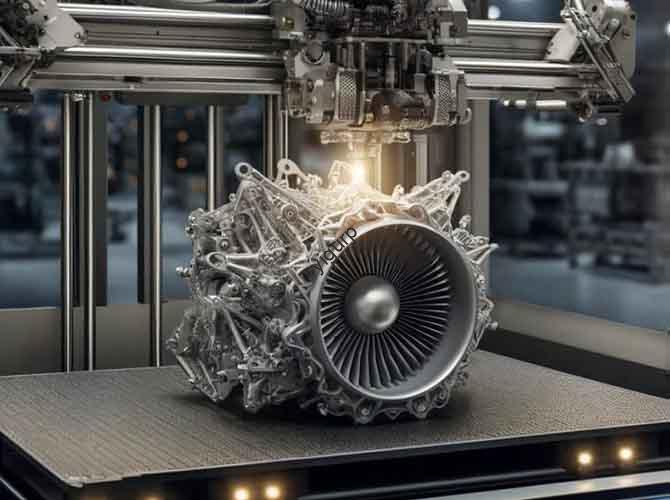

In metal additive manufacturing, how do we create complex, high-precision parts—like lightweight aerospace components or personalized medical implants—without the limits of traditional casting? The answer lies in 3D printing SLM technical (Selective Laser Melting), an advanced technology that melts metal powder layer by layer to build solid, durable parts. This article breaks down its core principles, key parameters, real-world applications, solutions to common challenges, and future trends, helping you leverage SLM to achieve high-quality metal part production.

What Is 3D Printing SLM Technical?

3D printing SLM technical (Selective Laser Melting) is a metal additive manufacturing process that uses a high-energy laser beam to fully melt and fuse metal powder particles into three-dimensional parts. Unlike other 3D printing methods (e.g., FDM for plastics), SLM works exclusively with metals—turning fine powders (5–50 μm in diameter) into dense, near-net-shape components with minimal post-processing.

Think of it as a “digital blacksmith”: instead of hammering hot metal, it uses a laser to “weld” tiny metal particles together, layer by layer, following a digital design. The result? Parts with 99.5%+ density—comparable to traditionally machined metal—plus the freedom to create shapes that would be impossible with casting or milling.

Core Principles of 3D Printing SLM Technical

SLM follows a linear, repeatable workflow that ensures precision and consistency. Here’s a step-by-step breakdown of how it works:

- Digital Design & Slicing:

- Start with a 3D CAD model of the part (e.g., an aerospace bracket or medical implant).

- Use slicing software to split the model into 2D layers (typically 20–100 μm thick)—each layer represents a cross-section of the final part.

- Powder Bed Preparation:

- A recoater blade spreads a thin layer of metal powder (e.g., titanium alloy, stainless steel) onto the build platform of the SLM machine.

- The platform lowers by the thickness of one layer (e.g., 50 μm) to prepare for the next step.

- Laser Melting:

- A high-power laser (usually fiber laser, 100–500 W) scans the powder bed according to the 2D slice data.

- The laser’s energy melts the metal powder to a temperature above its melting point (e.g., 1,668°C for pure titanium), fusing particles into a solid layer.

- Layer-by-Layer Building:

- The process repeats: recoater spreads new powder, laser melts the next layer, and the platform lowers. Each new layer fuses to the one below, building the part vertically.

- Post-Processing:

- Once printing is complete, the build chamber cools to room temperature (to prevent part warping).

- Remove the part from the powder bed, clean excess powder (via brushing or vacuuming), and perform optional post-processing (e.g., heat treatment to reduce stress, CNC machining to refine surfaces).

Key Parameters of 3D Printing SLM Technical (And How to Optimize Them)

SLM’s success depends on tuning critical parameters—get them wrong, and parts may have defects (e.g., porosity, warping). The table below lists the top parameters, their impact, and optimized ranges for common metals:

| Parameter | Definition | Impact on Part Quality | Optimized Range (By Metal) |

| Laser Power | The energy output of the laser (measured in watts, W). | Too low = powder not fully melted (porosity); too high = overheating (warping). | – Titanium Alloy: 150–250 W – Stainless Steel (316L): 200–300 W – Aluminum Alloy: 250–350 W |

| Scan Speed | How fast the laser moves across the powder bed (mm/s). | Too slow = excessive heat (part deformation); too fast = incomplete melting. | – Titanium Alloy: 500–800 mm/s – Stainless Steel (316L): 800–1,200 mm/s – Aluminum Alloy: 1,000–1,500 mm/s |

| Hatch Spacing | The distance between adjacent laser scan lines (μm). | Too narrow = overlapping melts (heat buildup); too wide = gaps (porosity). | – All Metals: 50–150 μm (match to powder particle size—e.g., 80 μm for 50 μm powder) |

| Layer Thickness | The height of each melted layer (μm). | Thinner layers = higher precision/smoother surfaces; thicker layers = faster prints. | – High-Precision Parts (Medical Implants): 20–50 μm – General-Purpose Parts (Aerospace Brackets): 50–100 μm |

| Build Chamber Atmosphere | The gas environment in the chamber (prevents oxidation). | Oxygen > 0.1% = metal oxidation (weak parts); inert gas (argon/nitrogen) is required. | – All Metals: Argon or nitrogen atmosphere with oxygen content < 0.05% |

