If you’re exploring metal 3D printing for prototyping, production, or specialized projects, one of the first questions you’ll ask is: What’s the cost per gram? The answer depends on multiple factors—from material type to production volume—but this guide breaks down the key details to help you calculate and optimize expenses.

1. Cost Per Gram of Mainstream Metal 3D Printing Materials

The material is the most direct factor affecting the cost per gram of metal 3D printing. Below is a detailed comparison of common materials, their price ranges, and typical use cases:

| Material Type | Common Grades | Price Range (RMB/gram) | Key Features | Typical Applications |

| Stainless Steel | 304, 316L | 0.5 ~ 2 | Cost-effective, high mechanical strength | Industrial parts, tooling, consumer goods |

| Aluminum Alloy | AlSi10Mg | 1 ~ 3 | Lightweight, corrosion-resistant | Aerospace components, automotive parts |

| Titanium Alloy | Ti6Al4V | 5 ~ 15 | Ultra-light, high strength, biocompatible | Medical implants, aerospace critical parts |

| Cobalt-Chromium Alloy | CoCr | 3 ~ 8 | High hardness, wear-resistant | Dental crowns, biomedical devices |

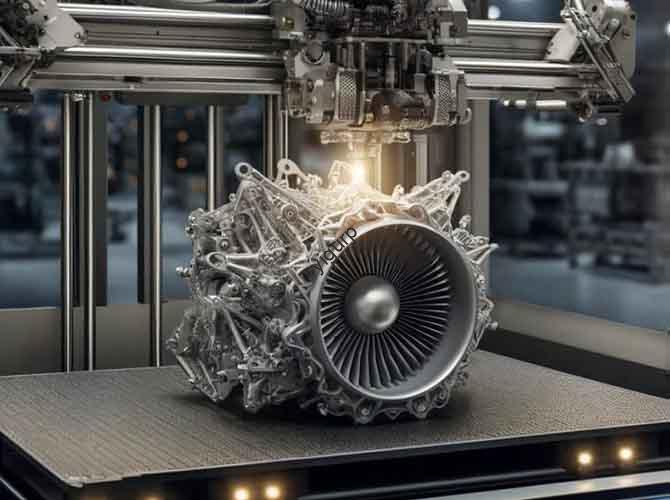

| Nickel-Based Alloy | Inconel 625 | 4 ~ 10 | High-temperature resistance, corrosion-resistant | Extreme environment parts (e.g., jet engines) |

2. 6 Key Factors That Impact Metal 3D Printing Cost Per Gram

While material cost sets the baseline, other factors can significantly raise or lower the final cost per gram. Let’s break them down with specific examples and comparisons:

(1) Material Quality & Rarity

Not all metal powders are the same. Purity, particle size, and production process of the powder directly affect the price:

- Standard stainless steel powder (316L) with 99.5% purity costs ~0.5–2 RMB/gram.

- Rare metals like hafnium or rhenium (used in advanced aerospace) can cost tens of RMB per gram due to limited supply and complex extraction.

(2) 3D Printing Process Type

Different processes have varying equipment, maintenance, and efficiency costs, which trickle down to the cost per gram:

| Process Name | Precision Level | Cost Level (vs. SLM) | Best For |

| Selective Laser Melting (SLM) | High | 100% (benchmark) | Small, high-precision parts (e.g., medical) |

| Electron Beam Melting (EBM) | Medium | 80–90% | Large or complex structures (e.g., aerospace) |

| Binder Jetting | Low-Medium | 50–60% | High-volume, low-cost parts (e.g., hardware) |

(3) Part Complexity

Complex geometries require more support materials and post-processing, increasing the effective cost per gram:

- A simple block-shaped part (no supports, minimal post-processing) may cost the same as the raw material price (e.g., 0.5–2 RMB/gram for stainless steel).

- A part with internal channels, thin walls (<1mm), or hollow designs can double the cost per gram—due to extra support material waste and 2–3x more post-processing time.

(4) Post-Processing Requirements

Metal 3D printed parts rarely come “ready-to-use.” Processes like support removal, sanding, and heat treatment add costs:

- For titanium alloy parts (Ti6Al4V), thermal stress relief (a necessary post-process for safety) can account for 20–30% of the total cost—raising the effective cost per gram from 5–15 RMB to 6–19.5 RMB.

