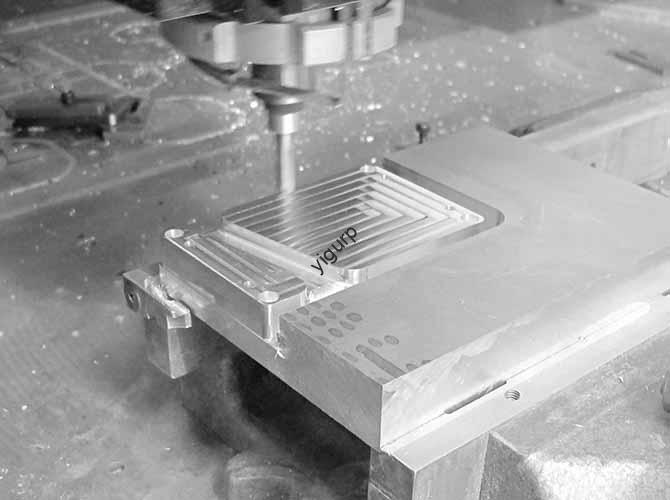

The step problem of CNC machining plane—visible, uneven ridges at tool joints or surface transitions—undermines part precision, surface quality, and even functionality (e.g., sealing performance for flat components). This issue stems from multiple interrelated factors, from tool wear to programming gaps. This article systematically breaks down root causes, targeted solutions, and preventive measures to help you eliminate plane steps effectively.

1. Root Causes & Solutions: Tool-Related Factors

Tools are the direct “contact point” between the machine and workpiece—any tool defect or mismanagement often leads to steps. Below is a causal chain analysis of common tool issues and their fixes:

| Tool Issue | Manifestation | Solution | Advanced Optimization |

| Tool Wear/Damage | Localized wear or chipping on the cutting edge creates uneven material removal, forming steps at tool paths. | Replace worn tools immediately; for indexable inserts, inspect edge integrity every 200–300 machining cycles. | Use diamond-coated blades or polycrystalline diamond (PCD) tools—improves wear resistance by 3–5x, reducing cumulative error from tool loss. |

| Inconsistent Tool Diameter | After tool changes, diameter differences between old and new tools cause depth deviations (e.g., a 0.02 mm diameter gap leads to 0.01 mm step height). | Implement unified tool management: Label tools by diameter (e.g., “φ10.00 mm End Mill #3”) and calibrate new tools before use. | Use a tool presetter to measure diameter and length with ±0.001 mm accuracy; store data in the CNC system for automatic compensation. |

| Tool Installation Errors | Loose collets or aluminum slag in the spindle taper hole cause tool deflection (≥0.03 mm) or misalignment, leading to uneven cutting. | Clean spindle taper holes and collet contact surfaces with alcohol; reinstall tools and torque collets to manufacturer specs (e.g., 25 N·m for ER32 collets). | Replace standard collets with hydraulic or shrink-fit collets—reduces runout to <0.005 mm, ensuring stable tool positioning. |

2. Equipment & Parameter Optimization to Eliminate Steps

Machine rigidity and cutting parameters directly affect surface smoothness. Use this contrast 式 structure to identify suboptimal setups and correct them:

2.1 Machine Tool Mechanical Condition Checks

Poor machine maintenance often leads to periodic or random steps. Focus on these critical components:

| Component | Problem Symptom | Maintenance Solution |

| Ball Screw Thrust Bearings | Wear causes motion lag (≥0.01 mm) or jitter, forming regular steps every 10–20 mm. | Lubricate lead screws with lithium-based grease every 50 operating hours; replace bearings if backlash exceeds 0.005 mm. |

| Guide Rails | Contamination or wear increases friction, leading to uneven feed rates and irregular steps. | Clean guide rails daily with a lint-free cloth; check for rail scratches—repair with precision grinding if damage is found. |

| Spindle | Spindle runout (>0.005 mm) causes tool vibration, creating wavy steps on large planes. | Perform spindle dynamic balancing quarterly; replace spindle bearings if runout exceeds tolerance. |

2.2 Cutting Parameter Adjustment

Aggressive parameters (fast feed, deep cuts) trigger vibration and built-up edges—indirect causes of steps. Follow these linear guidelines:

- Reduce Cutting Depth: For finishing, limit depth of cut (ap) to 0.1–0.3 mm (vs. 0.5–1 mm for roughing). Shallow cuts minimize tool deflection and heat buildup.

- Optimize Feed Rate: Lower feed rate (F) to 0.05–0.1 mm/rev for finishing (e.g., from 0.15 mm/rev). Slow feeds reduce chip load and built-up edges.

- Increase Cutting Speed: For aluminum alloys, raise speed (Vc) to 300–500 m/min; for steel, 100–200 m/min. Higher speeds break up built-up edges and improve surface finish.

- Layered Machining: For thick workpieces (≥10 mm), split finishing into 2–3 passes (e.g., 0.2 mm → 0.1 mm → 0.05 mm depth). Each pass corrects minor unevenness from the previous one.

