If you’re getting into 3D printing, one of the first questions you’ll ask is, “Which 3D modeling software should I use?” The right software can make all the difference in creating successful 3D prints, whether you’re designing prototypes, functional parts, or creative projects. With so many options available, choosing the right tool for your needs can feel overwhelming. In this guide, we’ll explore the four most commonly used 3D printing modeling software options: SketchUp, SolidWorks, Pro/E (Creo), and UG (NX). We’ll break down their features, strengths, weaknesses, and ideal use cases to help you make an informed decision.

Understanding 3D Printing Modeling Software: Why It Matters

Before diving into specific software options, let’s clarify why choosing the right 3D modeling software is crucial for 3D printing success. 3D printing modeling software is where your digital designs take shape—literally. These programs allow you to create precise 3D models that can then be sliced into layers and printed by your 3D printer.

The software you choose impacts several key aspects of your 3D printing workflow:

- Design Accuracy: Critical for functional parts and prototypes that need to fit together

- Complexity Handling: Some software excels at simple shapes, while others handle intricate geometries

- Workflow Efficiency: User interface and tools determine how quickly you can turn ideas into models

- File Compatibility: Ensuring your designs can be exported in formats your 3D printer understands (like STL or OBJ)

- Feature Access: Advanced tools for structural analysis, material simulation, or organic modeling

Whether you’re a hobbyist printing figurines, an engineer creating prototypes, or a designer developing products, the right software will streamline your process and improve your results.

1. SketchUp: The User-Friendly “Digital Pencil”

SketchUp has earned its reputation as one of the most accessible 3D modeling tools on the market. Often described as the “pencil of electronic design,” it’s beloved for its intuitive approach to 3D creation.

Core Features of SketchUp

What makes SketchUp stand out is its simplicity without sacrificing functionality:

- Intuitive Interface: Designed to feel like drawing with pencil and paper, making it easy for beginners to learn

- Smart Drawing Tools: Automatically recognizes lines and surfaces, with built-in snapping that “captures” lines to create clean geometry

- Streamlined Workflow: Follows a straightforward process of drawing 2D lines, converting them to surfaces, then extruding to create 3D shapes

- Extensive Library: Thousands of pre-made 3D models in the 3D Warehouse to jumpstart your designs

- Flexible Export Options: Supports STL, OBJ, and other formats essential for 3D printing

Ideal Use Cases for 3D Printing

SketchUp shines in specific 3D printing applications:

- Architectural Models: Its surface-based modeling approach is perfect for buildings, rooms, and spatial designs

- Conceptual Prototypes: Quickly turning ideas into basic 3D forms for initial printing and testing

- Decorative Items: Creating sculptures, wall art, and decorative objects

- Beginner Projects: Great for learning the basics of 3D modeling before moving to more complex software

- Educational Use: Simple enough for students to grasp while still producing printable models

Strengths and Limitations

Like any software, SketchUp has distinct advantages and drawbacks:

Strengths:

- Extremely user-friendly, with a gentle learning curve

- Fast for creating simple to moderately complex shapes

- Affordable pricing, including a free web-based version

- Excellent for visualizing concepts quickly

Limitations:

- Less precise than engineering-focused software for functional parts

- Not ideal for highly complex geometries or organic shapes

- Limited advanced features for structural analysis

- May require plugins for optimal 3D printing preparation

Who Should Choose SketchUp?

SketchUp is perfect for beginners, hobbyists, architects, and designers who prioritize speed and ease of use over advanced engineering features. If you’re new to 3D modeling and want to start printing basic to moderately complex objects without investing weeks in learning software, SketchUp is an excellent choice.

2. SolidWorks: The Engineering Powerhouse

SolidWorks has established itself as a leading 3D CAD solution, particularly in engineering and manufacturing environments. Its combination of power and usability makes it a favorite among professionals creating 3D printable parts.

Core Features of SolidWorks

SolidWorks stands out for its robust toolset designed for engineering applications:

- Parametric Modeling: Changes to one part of the design automatically update related features, crucial for iterative design

- Comprehensive Tool Library: Extensive features for creating complex geometries, assemblies, and simulations

- Integrated Simulation Tools: Allows testing of part strength, stress points, and performance before printing

- Design Validation: Built-in checks to reduce errors and ensure manufacturability (including 3D printability)

- Advanced Assembly Features: Tools for creating and testing multi-part designs that fit together precisely

The Three Hallmarks of SolidWorks

As mentioned in our reference material, SolidWorks is defined by three key characteristics that benefit 3D printing users:

- Powerful Functionality: Handles everything from simple parts to complex assemblies with ease, ensuring your 3D prints will have the required precision.

- Easy to Learn and Use: Despite its power, SolidWorks features an intuitive interface that makes it accessible to users with basic CAD knowledge, reducing the learning curve for 3D printing applications.

- Technological Innovation: Regular updates keep it at the forefront of CAD technology, with specific features optimized for additive manufacturing workflows.

