If you’re planning to manufacture parts via CNC machining, the first question you’ll likely ask is: How much will it cost? The cost of CNC machining a part isn’t fixed—it depends on factors like material choice, machining time, and part complexity. This guide breaks down every key cost driver, provides real-world examples, and shares tips to optimize expenses.

1. 7 Core Factors That Determine the Cost of CNC Machining a Part

The total cost of a CNC-machined part is a sum of multiple components. Below is a detailed breakdown of each factor, with specific numbers and comparisons to help you estimate:

(1) Material Cost

Material cost is calculated based on the weight or volume of the part. Different materials have huge price differences, directly impacting the base cost. Here’s a reference for common metal materials:

| Material Type | Price Range (RMB/kg) | Key Characteristics | Typical Use Cases |

| Carbon Steel | 30 ~ 80 | Low cost, high strength | Structural parts, brackets |

| Aluminum Alloy | 50 ~ 100 | Lightweight, corrosion-resistant | Automotive components, electronic enclosures |

| Stainless Steel | 100 ~ 200 | Rust-resistant, durable | Food machinery parts, medical tools |

| Copper | 100 ~ 200 | Excellent electrical conductivity | Electrical connectors, heat sinks |

Example: A 0.5kg aluminum alloy part has a material cost of 25–50 RMB (50–100 RMB/kg × 0.5kg).

(2) Machining Time Cost

Machining time is the most critical factor in CNC cost, as equipment and labor are charged hourly. It includes three parts:

- Programming time: 0.5–2 hours for simple parts (e.g., a basic block); over 5 hours for complex parts (e.g., parts with curved surfaces or tight tolerances).

- Actual machining time: Depends on part size, cutting speed, and tool path. A small aluminum part may take 1–2 hours, while a large stainless steel part could take 5–10 hours.

- Clamping & tool change time: 0.2–1 hour per part; multiple clampings (e.g., for multi-sided machining) can double this time.

Equipment is typically charged hourly, with prices varying by type:

- Ordinary CNC machines: 50–100 RMB/hour

- High-end CNC machines (e.g., 5-axis linkage): 100–300 RMB/hour

(3) Equipment Depreciation & Maintenance

CNC machines are expensive (tens of thousands to millions of RMB), so depreciation costs are included in quotes (usually spread over 5–10 years). Additionally, maintenance costs—such as tool wear (10–50 RMB per tool change) and lubricating oil (50–200 RMB per month)—add 5–15% to the total cost.

(4) Labor Cost

Labor cost covers operators, programmers, and quality inspectors, charged at 50–100 RMB/hour (varies by region and skill level). For a part that takes 3 hours to machine, labor cost ranges from 150–300 RMB.

(5) Post-Processing Cost

Most CNC parts need post-processing to meet functional or aesthetic needs. Common processes and their costs:

| Post-Processing Type | Cost Range (RMB per part) | Purpose |

| Surface Treatment | 50 ~ 200 | Anodizing (anti-corrosion), electroplating (wear resistance) |

| Heat Treatment | 100 ~ 500 | Quenching (hardening), tempering (reducing brittleness) |

| Secondary Processing | 50 ~ 200 | Drilling, tapping, or grinding (refining precision) |

(6) Part Complexity & Precision

Complexity and precision directly increase machining time and skill requirements:

- Simple parts (e.g., block structures with no curved surfaces): Lower cost—50–100 RMB per part.

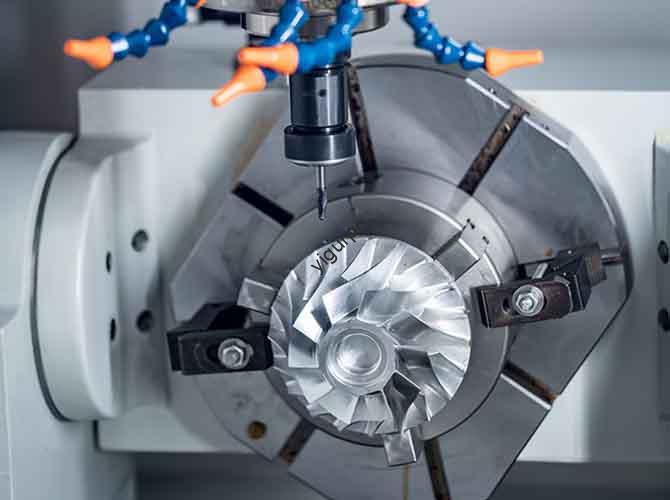

- Complex parts (e.g., thin walls <2mm, curved surfaces, or tolerances ±0.01mm): Higher cost—200–1,000 RMB per part. For example, a high-precision stainless steel part with tight tolerances can cost 3x more than a simple aluminum part of the same size.

