In sheet metal manufacturing, achieving consistent, accurate bends is critical—yet traditional manual bending often struggles with human error, inconsistent angles, and slow throughput. The CNC bending machining process solves these pain points by combining computer-controlled precision with automated operation, making it ideal for mass-produced parts (like automotive brackets) and custom components (such as electrical enclosures). Whether you’re a production manager aiming to reduce scrap rates or a technician learning to optimize setup, this guide breaks down the CNC bending process, common challenges, and solutions to ensure high-quality results.

1. What Is the CNC Bending Machining Process? Core Definition & Key Advantages

Before diving into steps, let’s clarify what makes CNC bending different from traditional methods:

Key Definition

The CNC bending machining process is a computer-controlled manufacturing technique that uses a press brake to bend sheet metal (e.g., steel, aluminum) into predefined shapes. It relies on 3D CAD designs and CAM-generated programs to automate critical parameters—including bending sequence, angle, pressure, and tool positioning—eliminating manual guesswork.

Why Choose CNC Bending Over Manual Bending?

A side-by-side comparison highlights the efficiency and precision benefits:

| Aspect | CNC Bending Machining Process | Traditional Manual Bending |

| Precision | ±0.1° angle accuracy; consistent across 1000+ parts | ±1° angle variation; depends on operator skill |

| Production Speed | 10–15 bends per minute (for small parts) | 2–3 bends per minute; slows with complex designs |

| Scrap Rate | 2–5% (due to automated checks) | 10–15% (due to human error) |

| Complexity Handling | Easily handles 5+ bend sequences (e.g., box-shaped parts) | Struggles with 3+ bends; risk of misalignment |

2. Step-by-Step Breakdown of the CNC Bending Machining Process

The CNC bending process follows a linear, repeatable workflow—from design to inspection. Each step builds on the previous one to ensure accuracy:

Step 1: Design & Programming

This foundational step sets the stage for error-free bending:

- CAD Design: Use software (e.g., SolidWorks, AutoCAD) to create 2D/3D drawings of the bent part. Critical details include:

- Final bend angles (e.g., 90°, 45°)

- Material thickness (e.g., 2mm aluminum)

- Bend radius (to avoid material cracking)

- CAM Programming: Import the CAD file into CAM software (e.g., Mastercam, SolidWorks CAM) to generate the press brake program. The software calculates:

- Bending sequence (order of bends to avoid tool collisions—e.g., bend the innermost angles first)

- Press force (e.g., 50 kN for 2mm steel)

- Tool selection (matching upper/lower dies to the part’s shape)

Pro Tip: Always add a “flat pattern” to the CAD file—this shows the unbent sheet metal size, which is critical for cutting.

Step 2: Material Preparation

Using the wrong material or size leads to failed bends. Follow these steps:

- Material Selection: Choose metal based on part requirements:

- Steel plates (e.g., Q235): For high-strength parts (e.g., machine frames)

- Aluminum plates (e.g., 6061): For lightweight parts (e.g., automotive trim)

- Stainless steel (e.g., 304): For corrosion-resistant parts (e.g., food industry equipment)

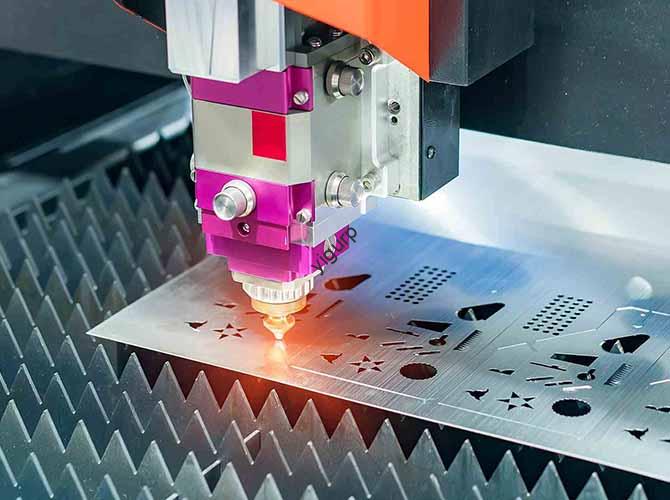

- Cutting: Use CNC shearing or laser cutting to trim large material into “blanks” (sheets matching the flat pattern size). For example:

- A 200mm × 150mm blank for a 100mm × 50mm × 50mm box part.