- Simplified post-processing (e.g., skipping polishing for non-visible parts) can reduce costs by 10–15%.

(5) Order Volume

Batch size has a huge impact on cost per gram, as it spreads fixed costs (equipment setup, material waste) across more parts:

- Small batches (dozens of parts): Higher cost per gram—e.g., stainless steel parts may cost 1.5–2 RMB/gram (vs. 0.5–1 RMB/gram for large batches).

- Large batches (thousands of parts): 30–50% discount on cost per gram. For example, aluminum alloy (AlSi10Mg) drops from 2–3 RMB/gram to 1–1.8 RMB/gram.

(6) Supplier & Regional Differences

Domestic and international suppliers have significant price gaps:

- Domestic Chinese suppliers: Typically 30–50% cheaper than European or American suppliers. For example, titanium alloy (Ti6Al4V) costs 5–10 RMB/gram domestically vs. 10–15 RMB/gram overseas.

- Additional costs: International orders may include logistics (5–10% of total cost) and customs duties (3–8%), further increasing the effective cost per gram.

3. Real-World Cost Examples: 10cm³ Parts

To make the cost per gram more tangible, here’s how much a 10cm³ part (common for small components) costs with different materials:

| Material | Density (g/cm³) | Part Weight (g) | Cost Per Gram (RMB) | Total Part Cost (RMB) |

| Stainless Steel 304 | 7.9 | ~79 | 0.5 ~ 2 | 39.5 ~ 158 |

| Aluminum Alloy AlSi10Mg | 2.7 | ~27 | 1 ~ 3 | 27 ~ 81 |

| Titanium Alloy Ti6Al4V | 4.5 | ~45 | 5 ~ 15 | 225 ~ 675 |

| Cobalt-Chromium Alloy CoCr | 8.3 | ~83 | 3 ~ 8 | 249 ~ 664 |

4. 5 Practical Tips to Reduce Metal 3D Printing Cost Per Gram

If you want to lower expenses without sacrificing quality, try these strategies:

- Optimize part design: Remove unnecessary complex features (e.g., oversize internal channels) to cut support material use by 30–40%.

- Choose cost-effective materials: Replace high-cost metals with alternatives when possible—e.g., use stainless steel 316L instead of titanium alloy for non-biomedical, non-aerospace parts.

- Combine orders: Partner with other businesses to pool small orders into a large batch (thousands of parts) and get a 30–50% discount.

- Work with domestic suppliers: Avoid international shipping and duties by choosing local suppliers—saving 30–50% on total costs.

- Simplify post-processing: Skip non-essential steps (e.g., polishing for internal, non-visible surfaces) to reduce post-processing costs by 10–15%.

Yigu Technology’s Perspective on Metal 3D Printing Cost

At Yigu Technology, we’ve observed that material selection and order volume are the two most impactful levers for cost optimization in metal 3D printing. Many clients initially overspecify materials (e.g., using titanium for non-critical parts) or order small batches, leading to higher costs. Our team works with clients to match materials to actual performance needs—for example, recommending aluminum alloy AlSi10Mg for lightweight automotive parts instead of pricier options—and helps aggregate orders to unlock volume discounts. We also prioritize domestic supply chains, enabling clients to access high-quality metal 3D printing services at 30–40% lower costs than international providers. As the industry evolves, we expect binder jetting technology to drive further cost reductions, making metal 3D printing more accessible for mid-volume production.

FAQ

- Why is titanium alloy 3D printing so expensive per gram?

Titanium alloy (e.g., Ti6Al4V) is expensive because its powder requires high purity (99.8%+), complex production processes (e.g., gas atomization), and it is biocompatible and high-strength—making it ideal for high-end medical and aerospace applications where performance cannot be compromised.

- Can I get metal 3D printing for less than 1 RMB per gram?

Yes—stainless steel (304, 316L) is the most affordable option, with a cost per gram of 0.5–2 RMB. For large batches (thousands of parts) and simple designs, the effective cost can drop to 0.5–0.8 RMB per gram.

- How much does post-processing add to the cost per gram?

Post-processing typically adds 10–30% to the total cost. For example, titanium parts need thermal stress relief (20–30% of total cost), while stainless steel parts may only need basic support removal (5–10% of total cost). The more complex the post-processing, the higher the effective cost per gram.