Ideal Use Cases for 3D Printing

SolidWorks excels in producing functional 3D prints:

- Mechanical Parts: Gears, brackets, enclosures, and moving components

- Functional Prototypes: Testing form, fit, and function before mass production

- Engineering Components: Parts requiring precise dimensions and tolerances

- Multi-Part Assemblies: Designs where multiple printed parts must work together

- Product Development: From concept models to pre-production samples

Strengths and Limitations

Strengths:

- Industry-leading parametric modeling for precise, editable designs

- Excellent for creating 3D printable parts with accurate dimensions

- Built-in tools to check for 3D printability issues

- Seamless integration with 3D printing slicers and workflows

- Strong community support and extensive learning resources

Limitations:

- More expensive than entry-level software

- Steeper learning curve than SketchUp for complete beginners

- Overkill for simple decorative prints

- Requires more powerful hardware to run smoothly

Who Should Choose SolidWorks?

SolidWorks is ideal for engineers, product developers, and serious makers who need to create functional, precise 3D prints. If your 3D printing projects involve mechanical parts, assemblies, or prototypes that need to perform specific functions, SolidWorks provides the tools to ensure your prints will work as intended.

3. Pro/E (Creo): The Parametric Pioneer

Pro/E, now known as Creo after rebranding, holds an important place in 3D modeling history as one of the first parametric CAD programs. Its modular approach makes it highly customizable for specific 3D printing needs.

Core Features of Pro/E/Creo

Pro/E stands out for its parametric precision and flexibility:

- Parametric Technology: As the earliest application of parametric modeling, it offers exceptional control over design parameters, ensuring consistent 3D prints

- Modular Structure: Users can select specific modules needed for their workflow, reducing complexity

- Integrated AD/CAM/CAE: Combines design, manufacturing, and engineering analysis in one platform

- Advanced Surface Modeling: Creates complex curved surfaces ideal for aesthetic 3D prints

- Scalable Functionality: Grows with your needs, from basic modeling to advanced simulations

Key Modules for 3D Printing

Pro/E’s modular design includes several components particularly useful for 3D printing:

- Sketching Module: Creates the 2D foundations for 3D models with precise dimensions

- Parts Production: Core module for building 3D geometries ready for printing

- Assembly Design: For creating multi-part designs where printed components must fit together

- Sheet Metal Design: Specialized tools for creating 3D printable sheet metal-like structures

- Processing Simulation: Analyzes how designs will perform during 3D printing

Ideal Use Cases for 3D Printing

Pro/E is well-suited for:

- Complex Geometries: Intricate designs that require precise parametric control

- Aesthetic Prototypes: Products where appearance matters alongside functionality

- Custom Parts: Unique components tailored to specific applications

- Engineering Validation: Testing designs before investing in production

- Industry-Specific Parts: Particularly strong for aerospace, automotive, and industrial applications

Strengths and Limitations

Strengths:

- Robust parametric modeling for highly accurate 3D printable designs

- Customizable workflow through modular components

- Excellent for both simple and complex 3D printing projects

- Strong surface modeling for aesthetic prints

- Industry-proven reliability in manufacturing environments

Limitations:

- Interface can feel dated compared to newer software

- Steeper learning curve for parametric concepts

- Higher price point than basic modeling software

- Some advanced features require additional modules

Who Should Choose Pro/E/Creo?

Pro/E (Creo) is best for professionals in manufacturing, aerospace, and automotive industries who need precise control over their 3D printed parts. If you value parametric flexibility and plan to create both prototypes and production-ready 3D prints, Pro/E offers the depth and reliability needed for complex projects.

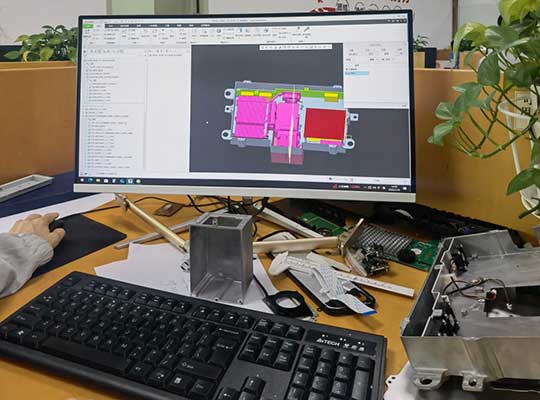

4. UG (NX): The Mold and Manufacturing Expert

UG, now officially called Siemens NX, is a powerful CAD/CAM system with particular strengths in mold design and manufacturing—making it highly valuable for 3D printing applications, especially in industrial settings.