Step 3: Machine Setup & Mold Installation

Incorrect setup is the #1 cause of oversized or misshapen parts. Here’s how to avoid it:

- Die Selection: Match upper (punch) and lower (die) dies to the part’s bend radius:

- Use a 3mm radius die for 2mm aluminum (prevents cracking)

- Use a V-shaped die (e.g., 8mm V-width) for 90° bends

- Die Installation: Mount dies on the press brake’s upper ram (punch) and lower table (die). Secure them with clamps to avoid movement during bending.

- Machine Calibration: Adjust press brake parameters via the CNC control panel:

- Pressure: Set to 40 kN for 1.5mm steel (too much pressure crushes the material; too little leaves incomplete bends)

- Speed: 5–10 mm/s (faster speeds risk vibration; slower speeds reduce efficiency)

- Backgauge position: Align the backgauge (a stop that positions the blank) to the first bend’s location (e.g., 50mm from the die edge).

Step 4: CNC Bending Execution

This is the automated phase—but operator supervision is still key:

- Part Positioning: Place the cut blank on the press brake table. The backgauge pushes the blank to the correct position (no manual measuring needed).

- Program Start: Press “run” on the CNC panel. The press brake:

- Lowers the upper die (punch) to contact the blank

- Applies the preset pressure to bend the material

- Retracts the punch to release the bent part

- In-Process Check: After the first 2–3 parts, measure angles with a protractor to confirm accuracy. If off by 0.5°, adjust the CNC program’s angle offset.

Step 5: Post-Treatment & Quality Inspection

Even a perfectly bent part needs finishing and verification:

- Deburring: Use a file or sanding tool to remove sharp edges from bend points (prevents injury and improves part fit).

- Quality Inspection: Check key dimensions against the CAD file:

- Bend angle (use a digital protractor for ±0.05° accuracy)

- Part size (e.g., 100mm × 50mm for the box part)

- Surface quality (no cracks, dents, or material deformation)

Example: A manufacturer producing 1,000 aluminum electrical enclosures followed this process—scrap rate dropped from 12% (manual bending) to 3%, and production time was cut by 60%.

3. Common Challenges in CNC Bending & How to Solve Them

Even with automation, issues can arise. Here’s how to troubleshoot:

| Challenge | Cause | Solution |

| Bend Angle Too Small (e.g., 85° instead of 90°) | Material elastic recovery (metal springs back after bending) | Increase the programmed angle by 1–3° (e.g., program 92° for a 90° final bend) |

| Material Cracking at Bends | Bend radius too small; material too hard | Use a larger die radius (e.g., 4mm instead of 2mm); anneal the material to reduce hardness |

| Part Misalignment | Backgauge not calibrated; die loose | Recalibrate backgauge with a reference block; retighten die clamps |

| Press Brake Vibration | Speed too high; uneven material thickness | Reduce bending speed to 3–5 mm/s; use a thickness gauge to sort material (e.g., separate 1.9mm and 2.1mm steel blanks) |

4. Yigu Technology’s Perspective on CNC Bending Machining Process

At Yigu Technology, we’ve supported 250+ sheet metal manufacturers in optimizing their CNC bending machining process. From our experience, 70% of inefficiencies come from outdated programming or poor setup. Our Yigu CNC Press Brakes feature auto-calibration (cuts setup time by 40%) and integrated CAM software (preloads 1000+ bend parameters for common materials). For small shops, our training program teaches operators to reduce scrap rates to <5%—a client making automotive brackets saw a 50% productivity boost after 1 week of training. We also offer custom die sets for complex parts (e.g., curved bends), ensuring clients avoid tool-related delays.

FAQ: Common Questions About CNC Bending Machining Process

- Q: How do I calculate the right press force for CNC bending?

A: Use the formula: Force (kN) = Material Thickness (mm) × Material Width (mm) × Material Factor (e.g., 2.5 for steel, 1.5 for aluminum). For example, 2mm steel × 100mm width × 2.5 = 500 kN. Most CNC press brakes have built-in calculators to simplify this.

- Q: Can CNC bending handle thin materials (e.g., 0.5mm aluminum)?

A: Yes—but use a low-pressure setting (20–30 kN) and a narrow V-die (4mm width) to avoid material warping. Also, add a “hold time” (1–2 seconds) in the program to let the material set before releasing.

- Q: How often should I maintain a CNC press brake for bending?

A: Daily: Clean die surfaces and check clamp tightness. Weekly: Lubricate backgauge rails and calibrate pressure. Monthly: Inspect die wear (replace if edges are chipped) and test emergency stops. Following this schedule extends machine life by 3–5 years.