If you’re involved in product development, you know that choosing the right material for your CNC machining prototype is a make-or-break decision. The material you select affects everything from (machining difficulty) and prototype performance to cost and lead time. But with so many options available, how do you know which material meets your project’s specific needs? In this guide, we’ll break down the key material requirements for CNC machining prototypes, helping you make informed choices that align with your product’s 功能 (functionality), 外观 (appearance), and performance goals.

Understanding CNC Machining Prototype Materials

Before diving into specific requirements, let’s clarify why material selection matters so much for CNC prototypes. Unlike mass production, where materials are often chosen primarily for cost and scalability, prototype materials need to balance multiple factors: they must be easy to machine (to keep development timelines short), accurately represent the final product’s properties (for reliable testing), and sometimes mimic the look and feel of production materials (for stakeholder presentations).

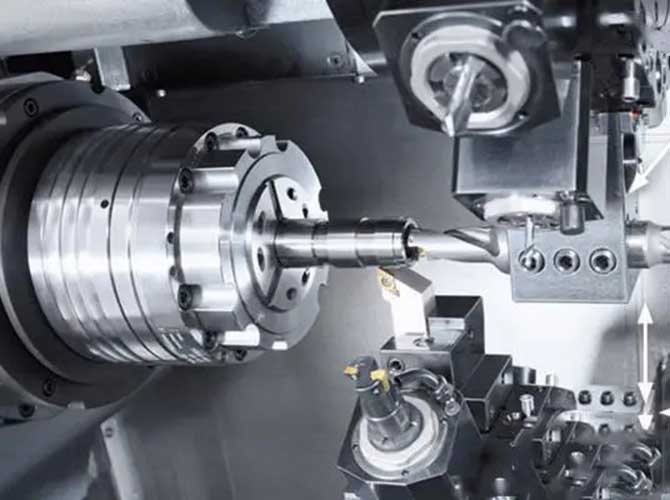

CNC machining—a subtractive manufacturing process that removes material from a solid block—works with a wide range of materials, but not all materials are equally suitable for every application. The key is to match the material’s characteristics to your prototype’s intended use, whether that’s validating a design concept, testing structural integrity, or demonstrating a final product’s appearance.

Material Requirements for Common Prototype Types

Different products have different needs, and your prototype material should reflect that. Let’s explore the material requirements for the most common types of CNC machined prototypes.

1. Conventional Product Prototypes: Balancing Ease and Aesthetics

For most standard prototypes—especially those in the early stages of development—ABS (Acrylonitrile Butadiene Styrene) is the go-to material. Here’s why it meets the core requirements for conventional prototypes:

- Machinability: ABS is relatively soft (Shore D hardness of 60-70) and machines cleanly, producing smooth edges without excessive tool wear. This makes it fast to process, reducing prototype turnaround time.

- Finish quality: After machining, ABS can achieve a high-quality surface finish that polishes well, making it ideal for visual prototypes.

- Cost-effectiveness: ABS is affordable compared to engineering-grade plastics, making it perfect for iterative prototyping where multiple versions may be needed.

- Versatility: It’s available in a wide range of colors, eliminating the need for immediate painting or finishing if basic color representation is sufficient.

A study by the Prototype Manufacturers Association found that ABS is used for approximately 65% of initial concept prototypes, thanks to its balanced performance across these key areas.

2. High-Temperature Resistant Prototypes: Withstanding Heat Challenges

When your product needs to perform in high-temperature environments—think engine components, industrial machinery, or kitchen appliances—your prototype material must withstand elevated temperatures without deforming or losing strength. The top material choices and their requirements are:

| Material | Temperature Resistance | Machinability | Bondability | Key Applications |

| Epoxy Resin | Up to 150°C (302°F) | Good | No | Electrical insulators, heat shields |

| Bakelite | Up to 180°C (356°F) | Fair | No | Electrical components, handles |

| Black PC | Up to 120°C (248°F) | Good | Yes | Heat-resistant enclosures |

| PA (Nylon) | Up to 100-150°C (212-302°F) | Good | No | High-temperature gears, bushings |

A critical requirement for three of these materials (epoxy resin, Bakelite, and PA) is their inability to be effectively bonded. This means prototypes made from these materials must be machined as a single piece, which affects design considerations:

- Design for monolithic construction: Avoid complex geometries that would require assembly, as glued joints will fail under heat stress.

- Tool path optimization: Plan machining paths to minimize material waste since you can’t combine smaller pieces.

- Thickness considerations: Ensure sufficient wall thickness for structural integrity at high temperatures.

Black PC stands out as the only heat-resistant option that can be bonded, offering more design flexibility for complex assemblies that need moderate temperature resistance.

3. Wear-Resistant Prototypes: Materials for Durability Testing

Products that experience friction or repeated contact—like gears, bearings, or sliding mechanisms—require prototypes made from wear-resistant materials to accurately test durability. The primary options are:

- POM (Polyoxymethylene / Acetal): Known for its low friction coefficient and excellent wear resistance, POM is ideal for moving parts. It has a smooth surface finish that reduces friction-induced wear during testing.

- PA (Nylon): Especially when reinforced with fibers, nylon offers good abrasion resistance and can handle moderate loads, making it suitable for prototypes that need to simulate long-term wear.

Both materials share a key requirement: they cannot be reliably bonded. This means:

- Overall machining requirement: The prototype must be machined from a single block, which may require larger material stock.

- Design simplicity: Avoid undercuts or internal features that would make single-piece machining difficult.

