You’ve spent hours 3D printing a part—only to find it covered in support marks, layer lines, or rough edges. Sound familiar? Post-processing for 3D printing is the missing step that turns “good” prints into “professional-grade” ones. Whether you’re making a PLA figurine, an ABS prototype, or a resin model, the right post-processing techniques fix flaws, boost durability, and elevate the final look. This guide breaks down every key method, solves common issues, and helps you choose the best approach for your project.

1. Why Post-Processing for 3D Printing Matters

Think of 3D printing like baking a cake: the printer “bakes” the base, but post-processing is the frosting, decoration, and final touch that makes it ready to serve. Without it, even the most well-designed print will have:

- Support Marks: Ugly indentations or rough spots where supports were attached (common in FDM and resin prints).

- Layer Lines: Visible ridges between printed layers (especially noticeable in PLA and ABS parts).

- Dimensional Imperfections: Small gaps or uneven edges that make the part unusable for tight-fit projects (e.g., a 3D-printed gear that won’t mesh with others).

For example, a 3D-printed PLA phone case straight from the printer might have rough edges that scratch your hand. A quick sanding and polishing (post-processing steps) turn it into a smooth, sleek accessory—ready for daily use.

2. 8 Essential Post-Processing Techniques for 3D Prints

Below are the most common post-processing methods, organized by goal (e.g., removing supports, smoothing surfaces). Each includes step-by-step instructions and pro tips to avoid mistakes.

Technique 1: Support Removal (Fixing Support Marks)

Supports are necessary for overhanging parts (e.g., a figurine’s outstretched arm), but they leave marks if not removed properly. There are two main methods:

| Method | How to Do It | Best For | Pros | Cons |

| Manual Removal | 1. Use needle-nose pliers or a support removal tool to grip supports near the print. 2. Pull gently (not forcefully) to avoid breaking the print. 3. Sand leftover marks with 400-grit sandpaper. | FDM prints (PLA, ABS) with large, easy-to-reach supports. | No special equipment needed; fast for simple supports. | Risk of breaking small parts (e.g., thin figurine limbs); leaves marks that need sanding. |

| Water-Soluble Supports | 1. Submerge the print (with supports) in warm water (40–60°C). 2. Stir occasionally—supports dissolve in 1–4 hours (depending on size). 3. Rinse the print with cold water and let it dry. | Resin prints or FDM prints with complex internal supports (e.g., a hollow model). | No marks left; ideal for hard-to-reach supports. | Requires a dual-extruder 3D printer (e.g., Chuangxiang 3D CR-5S CR-X); soluble supports cost more than regular PLA. |

Technique 2: Sanding & Polishing (Smoothing Layer Lines)

Sanding removes layer lines and support marks, while polishing makes the surface shiny. Follow this linear workflow for best results:

- Start with Low-Grit Sandpaper: Use 120–240 grit sandpaper to remove large layer lines or rough spots. Sand in circular motions—avoid focusing on one area too long (this can melt PLA or create uneven surfaces).

- Move to High-Grit Sandpaper: Switch to 400–800 grit to smooth the surface further. For resin prints, use 1000–2000 grit for a near-mirror finish.

- Polish the Print:

- For PLA: Apply a small amount of acrylic glue to a soft cloth and rub the surface in circular motions. The glue slightly melts PLA, filling in tiny grooves—stop after 1–2 minutes to avoid losing dimensional accuracy.

- For ABS: Use acetone vapor (see Technique 3) for a smooth, glossy finish.

Pro Tip: Wet-sand with water (use waterproof sandpaper) to reduce dust and make sanding smoother—this works especially well for PLA prints.

Technique 3: Surface Smoothing (For ABS & Resin Prints)

ABS and resin prints benefit from extra smoothing to eliminate even the finest layer lines. The most effective method for ABS is acetone vapor smoothing:

- Prepare a Container: Pour 1–2 cm of acetone into a large, airtight container (e.g., a mason jar).

- Elevate the Print: Place the ABS print on a platform (e.g., a small jar lid) inside the container—make sure it doesn’t touch the acetone.

