In the hyper-competitive mobile phone industry, where consumer preferences shift overnight and new technologies emerge constantly, the ability to turn ideas into testable prototypes quickly is no longer a luxury—it’s a necessity. Traditional prototyping methods like CNC machining and injection molding have long been the norm, but they often leave R&D teams stuck in slow, costly, and inflexible cycles. So, how can brands keep up? The answer lies in 3D printing mobile phone prototype models—a solution that addresses the biggest pain points of mobile device development. Below are the five core advantages that make it essential for modern R&D workflows.

1. Speed: Slash Prototyping Time to Accelerate Product Launches

The mobile market waits for no one. A delay of just a few weeks in prototyping can mean missing a critical launch window. 3D printing eliminates this risk by delivering prototypes in a fraction of the time traditional methods require.

Prototyping Time Comparison: 3D Printing vs. Traditional Methods

| Method | Average Turnaround Time | Best For |

|---|---|---|

| 3D Printing | 1–3 business days | Fast iterations, urgent designs |

| CNC Machining | 7–14 business days | High-strength metal parts |

| Injection Molding | 14–28 business days | Mass production (not prototyping) |

Take a real-world example: A startup developing a budget smartphone needed to test three different back cover designs. Using CNC machining, each prototype took 10 days—21 days total for revisions. With 3D printing, they had the first set of prototypes in 2 days and finalized the design in just 5 days. This speed lets teams test, adjust, and iterate at the pace the market demands, cutting overall product development time by 40–50%.

2. Customization: Unlock Design Freedom for Unique Devices

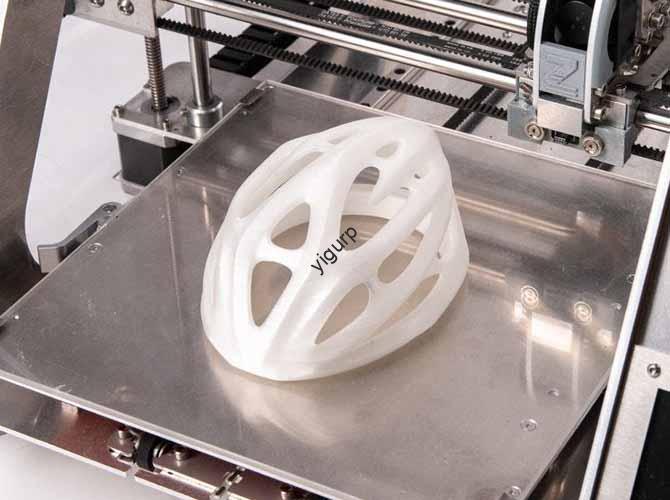

Today’s consumers want phones that stand out—and that starts with bold, innovative designs. Traditional methods struggle with complex shapes (like curved edges, hollow structures, or integrated hinges) because they rely on cutting or molding from a single block. 3D printing changes this by building parts layer by layer.

What Makes 3D Printing So Flexible?

- No design constraints: It can print intricate details (e.g., micro-ventilation holes for heat management) without splitting the part into pieces.

- Instant tweaks: Modify a CAD file in 1–2 hours and start printing the updated prototype the same day—no need to retool.

For instance, when a brand wanted to test a foldable phone’s hinge mechanism (a part with 12 moving components), 3D printing created a fully functional prototype in 3 days. Traditional methods would have required 3 weeks and custom jigs. This flexibility lets designers focus on innovation, not limitations—directly addressing the market’s hunger for personalized, one-of-a-kind devices.

3. Cost-Efficiency: Minimize Risk for Low-Volume Prototyping

For R&D teams, testing 5–10 design versions is standard—but traditional methods make this expensive. Injection molding requires $2,000–$10,000 for molds, and CNC machining charges by the hour for tooling. 3D printing eliminates these upfront costs, making low-volume prototyping affordable.

Where 3D Printing Cuts Costs

- No tooling fees: Skip the $1,000+ molds or jigs needed for traditional methods.

- Less material waste: It uses only 60–70% of the material CNC machining does, as it builds parts layer by layer (no cutting away excess).

- Cheaper iterations: Changing a design costs $5–$20 (for material) instead of $500–$1,000 (for new tooling).

A mid-sized brand once saved $8,000 by using 3D printing for 8 prototype iterations of a camera bump design. Without 3D printing, they would have paid for 8 sets of CNC tooling. This cost-efficiency lets teams test more, risk less—critical for avoiding costly mistakes in mass production.

4. Material Versatility: Match the Final Product’s Feel and Performance

A prototype isn’t useful if it doesn’t behave like the real thing. 3D printing offers a wide range of materials that mimic the look, texture, and function of final phone parts—from soft rubber buttons to rigid metal frames.

3D Printing Materials for Mobile Prototypes

| Material | Key Traits | Ideal Prototype Use-Cases |

|---|---|---|

| ABS Plastic | Lightweight, impact-resistant | Phone shells, battery covers |

| Resin | Smooth, high-detail | Screen bezels, logos, camera lenses |

| Stainless Steel | Strong, corrosion-resistant | Internal frames, SIM card trays |

| TPU Rubber | Flexible, shock-absorbent | Buttons, grip pads, protective cases |

For example, using TPU rubber for a prototype’s power button lets teams test how it feels to press (soft vs. firm) before mass production. Using stainless steel for an internal frame lets engineers check heat resistance. This versatility ensures prototypes aren’t just “lookalikes”—they’re functional stand-ins for the final product.

5. Precision: Micron-Level Accuracy for Perfect Fits

Mobile phones are tiny—even a 0.2mm error can break a part (e.g., a charging port that doesn’t fit a cable). 3D printing delivers micron-level precision (down to 0.02mm), ensuring prototypes match CAD designs exactly.

Why does this matter?

- Fewer reworks: A precise prototype means fewer changes during mass production (saving time and money).

- Faster validation: Engineers can quickly test if parts (e.g., circuit boards, batteries) fit together—no guesswork.

When a brand tested a prototype camera module with 3D printing, the fit was so precise they could skip 2 rounds of retooling. For complex parts like hinges or speaker grilles, this accuracy is non-negotiable—it’s the difference between a prototype that works and one that doesn’t.

Yigu Technology’s Take

At Yigu Technology, we’ve helped 50+ mobile brands streamline prototyping with 3D printing. Our clients see 45–65% faster iteration cycles and 30–40% lower prototyping costs. We focus on pairing the right material with each project—e.g., resin for high-detail logos, stainless steel for structural parts—to ensure prototypes mirror final products. 3D printing isn’t just a tool; it’s a way for brands to turn ideas into market-ready devices faster than ever. In the mobile industry, speed and innovation win—and 3D printing delivers both.

FAQ

- Can 3D printed prototypes be used for user testing?Yes! With materials like ABS plastic or TPU rubber, prototypes look and feel like real phones. Brands use them to test ergonomics (e.g., how the phone fits in a hand) and user preferences (e.g., button placement).

- How many iterations can I do with 3D printing before costs add up?3D printing stays cost-effective for 1–20 iterations. For 20+ prototypes, traditional methods like CNC may become cheaper—but 3D printing still saves time on setup.

- Is 3D printing accurate enough for small parts like microphones or speakers?Absolutely. With resin or stainless steel, 3D printing can create parts as small as 1mm with 0.02mm precision—perfect for tiny components like microphones or speaker grilles.