3D Printing SLM Technical vs. Traditional Metal Manufacturing

Why choose SLM over casting, forging, or CNC machining? The table below contrasts their key strengths and weaknesses:

| Aspect | 3D Printing SLM Technical | Traditional Metal Manufacturing (Casting/Forging) |

| Design Freedom | Creates complex shapes (e.g., internal channels, lattice structures) impossible with casting. | Limited to simple shapes; complex designs require assembly of multiple parts. |

| Material Efficiency | Uses 95% of metal powder (unmelted powder is recyclable); minimal waste. | Wastes 30–50% of material (e.g., cutting scrap in CNC machining). |

| Lead Time | Produces parts in 1–5 days (no mold making); ideal for prototyping or small batches. | Takes 2–8 weeks (mold making + production); better for large batches (1,000+ units). |

| Part Density | Achieves 99.5–99.9% density (comparable to forged metal); high strength. | Cast parts: 95–98% density (risk of porosity); forged parts: 99.5%+ density (but limited shapes). |

| Cost for Small Batches | Low (no mold costs); \(500–\)5,000 per part for small runs (1–100 units). | High (mold costs \(10k–\)100k); \(100–\)1,000 per part for large runs. |

Real-World Applications of 3D Printing SLM Technical

SLM’s ability to create strong, complex metal parts makes it indispensable in high-tech industries. Here are 3 key application areas with concrete examples:

1. Aerospace Industry

- Challenge: Need lightweight, high-strength parts to reduce aircraft fuel consumption—traditional casting can’t make hollow or lattice structures.

- Solution: SLM prints titanium alloy engine brackets with internal lattice patterns. These brackets are 40% lighter than forged counterparts while maintaining the same strength.

- Example: Airbus uses SLM to print 3D-optimized fuel nozzle components for its A350 aircraft. The parts reduce fuel burn by 5% and cut production time from 6 weeks to 1 week.

2. Medical Field

- Challenge: Personalized medical implants (e.g., hip replacements) must fit a patient’s unique anatomy—traditional sizing uses “one-size-fits-most” parts that often cause discomfort.

- Solution: SLM uses patient CT scans to print custom titanium hip implants with porous surfaces (promotes bone growth into the implant).

- Case: A hospital in Germany used SLM to print 50 custom hip implants. Patient recovery time decreased by 30%, and implant failure rates dropped from 8% to 1%.

3. Automotive Industry

- Challenge: Prototyping new car parts (e.g., gear housings) quickly to test designs—traditional casting takes weeks to make molds.

- Solution: SLM prints stainless steel gear housing prototypes in 3 days. Engineers test multiple designs in 2 weeks (vs. 2 months with casting), speeding up product launches.

Yigu Technology’s Perspective

At Yigu Technology, we see 3D printing SLM technical as a game-changer for metal manufacturing. Our SLM machines integrate smart features: real-time laser power monitoring (prevents porosity) and automatic powder recycling (cuts material costs by 20%). We’ve helped aerospace clients reduce part weight by 35% and medical clients shorten implant delivery time by 50%. As AI advances, we’re adding predictive maintenance to our SLM systems—soon, they’ll auto-adjust parameters to fix defects mid-print, making high-quality metal 3D printing even more accessible.

FAQ

- Q: What metal materials can be used in 3D printing SLM technical?

A: Common materials include titanium alloys (Ti-6Al-4V), stainless steel (316L, 17-4 PH), aluminum alloys (AlSi10Mg), and superalloys (Inconel 718). We also support custom powder blends for specialized applications (e.g., biocompatible alloys for medical use).

- Q: How long does it take to print a part with SLM?

A: It depends on size and complexity. A small medical implant (50mm×50mm×50mm) takes 8–12 hours; a large aerospace bracket (200mm×200mm×100mm) takes 48–72 hours. Our multi-laser SLM machines can cut time by 50% for large parts.

- Q: Is post-processing required for SLM parts?

A: Basic post-processing (powder cleaning, heat treatment to reduce stress) is required for all parts. For high-precision applications (e.g., medical implants), optional CNC machining or polishing can refine surfaces to Ra < 0.8 μm.