Have you ever wondered how a digital design transforms into a physical object—whether it’s a custom toy, a medical implant, or a car part? The answer is 3D printing technology—a revolutionary manufacturing method that’s changing industries worldwide. But with its mix of materials, software, and machinery, it can feel overwhelming. This guide breaks down 3D printing’s core components, key techniques, and real-world uses, helping you solve questions like “Which technology fits my project?” or “How do I get started?”

1. What Is 3D Printing Technology?

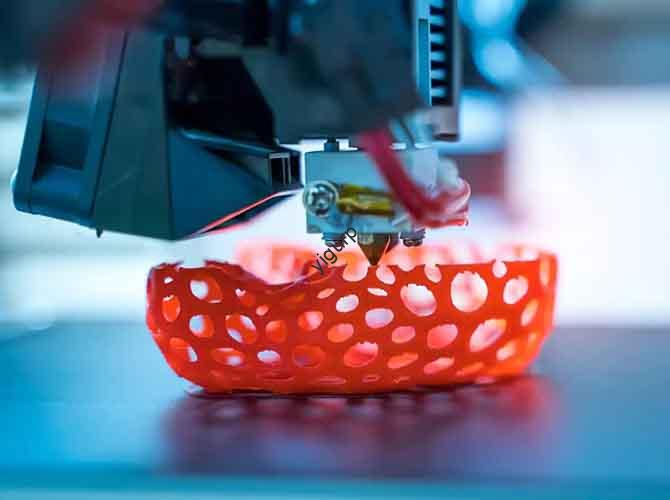

At its heart, 3D printing (additive manufacturing) builds objects layer by layer, using materials like plastic, metal, or resin—unlike traditional “subtractive” methods (e.g., cutting metal from a block) that waste material. Think of it as building a house with bricks: instead of pouring a whole foundation at once, you add one brick (layer) at a time until the structure is complete.

What makes it powerful? It lets you create complex shapes (e.g., hollow parts, intricate patterns) that traditional manufacturing can’t—all with less waste, faster prototyping, and customization at no extra cost.

2. The 4 Core Technologies Behind 3D Printing

3D printing isn’t a single tool—it’s a mix of four key technical areas that work together. Without any one of these, a 3D printer can’t function. Below’s a breakdown of each, with real-world examples of how they interact.

| Technical Area | Key Functions | How It Works with Other Areas | Example |

|---|---|---|---|

| Materials Science | – Selects suitable base materials (plastics, metals, etc.)- Handles materials (e.g., melting plastic, curing resin) | Materials determine which 3D printing technique to use (e.g., flexible resin needs UV curing, not heat) | For a medical implant, materials scientists choose biocompatible resin—this then requires a stereolithography (SLA) printer (electromechanical tech) to cure it |

| Computer-Aided Design (CAD) | – Creates digital 3D models- Optimizes models (e.g., adjusting size for printing) | CAD models are the “blueprint” for 3D printing—without a CAD file, there’s no design to print | A designer uses CAD software to draw a phone case; they shrink it by 2% to account for plastic shrinkage during printing (material science knowledge) |

| Electromechanical Control | – Controls printheads (e.g., extruding plastic)- Moves the printing platform precisely | Uses sensors and motors to follow CAD instructions—ensures layers are placed accurately | A fused deposition modeling (FDM) printer’s stepper motor (electromechanical part) moves the printhead along the CAD-designed path to lay down plastic filament |

| Information Technology (IT) | – Slices CAD models into layers (path planning)- Monitors printing remotely | Converts CAD models into machine-readable code (G-code) and tracks progress | IT systems slice a CAD model of a toy into 200 layers; the user checks the print’s status from their phone (remote monitoring) if the printer is connected to the internet |

3. The 2 Most Common 3D Printing Techniques

While there are dozens of 3D printing methods, two stand out for their popularity and versatility: FDM (for plastics) and SLA (for resin). Let’s compare them to help you choose the right one.

3.1 Fused Deposition Modeling (FDM): The “Everyday” Technique

FDM is the most common 3D printing method—you’ll find it in homes, schools, and small businesses.