- Seal & Wait: Close the container and let the print sit for 5–15 minutes. The acetone vapor melts the outer layer of ABS, smoothing layer lines.

- Remove & Dry: Take the print out and let it air-dry for 30 minutes—avoid touching it while wet (acetone is flammable and can irritate skin).

Warning: Work in a well-ventilated area and wear gloves—acetone fumes are harmful if inhaled.

Technique 4: Bonding (Joining Multiple Print Parts)

If your design is too large for one print (e.g., a life-size Gundam model), use bonding to connect pieces. Choose the right adhesive for your material:

| Adhesive Type | Best For | How to Use It | Key Tip |

| Hot Melt Glue | PLA prints (temporary or low-stress bonds). | Heat the glue gun, apply a thin line of glue to one part, and press the pieces together for 30 seconds. | Avoid using on ABS (hot glue can melt ABS slightly). |

| Acrylic Adhesive | ABS or resin prints (strong, permanent bonds). | Apply a small amount to both surfaces, let it sit for 10 seconds, then press together for 5 minutes. | Sand the bonding area first for better adhesion. |

| 502 Glue (Cyanoacrylate) | Small resin parts (e.g., figurine hands). | Use a toothpick to apply a tiny dot of glue—too much will leave a white residue. | Work fast—502 glue dries in 10–20 seconds. |

Technique 5: Filling (Fixing Gaps & Cracks)

Small gaps (e.g., between bonded parts) or cracks can ruin a print’s look and strength. Use filling materials to fix them:

- Choose a Filler:

- Atomic Ash/AB Soil: Best for ABS or metal prints—mix the two components (per the package instructions) and apply to gaps with a putty knife.

- Water-Based Filler: Ideal for PLA—non-toxic and easy to sand.

- Apply the Filler: Fill the gap slightly above the surface (it will shrink as it dries).

- Sand After Drying: Once dry (1–2 hours for water-based filler, 4–6 hours for atomic ash), sand with 400-grit sandpaper until smooth.

Technique 6: Coloring (Adding Color & Personality)

Coloring turns plain prints into eye-catching pieces. The two most popular methods are:

- Airbrush Coloring:

- Thin oil-based paint with a solvent (per the paint’s instructions).

- Spray in a well-ventilated area (use a mask!) with light, even coats—let each coat dry for 15–30 minutes.

- Add details (e.g., stripes) with a small brush once the base coat is dry.

Best For: Large prints (e.g., a 3D-printed prop sword) or prints with complex shapes.

- Hand Painting:

- Use acrylic paint and small brushes (size 0–3 for details).

- Start with a base coat—let it dry completely (1 hour) before adding layers.

- Use a dry brush for texture (e.g., a “weathered” look on a model car).

Best For: Small prints (e.g., resin figurines) or detailed work (e.g., facial features).

Technique 7: Spray Painting (Professional-Grade Finish)

Spray painting is faster than hand painting and gives a smooth, even coat. Follow these steps:

- Prep the Print: Sand with 400–800 grit sandpaper and clean with isopropyl alcohol (removes dust and oil).

- Apply Primer: Spray a thin coat of primer (choose a color that matches your top coat—e.g., white primer for light colors). Let it dry for 1 hour.

- Spray Top Coat: Hold the can 20–30 cm from the print and spray in sweeping motions. Apply 2–3 thin coats (let each dry 30 minutes) instead of one thick coat (avoids drips).

- Seal (Optional): Add a clear coat (matte or glossy) to protect the paint from scratches.

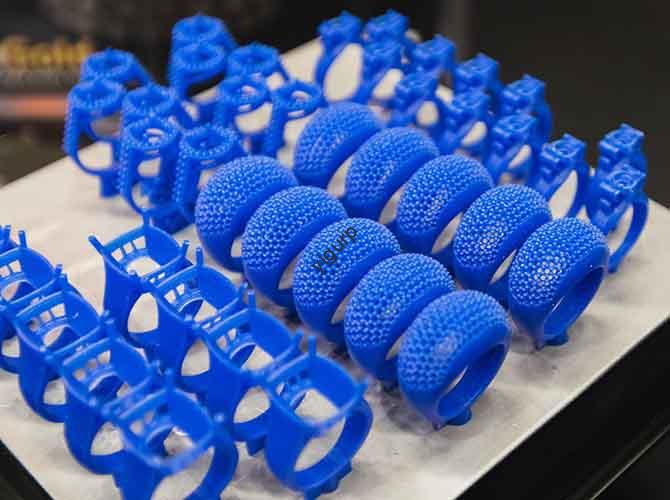

Technique 8: Silicone Molding & Vacuum Forming (Mass-Producing Prints)