- Tolerance control: These materials can have slight dimensional changes due to moisture absorption, so machining tolerances should account for this characteristic.

4. High-Toughness Prototypes: Materials for Impact Resistance

Prototypes that need to demonstrate impact resistance, flexibility, or durability under stress—such as sports equipment, protective cases, or automotive components—require materials with high toughness. The top choices are:

- PA (Nylon): Offers excellent toughness and impact resistance, especially in cold temperatures, making it suitable for prototypes tested in varying environments.

- PP (Polypropylene): Known for its flexibility, chemical resistance, and ability to withstand repeated bending without breaking.

Like their wear-resistant counterparts, these materials cannot be effectively bonded, necessitating overall processing. This creates specific requirements:

- Material selection based on flexibility needs: PP offers greater flexibility than PA, while PA provides better impact strength at lower temperatures.

- Machining considerations for flexible materials: Both materials can “spring back” slightly after machining, so tool paths and cutting parameters must be adjusted to achieve precise dimensions.

- Testing alignment: The prototype material’s toughness should match the final production material as closely as possible to ensure accurate impact test results.

5. Transparent Prototypes: Materials for Optical Clarity

When your product relies on transparency—such as lenses, display covers, or light fixtures—your prototype must accurately replicate optical properties. The primary transparent materials for CNC machining prototypes are:

- PMMA (Acrylic): Offers excellent optical clarity (92% light transmission) and is easier to machine than glass, making it ideal for visual prototypes.

- Transparent ABS: Provides better impact resistance than PMMA but with slightly lower clarity (85-90% light transmission).

- Transparent PC (Polycarbonate): Combines good clarity (89% light transmission) with high impact resistance, suitable for prototypes needing both transparency and durability.

The key requirement for these materials is the need for post-machining polishing to achieve the desired optical effect:

- Surface finish preparation: Machining marks must be carefully polished out, with progressive grits from 400 to 2000 to achieve a glass-like finish.

- Machining parameters: Use sharp tools and slower feed rates to minimize surface scratches that would require extra polishing time.

- Handling precautions: These materials are prone to scratching, so cleanroom conditions and soft handling tools are recommended during processing.

Surface Treatment Requirements for CNC Prototypes

Even the best material choices can fall short if surface treatments aren’t properly considered. The right surface finish not only enhances appearance but can also improve functionality, such as increasing wear resistance or reducing friction. Common surface treatment requirements include:

1. Spraying (Painting) Options

Prototype spraying offers versatile finish options to match production intent:

- Glossy finish: Provides a high-shine surface that highlights design details and mimics injection-molded parts. Requires careful surface preparation to avoid orange peel texture.

- Matte finish: Reduces glare and hides minor surface imperfections, ideal for functional prototypes where appearance is secondary to testing.

- Sandy texture: Creates a tactile surface with improved grip, suitable for handles or control surfaces.

- Transparent/translucent coatings: Enhance or protect the natural material color while adding a protective layer.

- Fluorescent coatings: Useful for prototypes that need high visibility, such as safety equipment.

- Rubber oil finish: Provides a soft, rubber-like feel, often used for consumer electronics and handheld devices.

2. Other Surface Treatments

- Electroplating: Adds a metallic layer (chrome, nickel, gold) for decorative purposes or to improve conductivity, requiring precise surface preparation to ensure adhesion.

- Frosting: Creates a matte, non-reflective surface on transparent materials, often used for light diffusers or privacy components.

- Silk screening and pad printing: Apply text, logos, or graphics, requiring clean, oil-free surfaces for proper ink adhesion.

Each surface treatment has specific material compatibility requirements. For example, some plastics require a primer before painting, while electroplating works best with materials that can conduct electricity (or have been treated to do so).

The Role of Material Selection in Prototype Success

Choosing the right material isn’t just about meeting technical requirements—it directly impacts your product development timeline and cost efficiency. Here’s why material selection matters:

- Risk reduction: Using appropriate prototype materials helps identify design flaws early, avoiding costly mold modifications later. For example, testing a heat-resistant prototype with the wrong material might miss potential deformation issues that only appear at high temperatures.

- Development speed: Materials that machine quickly and require minimal post-processing can shorten iteration cycles, getting your product to market faster.

- Stakeholder confidence: Prototypes that accurately represent the final product’s appearance and performance are more likely to gain approval from investors, designers, and end-users.

Industry data supports this: A survey of product development teams found that projects using application-matched prototype materials reduced time-to-market by an average of 22% compared to those using generic materials.

Yigu Technology’s Perspective

At Yigu Technology, we believe material selection is the cornerstone of effective CNC prototype machining. By matching materials to functional requirements—whether heat resistance, transparency, or toughness—we help clients validate designs with confidence. Our 98.5% yield rate reflects our commitment to material expertise, ensuring prototypes accurately predict production performance while accelerating development cycles.

Frequently Asked Questions (FAQ)

- Can I use production materials for CNC prototypes?

Yes, but production materials may be more expensive or harder to machine. For early prototypes, cost-effective alternatives like ABS often suffice, with production materials introduced for final validation.

- How do bonding limitations affect prototype design?

Materials that can’t be bonded require monolithic machining, which may limit design complexity. However, skilled CNC programmers can still achieve intricate geometries through advanced tool paths.

- Do surface treatments affect prototype performance testing?

They can. For functional testing, consider if coatings or finishes will alter properties like friction, heat resistance, or flexibility. Test uncoated prototypes alongside finished ones for comparison.