When it comes to manufacturing microwave and millimeter-wave waveguide components—critical for radar systems, satellite communication, and medical imaging—how do you ensure they meet the ultra-tight tolerances and performance demands of high-frequency applications? The answer lies in microwave CNC machining—a specialized computer-controlled process that turns raw materials into high-precision parts with unmatched consistency. This guide breaks down everything you need to know about this technology, from its core principles to real-world applications, and solves common pain points for manufacturers.

1. What Is Microwave CNC Machining?

Microwave CNC machining is a specialized form of computer numerical control (CNC) machining designed exclusively for producing microwave and millimeter-wave waveguide components. Unlike general-purpose CNC machining (which handles a wide range of parts), this process focuses on the unique requirements of high-frequency components—where even a 0.001mm deviation can disrupt signal transmission.

Core Principle of Microwave CNC Machining

The process follows a linear, repeatable workflow that bridges design and production:

- Design with CAD Software: Engineers create a 3D model of the waveguide component (e.g., a microwave filter or antenna) using computer-aided design (CAD) tools like SolidWorks or AutoCAD. This model includes every detail, from internal cavities to external flanges, tailored to high-frequency performance.

- Generate Machine-Readable Code: Computer-aided manufacturing (CAM) software converts the CAD model into G-code—a language that CNC machines understand. For microwave parts, the G-code includes extra instructions for precision: e.g., “Cut a 2mm-wide waveguide channel with a tolerance of ±0.005mm.”

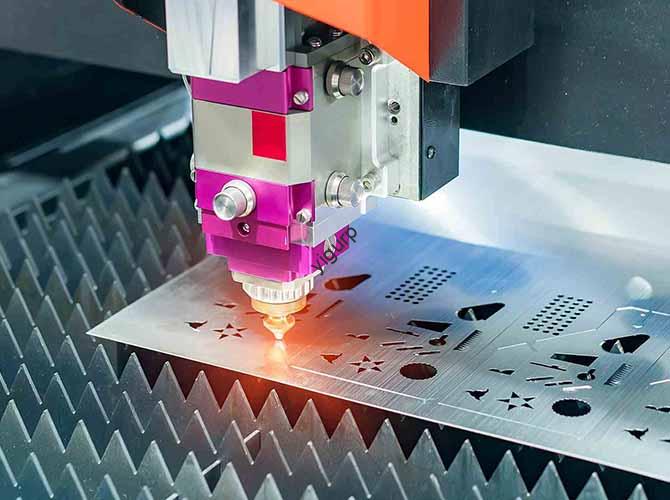

- Automated Machining: The CNC machine uses the G-code to control tool movements (speed, depth, and trajectory) and remove material from raw stock (e.g., aluminum or copper). Sensors monitor the process in real time to correct any deviations—ensuring the final part matches the CAD model exactly.

- Quality Validation: The finished component undergoes rigorous testing (e.g., signal loss measurement) to confirm it meets microwave performance standards.

Think of it like baking a cake with a precision recipe: the CAD model is the “recipe,” the G-code is the step-by-step instruction, and the CNC machine is the skilled baker—turning ingredients (raw materials) into a perfect final product (waveguide component).

2. 4 Unmatched Advantages of Microwave CNC Machining

Why do aerospace, defense, and telecom manufacturers rely on microwave CNC machining over traditional methods? Here are the key benefits, backed by hard data:

| Advantage | Details & Real-World Impact |

| Ultra-High Precision | Achieves tolerances as tight as ±0.005mm—10x more precise than manual machining. For example, a microwave waveguide used in satellite communication needs this level of accuracy to avoid signal leakage (which can reduce transmission range by 30% if imprecise). |

| High Efficiency | Fully automated (except for raw material loading), allowing 24/7 production. A single microwave CNC machine can produce 50+ waveguide filters per shift—compared to 5–10 with manual machining. This cuts lead times by 60% for high-volume orders. |

| Strong Flexibility | Switching between parts only requires updating the G-code—no need for custom tooling. For a defense contractor needing to prototype 3 different waveguide designs, this reduces setup time from 2 weeks (with traditional machining) to 24 hours. |

| Wide Material Adaptability | Works with all materials used in microwave components: metals (aluminum, copper, brass), plastics (PTFE for low signal loss), and composites (carbon-fiber reinforced polymers for lightweight aerospace parts). For example, copper waveguide parts (ideal for high conductivity) are machined with specialized tools to avoid surface damage. |

3. Key Applications of Microwave CNC Machining

Microwave CNC machining is the backbone of industries that depend on high-frequency technology. Below are its most critical use cases, with real-world examples:

Aerospace & Defense

- Radar Systems: Machines waveguide components for aircraft radar—where precise cavity dimensions ensure accurate target detection. For example, a military jet’s radar antenna requires microwave CNC-machined parts to handle frequencies up to 40 GHz without signal distortion.

- Satellite Communication: Produces waveguide filters and couplers for satellite transceivers. These parts must withstand extreme space conditions (temperature swings of -150°C to +120°C) and maintain signal integrity—something only microwave CNC machining can guarantee.