If you need multiple copies of a print (e.g., 50 custom keychains), use these advanced methods:

- Silicone Molding:

- Make a mold box around your 3D print (use cardboard or 3D-printed plastic).

- Mix silicone rubber (per instructions) and pour it into the box—cover the print completely.

- Let the silicone cure (6–24 hours), then remove the print. The mold is ready to cast resin or plastic copies.

- Vacuum Forming:

- Strengthen your 3D print (increase wall thickness to 3–5mm in slicing software) to withstand vacuum pressure.

- Heat a plastic sheet (e.g., PETG) with an industrial vacuum forming machine until it’s soft.

- Use vacuum pressure to press the plastic sheet onto the 3D print—let it cool, then remove the mold.

Best For: Making plastic containers or simple parts (e.g., toy shells).

3. How to Choose the Right Post-Processing Techniques

With so many methods, how do you pick the right ones? Use this 3-step checklist:

- What’s Your Material?

- PLA: Focus on sanding, acrylic glue polishing, and water-based filling (avoid acetone—it melts PLA).

- ABS: Use acetone vapor smoothing, atomic ash filling, and acrylic adhesive bonding.

- Resin: Prioritize water-soluble supports, fine sanding (1000+ grit), and hand painting.

- What’s Your Goal?

- Fix flaws: Use support removal, filling, and sanding.

- Boost appearance: Add coloring, spray painting, or polishing.

- Mass-produce: Choose silicone molding or vacuum forming.

- What’s Your Skill Level?

- Beginner: Start with manual support removal, sanding, and hand painting (no special equipment needed).

- Advanced: Try acetone smoothing, silicone molding, or vacuum forming (requires more tools and practice).

4. Yigu Technology’s Perspective on Post-Processing for 3D Printing

At Yigu Technology, we see post-processing as the “secret sauce” that makes 3D prints market-ready. The biggest mistake we see? Skipping sanding or using the wrong grit—many hobbyists jump to painting with rough surfaces, leading to uneven color and peeling.

Our pro tip: For clients printing functional parts (e.g., automotive prototypes), we recommend a “sand-polish-bond” workflow—this ensures parts are smooth, strong, and fit perfectly. We also help industrial clients scale post-processing: for example, a toy manufacturer now uses our automated sanding machines to finish 1,000+ PLA toys daily (cutting labor time by 70%). As 3D printing materials evolve, we’re testing new post-processing methods—like UV curing for resin prints—to make the process faster and more accessible.

FAQ: Your Top Post-Processing for 3D Printing Questions Answered

Q1: Can I skip post-processing for PLA prints?

A1: It depends on your use case. If you’re making a rough prototype (e.g., a test fit for a part), you can skip it. But for functional or decorative prints (e.g., a phone case or figurine), post-processing (at minimum, sanding) is needed to remove sharp edges and layer lines—otherwise, the print will look unprofessional and may not work as intended.

Q2: How long does post-processing take for a small PLA print (e.g., a 5cm figurine)?

A2: For a beginner, it takes 1–2 hours: 30 minutes for manual support removal, 45 minutes for sanding (120–800 grit), and 15 minutes for hand painting. Advanced users can cut this to 45 minutes with faster tools (e.g., an electric sander).

Q3: Is acetone safe to use for ABS smoothing?

A3: It’s safe if used correctly. Always work in a well-ventilated area (open windows or use a fume hood) and wear nitrile gloves (acetone irritates skin). Never pour acetone directly on the print (use vapor instead)—this avoids melting the part too much. Keep acetone away from heat sources (it’s flammable).