3. Programming & Path Planning Improvements

Even with good tools and machines, poor path design creates step gaps. Use this 总分结构 to optimize programming:

3.1 Tool Path Connection Design

The key is to eliminate gaps between adjacent tool paths. Apply these techniques:

- Add Overlap: Design a 0.1–0.2 mm overlap between parallel tool paths (e.g., for a 10 mm wide end mill, set path spacing to 9.8 mm). This covers any residual material from the previous pass.

- Use Transition Arcs: Replace sharp corners in tool paths with small arcs (R0.5–1 mm) when changing directions. Arcs prevent sudden tool deceleration/acceleration, which causes micro-steps.

- Large Disc Tools for Large Planes: Prioritize face mills (e.g., φ50 mm, 8 teeth) over small end mills for planes >200 mm². Face mills cover more area per pass, reducing the number of tool joints (and step opportunities) by 50–70%.

3.2 Margin Allocation Strategy

Insufficient finishing allowance leaves roughing tool marks (steps) unremoved. Follow this rule:

- For aluminum alloys: Allocate 0.3–0.5 mm total allowance (0.2–0.3 mm roughing, 0.1–0.2 mm finishing).

- For steel: Allocate 0.5–0.8 mm total allowance (0.3–0.5 mm roughing, 0.2–0.3 mm finishing).

- Example: A 20 mm thick steel plate—rough to 20.3 mm, then finish to 20.0 mm. This ensures the finishing pass fully covers roughing marks.

4. Special Scenarios: Pseudo-Steps & Deep Cavity Steps

Some “steps” are not true dimensional gaps—they’re surface defects. Use this 设问 / 回答 structure to address unique cases:

4.1 How to Identify and Fix Pseudo-Steps?

Pseudo-steps are irregular deep lines caused by built-up edges (not tool misalignment), common in low-speed re-cutting (Vc <100 m/min for steel).

Solution:

- Switch to coated inserts (TiAlN or TiCN coating)—reduces built-up edges by 80% by lowering friction.

- Increase cutting speed by 30–50% (e.g., from 100 m/min to 150 m/min for 45# steel). Higher speeds break up chip adhesion on the tool edge.

4.2 How to Eliminate Deep Cavity/Bottom Steps?

Residual steps on deep cavity bottoms (depth >5x tool diameter) result from tool bar deflection or incomplete cutting.

Three-Step Fix:

- Add a Finishing Arc: After the last layer of deep milling, program a 0.5–1 mm radius arc to interpolate the bottom surface—smooths residual step marks.

- Two-Tool Processing: Use a roughing end mill (e.g., φ12 mm) to remove bulk material, then a shorter, stiffer finishing end mill (e.g., φ12 mm, 3x D length) to clean the bottom—reduces deflection.

- Tip Compensation Calibration: Calculate tool bar deflection (e.g., a φ10 mm, 50 mm long bar deflects ~0.02 mm under 50 N load) and add a negative Z-compensation value (e.g., -0.02 mm) to ensure full cutting.

5. Preventive Quality Control Measures

Proactive monitoring prevents steps before they occur. Use this list of actionable practices:

- Real-Time Monitoring: Install vibration sensors on the spindle and workpiece—set alerts for vibration >0.01 mm (triggers automatic feed rate reduction).

- Tool Life Management: Set maximum tool life limits (e.g., 500 parts for aluminum, 300 parts for steel) and replace tools proactively—avoids wear-induced steps.

- Cutting Fluid Maintenance: Filter cutting fluid daily to remove chips (>50 μm); replace fluid every 3 months. Clean fluid prevents chip accumulation on the workpiece, which causes uneven cutting.

Yigu Technology’s Perspective

At Yigu Technology, we solve the step problem of CNC machining plane by combining technical precision and proactive management. For large-plane parts (e.g., automotive chassis components), we use shrink-fit collets and φ63 mm face mills—reducing tool runout to <0.003 mm and step frequency by 80%. For deep cavities, our two-tool strategy (roughing + short finishing end mills) eliminates bottom steps in 95% of cases. We also train operators on real-time vibration monitoring: our clients report a 60% drop in step-related rework after adopting this system. Ultimately, solving plane steps isn’t just about fixing issues—it’s about building a stable, repeatable process that avoids them entirely.

FAQ

- What’s the maximum step height that can be corrected with re-machining?

For small steps (<0.05 mm), a single finishing pass (ap=0.03–0.05 mm, F=0.05 mm/rev) can smooth the surface. Steps >0.1 mm require two passes: first a light roughing pass (ap=0.08 mm) to reduce the step, then a finishing pass—this avoids overloading the tool.

- Can software (CAM) help prevent step problems?

Yes. Advanced CAM software (e.g., UG/NX, Mastercam) offers “constant chip load” and “smooth path” features. Constant chip load maintains consistent cutting forces (avoids vibration), while smooth paths add transition arcs automatically—reducing step risk by 40–50%.

- Why do steps still appear even with new tools and calibrated parameters?

Check for workpiece clamping errors: Loose clamps cause workpiece movement (≥0.02 mm) during machining. Use toggle clamps or vacuum chucks with ≥80 kPa pressure to secure parts. Also, ensure the workpiece is flat—warped blanks (e.g., 0.1 mm bow in a 200 mm plate) lead to uneven cutting and steps.