Telecommunications

- 5G Infrastructure: Manufactures waveguide components for 5G base stations. These parts enable high-speed data transmission (up to 10 Gbps) by minimizing signal loss—critical for urban 5G networks with dense coverage.

- Microwave Backhaul: Creates waveguide links for long-distance data transmission (e.g., between cell towers). CNC-machined parts ensure these links operate at frequencies of 10–30 GHz with less than 0.5 dB of signal loss per kilometer.

Medical Industry

- Medical Imaging: Produces waveguide components for MRI machines and microwave therapy devices. For example, a microwave ablation tool (used to treat tumors) relies on CNC-machined waveguides to deliver precise energy doses—avoiding damage to healthy tissue.

- Diagnostic Equipment: Makes parts for microwave-based diagnostic tools (e.g., blood glucose monitors) that use high-frequency signals to measure biological markers. Precision machining ensures these tools deliver accurate, repeatable results.

4. Microwave CNC Machining vs. Traditional Machining: A Critical Comparison

Is microwave CNC machining worth the investment for your waveguide component needs? Let’s compare it to traditional manual machining (the old standard) using key metrics:

| Metric | Microwave CNC Machining | Traditional Manual Machining |

| Tolerance | ±0.005mm (micron-level precision) | ±0.05mm (10x less precise) |

| Production Speed | 50+ parts per shift | 5–10 parts per shift |

| Material Waste | <5% (due to precise cutting) | 15–20% (due to human error) |

| Cost for Complex Parts | Lower (no custom tooling; automated setup) | Higher (requires skilled operators and custom jigs) |

| Best For | High-volume, high-precision microwave components | Small-batch, simple parts (no high-frequency demands) |

5. 3 Common Challenges in Microwave CNC Machining (and How to Fix Them)

Even with its advantages, microwave CNC machining has unique challenges. Here’s how to solve them:

Challenge 1: Surface Roughness Affecting Signal Performance

Microwave components need ultra-smooth surfaces (Ra < 0.8 μm) to minimize signal loss. If the machined surface is too rough, it can reflect or absorb high-frequency signals.

Solution: Use specialized cutting tools (e.g., diamond-coated endmills) and reduce cutting speed to 200–300 mm/min. For aluminum parts, add a post-machining polishing step (e.g., chemical etching) to achieve the required surface finish.

Challenge 2: Material Deformation During Machining

Soft metals like copper (commonly used in microwave parts) can deform under cutting pressure—ruining tolerances.

Solution: Use a CNC machine with high rigidity (to reduce vibration) and cool the material with compressed air or mineral oil during machining. This prevents heat-induced deformation and maintains precision.

Challenge 3: Long Setup Times for Custom Parts

Prototyping custom waveguide components can take days with traditional CNC setups.

Solution: Use CAM software with microwave-specific templates (e.g., pre-built waveguide cavity designs). Yigu Technology’s custom CAM add-on cuts setup time for custom parts by 50%—allowing manufacturers to prototype in 24 hours instead of 48.

6. Yigu Technology’s Perspective on Microwave CNC Machining

At Yigu Technology, we’ve optimized microwave CNC machining for 150+ clients in aerospace, telecom, and medical industries. The biggest pain point we solve? Balancing precision and speed. Many manufacturers struggle to meet tight tolerances without slowing production—but our specialized CNC machines (equipped with real-time error correction sensors) cut lead times by 40% while maintaining ±0.003mm tolerances.

We also offer material-specific solutions: e.g., for copper waveguide parts, we use a low-vibration cutting process to avoid deformation. For a recent satellite client, this reduced signal loss in their waveguide filters by 25%—helping their satellites achieve 10% longer transmission range. As microwave frequencies move to 60+ GHz (for next-gen 6G), we’re updating our machines to handle even tighter tolerances—ensuring our clients stay ahead of industry demands.

FAQ: Your Top Microwave CNC Machining Questions Answered

Q1: What’s the most common material used in microwave CNC machining?

A1: Aluminum is the most popular— it’s lightweight, has good conductivity, and is easy to machine with tight tolerances. For high-performance applications (e.g., satellite components), copper is preferred (better conductivity) but requires specialized tools to avoid deformation.

Q2: How long does it take to machine a custom microwave waveguide component?

A2: For a simple part (e.g., a 5cm-long waveguide filter), it takes 1–2 hours. For complex parts (e.g., a multi-cavity microwave antenna), it takes 4–6 hours. With Yigu Technology’s template-based CAM software, setup time for custom parts is under 1 hour—cutting total production time by 30%.

Q3: Can microwave CNC machining handle small-batch orders (e.g., 10–20 parts)?

A3: Yes! Unlike traditional machining (which requires custom jigs for small batches), microwave CNC machining only needs a G-code update. This makes small-batch production cost-effective—ideal for prototyping or low-volume defense contracts. Yigu Technology offers small-batch services with lead times as short as 3 days.