as little as 0.8 times the thickness of the material (such as 1mm thick plate can cut 0.8mm aperture), and the tolerance and precision control can reach ±0.05mm.

Stamping and mold design are suitable for mass production, such as sheet metal brackets in auto parts, which use continuous die stamping, which increases production efficiency by 80% compared to laser cutting, but the mold cost is higher (about 5-100,000 yuan for a single set of molds), and it is suitable for products with an annual output of more than 100,000 pieces. In the welding and splicing method, argon arc welding is suitable for stainless steel and aluminum (weld strength up to 80% of the base metal), and resistance spot welding is suitable for thin plate splicing (small deformation), and the welding space needs to be reserved during design (usually the weld width is ≥ 3mm).

Reduce processing deformation skills to share three practical experiences: first, symmetrical design to avoid uneven uneven force on one side; second, increase the stiffener (width ≥ 8mm, height ≥ 15mm) to improve the rigidity of the structure; The third is to adopt “step-by-step processing”, which is annealed after cutting and then bent. Mass production optimization can reduce mold change and debugging time by standardizing hole positions and unifying bending angles, and a home appliance company shortened the production cycle of sheet metal parts from 20 seconds / piece to 12 seconds / piece through optimized design.

4. CNC Sheet Metal Design Software and Tools

In CAD software applications, SolidWorks and AutoCAD are the mainstream of the industry: SolidWorks is good at 3D modeling and automatic generation of unfolding drawings, which is suitable for complex structural design; AutoCAD is more efficient at drawing 2D drawings, especially for quick drawings of simple sheet metal parts. CAM programming and path optimization recommends Mastercam, which improves material utilization (typically from 75% to over 90%) and path optimization reduces laser head empty travel and improves processing efficiency.

Sheet metal design plug-ins and tools can greatly improve productivity: for example, SolidWorks’ “Sheet Metal Wizard” automatically checks for design errors, and “DXF Import Wizard” can quickly process customer-provided DXF files; AutoCAD’s Sheet Metal Toolset includes useful features such as bend tables, unfolded calculations, and more. 3D modeling and unfolding drawing generation need to be noted that the unfolding drawing must be marked with key information such as material thickness, bending direction, and R-angle size to avoid processing misunderstandings.

In file format conversion, the DXF format is the standard format for sheet metal processing (the most compatible), and the STEP format is suitable for 3D model transfer (preserving complete structural information). Design automation scripts can be written in VBA or Python, such as batch modification of hole coordinates, automatic generation of BOMs, and a mechanical design institute can reduce repetitive design work by 60% through script development. Autodesk Fusion 360 is recommended for the cloud-based collaborative design platform, which supports real-time collaboration between multiple teams and facilitates the integration of designers and processing plants.

5. CNC sheet metal application fields and cases

Chassis and enclosure design are the most common application scenarios, and the core requirements are protection, heat dissipation and assembly convenience. For example, the sheet metal chassis designed for an industrial controller uses 1.5mm SPCC carbon steel + electrostatic spraying process, and meets the IP54 protection level through a reasonable layout of heat dissipation holes (hole diameter 3mm, hole spacing 10mm), while the weight is controlled within 8kg.

An aircraft parts supplier uses 5052 aluminum alloy to produce cabin interior parts with a tolerance of ±0.03mm and passed 20,000 vibration tests. In the manufacturing of auto parts, sheet metal parts account for 15-20% of the weight of the vehicle, and a new energy vehicle company uses high-strength carbon steel (Q960) to manufacture the frame, which reduces the weight by 10% and improves the impact resistance by 30%.

Sheet metal applications for medical devices focus on corrosion resistance and cleanliness, such as surgical instruments made of 316 stainless steel, electropolished for easy cleaning without dead ends, and ISO 13485 medical certification. Customized sheet metal solutions need to combine industry characteristics, such as partitions made of color-coated steel plates in the field of home and building decoration, which are both aesthetically pleasing and practical; The Industrial Equipment Shield uses a transparent PC board combined with sheet metal to protect and facilitate the observation of equipment in operation.

In terms of industry trends and prospects, with the development of intelligent manufacturing, CNC sheet metal design is developing in the direction of “digitalization, intelligence, and greening”: the integration of digital design and manufacturing (seamless connection of CAD/CAM/CAE), the expansion of the application of lightweight materials (aluminum alloys, composite materials), and the combination of 3D printing and traditional sheet metal processes will become the mainstream. According to industry data, the global CNC sheet metal market size will reach $85 billion in 2025, with a compound annual growth rate of approximately 6.8%.

6. FAQ:

- When it comes to designing CNC sheet metal parts, what is the easiest thing to overlook?

Answer: it is most likely to ignore the matching of bending coefficient and material characteristics and the distance between the hole and the edge, it is recommended to refer to the design of similar mature products in the early stage, or directly consult the processing plant to obtain a bending table.

- What is the difference between the bending process of stainless steel and aluminum?

Answer: aluminum has better plasticity, the bending R angle can be smaller (≥1mm), and the bending coefficient is 0.2-0.3mm smaller than stainless steel; Stainless steel needs to avoid cold working cracking, and thick plates need to be preheated (≥ 100°C) before bending.

- How can I improve sheet metal material utilization?

A: Material utilization can typically be increased from 70-75% to 85-90% through nesting with CAM software, optimizing part shape (reducing scrap), and nesting parts with different thicknesses.

- Sheet metal design software choice, SolidWorks or AutoCAD which one to choose?

Answer: For complex structures that require 3D modeling and automatic unfolding, choose SolidWorks; Simple parts, quick 2D drawings, choose AutoCAD, the two can be used complementarily (2D drawings drawn by AutoCAD can be imported into SolidWorks modeling).

- What are the special requirements for the selection of medical equipment sheet metal parts?

A: 316 stainless steel or 6061 aluminum alloy should be preferred, and the surface treatment should be biocompatible (no harmful substance precipitation) and can withstand high-temperature sterilization (usually ≥ 120°C).