(7) Order Volume

Batch processing unlocks discounts, as fixed costs (e.g., programming, setup) are spread across more parts. Here’s how volume affects unit cost:

| Order Volume | Unit Cost (Example for a Simple Aluminum Part) | Discount Rate |

| 1–10 pieces | 100 RMB/piece | 0% (no discount) |

| 11–50 pieces | 80 RMB/piece | 20% |

| 51–100 pieces | 70 RMB/piece | 30% |

| 100+ pieces | 60 RMB/piece | 40% |

2. Typical Cost Ranges for CNC-Machined Parts

To make cost estimates more concrete, here’s a breakdown of typical prices based on part complexity:

| Part Complexity Level | Precision Requirement | Cost Range (RMB per part) | Examples |

| Low | Low (tolerances ±0.1mm) | 10 ~ 50 | Simple aluminum brackets, basic spacers |

| Medium | Ordinary (±0.05mm) | 50 ~ 200 | Stainless steel gears, aluminum enclosures |

| High | High (±0.01mm) | 200 ~ 1,000+ | Precision medical parts, aerospace components |

Real-World Examples:

- A simple 0.5kg aluminum part (low complexity): 50–100 RMB

- A complex 1kg stainless steel part (high precision): 500–1,000 RMB

3. 2 Practical Methods to Estimate CNC Machining Costs

You can calculate the cost of a CNC part using two common formulas. Below are step-by-step examples for each:

Method 1: Calculate by Machining Time

Formula: Total Cost = (Equipment Hourly Fee + Labor Hourly Fee) × Machining Time + Material Cost + Post-Processing Cost

Example:

- Equipment hourly fee: 100 RMB/hour (ordinary CNC machine)

- Labor hourly fee: 50 RMB/hour

- Machining time: 3 hours (programming: 1 hour + actual machining: 2 hours)

- Material cost: 50 RMB (1kg carbon steel × 50 RMB/kg)

- Post-processing cost: 100 RMB (anodizing)

Total Cost = (100 + 50) × 3 + 50 + 100 = 150 × 3 + 150 = 450 + 150 = 600 RMB

Method 2: Calculate by Material Weight/Volume

Formula: Total Cost = (Material Unit Price × Part Weight) + Machining Fee + Post-Processing Cost

Example:

- Material unit price: 80 RMB/kg (aluminum alloy)

- Part weight: 0.5kg → Material cost: 80 × 0.5 = 40 RMB

- Machining fee: 300 RMB (includes equipment, labor, and depreciation)

- Post-processing cost: 50 RMB (drilling)

Total Cost = 40 + 300 + 50 = 390 RMB

4. 5 Proven Tips to Reduce CNC Machining Costs

You don’t have to compromise on quality to lower costs. Try these strategies:

- Optimize part design: Reduce material use (e.g., add hollow structures for lightweighting) and simplify geometry (e.g., replace curved surfaces with straight lines) to cut material and machining time costs by 10–30%.

- Increase order volume: Batch orders of 50+ pieces can lower unit costs by 20–40% (as shown in the Order Volume table above).

- Choose cost-effective materials: Use aluminum alloy instead of stainless steel for non-rust-resistant parts, or carbon steel instead of copper for non-conductive parts—saving 20–50% on material costs.

- Minimize post-processing: Avoid unnecessary steps (e.g., skip polishing for internal, non-visible surfaces) to reduce post-processing costs by 10–25%.

- Negotiate with suppliers: Clarify precision requirements (e.g., use ±0.05mm tolerance instead of ±0.01mm if possible) to avoid overpaying for unneeded accuracy.

Yigu Technology’s Perspective on CNC Machining Costs

At Yigu Technology, we’ve found that design optimization and order volume are the most underutilized cost-saving tools for CNC machining. Many clients initially submit overcomplex designs (e.g., unnecessary thin walls) or small orders, leading to higher costs. Our team works with clients to simplify designs—for example, replacing multi-clamping setups with single-step machining—to cut time by 15–25%. We also help aggregate small orders into batches (e.g., combining 5 clients’ 10-piece orders into a 50-piece batch) to unlock 20–30% discounts. Additionally, we recommend material substitutions based on actual needs (e.g., aluminum alloy for non-heavy-duty parts) to reduce material costs without sacrificing performance. For most clients, these steps lower total costs by 20–40%.

FAQ

- Why does a 5-axis CNC machine cost more per hour than an ordinary CNC machine?

5-axis CNC machines offer higher precision and can machine complex parts in one setup (vs. multiple setups for ordinary machines). They require more advanced technology, higher maintenance costs, and skilled operators—all of which contribute to the higher hourly fee (100–300 RMB/hour vs. 50–100 RMB/hour).

- How much does post-processing add to the total cost of a CNC part?

Post-processing typically adds 10–30% to the total cost. For example, a 200 RMB aluminum part with anodizing (50–200 RMB) will have a total cost of 250–400 RMB—with post-processing accounting for 20–50% of the additional cost. Heat treatment (100–500 RMB) can add even more for high-strength parts.

- Can I get a fixed quote for CNC machining a part?

Yes—for simple, standardized parts (e.g., spacers, brackets), most suppliers will provide a fixed quote that includes all costs (material, machining, post-processing). For complex parts, suppliers may need a 3D model or technical drawing to calculate machining time and provide an accurate fixed quote.