3D Printing Car Parts: From Custom Trim to Functional Engine Components

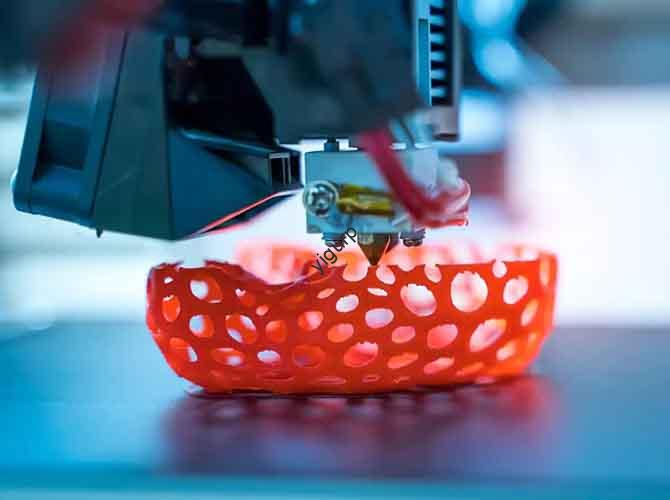

Beyond Prototypes: A Reality The way people think about 3D printing is changing fast. It used to be just for hobbyists making small trinkets and fake prototypes. Now, 3D printing has grown into a powerful manufacturing technology in the car industry. We’re not talking about what might happen in the future anymore. We’re talking about […]