- How it works: It heats thermoplastic filament (e.g., PLA, ABS) to a liquid state, then extrudes it through a printhead onto a platform. The filament cools and hardens, building layers one by one.

- Pros:

- Low cost (printers start at $200; filament is cheap).

- Easy to use (great for beginners).

- Works with tough plastics (good for functional parts like tool handles).

- Cons:

- Slow for complex models (thick layers = visible “steps”).

- Not ideal for super-detailed parts (e.g., tiny figurines).

- Example: A hobbyist uses an FDM printer to make a custom replacement knob for their old radio—they use PLA filament (easy to print) and finish it with sandpaper to smooth the layers.

3.2 Stereolithography (SLA): The “Detail” Technique

SLA is perfect for high-detail models—think jewelry, dental crowns, or miniatures.

- How it works: It uses a UV light source to cure liquid resin into solid layers. The printing platform dips into a resin tank; after each layer cures, the platform lifts slightly to add the next layer.

- Pros:

- Ultra-smooth surfaces (no visible layers).

- Great for tiny, intricate details (e.g., a 5mm tall figurine with facial features).

- Cons:

- More expensive (printers start at $500; resin costs more than filament).

- Resin needs post-processing (washing and curing with extra UV light).

- Example: A jewelry designer uses an SLA printer to make a prototype of a ring—they use clear resin to see the design’s details, then cast metal over the prototype to make the final product.

4. Real-World Applications of 3D Printing Technology

3D printing isn’t just for making toys—it’s transforming industries by solving unique problems. Here are three key areas where it’s making a difference.

4.1 Medical Industry: Custom Implants

Doctors use 3D printing to create implants that fit a patient’s body perfectly—something traditional manufacturing can’t do.

- Case: A patient needs a hip implant. Doctors scan the patient’s hip, create a CAD model of the implant, and 3D print it using biocompatible metal (e.g., titanium). The implant fits exactly, reducing recovery time by 30% compared to a standard implant.

4.2 Automotive Industry: Fast Prototyping

Car companies use 3D printing to test parts quickly—saving time and money.

- Scenario: A car manufacturer wants to test a new dashboard design. Instead of waiting 6 weeks for a traditional prototype, they 3D print it in 2 days using FDM (ABS filament, which is heat-resistant). They tweak the design 3 times in a week before finalizing it.

4.3 Education: Hands-On Learning

Schools use 3D printing to make abstract concepts concrete—like teaching biology with 3D-printed cell models.

- Example: A high school science teacher prints 3D models of a human heart (using SLA for detail) so students can hold and examine the valves—students report understanding the heart’s structure 50% better than with textbook diagrams alone.

5. Yigu Technology’s Perspective

At Yigu Technology, we’ve supported 2000+ users—from students to industrial clients—with 3D printing solutions. Our view? 3D printing is for everyone, but success depends on matching the technology to your goal. For beginners, start with FDM (low cost, easy to learn); for detailed parts, SLA is worth the investment. We also emphasize mastering the basics: a good CAD model (IT/design) and the right material (materials science) will fix 80% of printing problems. Looking ahead, we’ll see more AI integration—auto-adjusting parameters and predicting failures—but the core four technical areas will remain the foundation of 3D printing.

6. FAQ: Common Questions About 3D Printing Technology

Q1: How much does a 3D printer cost?

It depends on the technique: FDM printers start at $200 (hobbyist models) and go up to $10,000 (industrial models). SLA printers start at $500 (entry-level) and can cost $50,000+ for professional machines. Materials add $20–$100 per kilogram (filament) or $30–$100 per liter (resin).

Q2: Can 3D printing make functional parts (e.g., a replacement gear for a machine)?

Yes! FDM is great for functional parts—use ABS or PETG filament (tough and heat-resistant). For example, a small business owner 3D printed a replacement gear for their packaging machine using ABS; it lasted 6 months (same as the original metal gear) at 10% of the cost.

Q3: Do I need to know how to use CAD software to 3D print?

Not necessarily! Beginners can download pre-made CAD models from websites like Thingiverse (free) and print them directly. If you want to design custom parts, start with simple CAD software like TinkerCAD (browser-based, free)—most users learn the basics in 1–2 hours.