Core Features of UG/NX

UG stands out for its manufacturing-focused capabilities:

- Advanced Solid Modeling: Creates complex 3D geometries with precision

- Integrated CAD/CAM Functionality: Seamlessly connects design with manufacturing processes, including 3D printing

- Mold Design Specialization: Industry-leading tools for creating molds, which translates well to complex 3D prints

- Freeform Modeling: Combines parametric control with flexible shape creation

- Simulation Tools: Analyzes how designs will perform during printing and in use

Evolution and Accessibility

As noted in our reference material, UG has evolved significantly:

- Initially developed for high-end workstations, it’s now fully optimized for PC use

- Growing popularity among individual users and small businesses

- Expanded compatibility with consumer and professional 3D printers

- Regular updates have improved its 3D printing workflows and file compatibility

Ideal Use Cases for 3D Printing

UG excels in industrial 3D printing applications:

- Mold Prototypes: 3D printed mold inserts and tooling components

- Industrial Parts: Complex components for machinery and equipment

- High-Precision Prints: Parts requiring tight tolerances and fine details

- Production Aids: 3D printed jigs, fixtures, and manufacturing tools

- Functional Testing: Durable prototypes that mimic production parts

Strengths and Limitations

Strengths:

- Exceptional for creating complex 3D printable geometries

- Strong integration with manufacturing processes, including 3D printing

- Industry-leading tools for mold-related 3D prints

- Robust simulation capabilities for print success prediction

- Excellent for both rapid prototyping and production parts

Limitations:

- Most complex interface among the four options

- Highest learning curve, particularly for beginners

- Premium pricing model aimed at professional users

- Overly complex for simple 3D printing projects

Who Should Choose UG/NX?

UG is ideal for manufacturing professionals, mold designers, and industrial engineers who need to create complex 3D prints for production environments. If your work involves creating 3D printed tooling, molds, or industrial components, UG provides the specialized tools needed for these advanced applications.

Comparing the Four Leading 3D Printing Modeling Software Options

To help you choose the right software for your 3D printing needs, here’s a side-by-side comparison of key features:

| Feature | SketchUp | SolidWorks | Pro/E (Creo) | UG (NX) |

| Primary Strength | User-friendliness | Engineering power & usability balance | Parametric flexibility | Manufacturing integration |

| Learning Curve | Low | Moderate | Steep | Very steep |

| Best For 3D Printing | Basic shapes, concepts, architecture | Functional prototypes, mechanical parts | Complex designs, parametric control | Industrial parts, molds, tooling |

| Price Range | Low (free to $700/year) | Medium-High (\(4,000–\)8,000+) | High (\(6,000–\)10,000+) | Very High (\(7,000–\)15,000+) |

| Precision for 3D Prints | Good for basics | Excellent | Excellent | Excellent |

| Complex Geometry Handling | Basic-Moderate | Advanced | Advanced | Very Advanced |

| Ideal User | Beginner, hobbyist, architect | Engineer, product developer | Design engineer, manufacturer | Industrial designer, mold maker |

| 3D Printing Focus | Conceptual prints, decor | Functional prototypes, parts | Custom designs, industry parts | Production aids, industrial prints |

Choosing the Right 3D Printing Modeling Software: A Decision Guide

Selecting the best software depends on your specific needs and experience level. Here’s a step-by-step approach to making the right choice:

Step 1: Assess Your Experience Level

- Beginner: Start with SketchUp to learn 3D modeling basics without frustration

- Intermediate: Move to SolidWorks if you need more precision for functional prints

- Advanced: Consider Pro/E or UG if you’re working on complex industrial applications

Step 2: Define Your 3D Printing Goals

- Decorative prints or concepts: SketchUp offers the easiest path from idea to print

- Functional prototypes and mechanical parts: SolidWorks provides the best balance of usability and engineering tools

- Custom industrial components: Pro/E’s parametric flexibility will serve you well

- Manufacturing tools and molds: UG’s specialized features justify its complexity

Step 3: Consider Your Budget

- Entry-level: SketchUp’s free or low-cost options work for hobbyists

- Professional investment: SolidWorks offers strong value for product developers

- Industry-grade: Pro/E and UG represent significant investments best suited for commercial applications

Step 4: Evaluate Your Workflow Needs

- Speed and simplicity: SketchUp minimizes time between idea and print

- Design iteration: SolidWorks’ parametric tools make 修改 (modifications) easy

- Specialized applications: Pro/E or UG for industry-specific requirements

- Integration with other tools: All options support standard 3D printing file formats, but SolidWorks and UG offer better manufacturing integration

Yigu Technology’s Perspective

At Yigu Technology, we recognize that the right 3D modeling software bridges design and successful 3D printing. We recommend matching software to project complexity: SketchUp for initial concepts, SolidWorks for functional prototypes, and Pro/E or UG for industrial applications. The best choice balances usability with precision—enabling efficient creation of accurate, print-ready models that accelerate product development and reduce iteration time.

FAQ

1. Can all these software programs export files compatible with 3D printers?

Yes, all four software options support standard 3D printing file formats like STL and OBJ, which are compatible with most 3D printers and slicing software. Some (like SolidWorks and UG) offer additional export options and validation tools specifically for additive manufacturing workflows.

2. Do I need expensive software to create 3D printable models?

Not necessarily. For basic 3D prints and hobby projects, SketchUp’s free or low-cost versions provide sufficient tools. However, as your designs become more complex or require precise dimensions (like functional prototypes), investing in more advanced software like SolidWorks can save time and improve print quality.

3. Which software is best for beginners wanting to learn 3D printing modeling?

SketchUp is ideal for beginners due to its intuitive interface and gentle learning curve. It allows new users to create basic 3D models quickly and export them for 3D printing without mastering complex CAD concepts. As skills develop, users can transition to more advanced software like SolidWorks.