If you’ve ever struggled with slow prototyping, high manufacturing costs, or limited design flexibility when creating 3D parts—whether for medical devices or industrial molds—3D printing inkjet technology is your solution. This advanced additive manufacturing method sprays and cures materials layer by layer, but how do you master its workflow? Which industries benefit most? And how can you fix common issues like uneven material deposition or slow curing? This guide answers all these questions, helping you leverage 3D printing inkjet technology for reliable, high-quality results.

What Is 3D Printing Inkjet Technology?

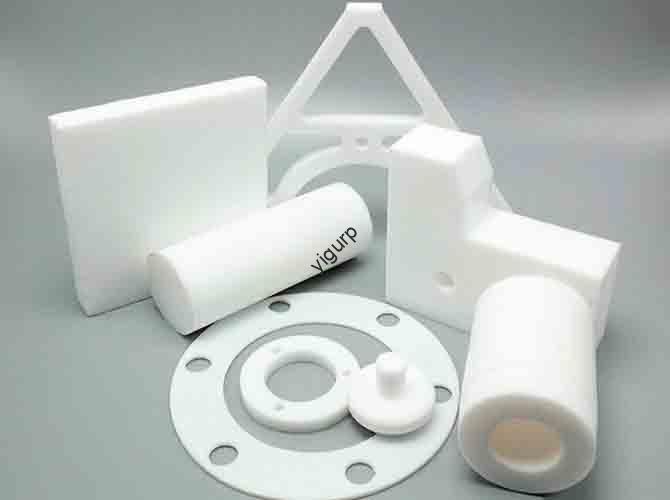

3D printing inkjet technology (also called material jetting) is an additive manufacturing process that creates 3D objects by precisely spraying materials—such as photopolymers, metal powders, or plastics—onto a build platform, then curing them layer by layer. Unlike FDM (Fused Deposition Modeling), which melts and extrudes filament, inkjet technology works like a 2D inkjet printer but builds upward, layer by layer.

Think of it like decorating a cake with a piping bag: the piping bag (printhead) squeezes out frosting (3D printing material) in precise patterns, and each layer of frosting builds up to form a 3D shape—except 3D printing inkjet uses digital models and curing (e.g., UV light) to set the material instantly. For manufacturers and designers, this means the ability to create complex, detailed parts directly from digital files—no molds or tooling required.

Key traits of 3D printing inkjet technology:

- High detail: Captures tiny features (down to 0.1mm), perfect for intricate parts like medical surgical guides.

- Material versatility: Works with photopolymers (most common), metal powders, and even food-safe materials.

- Fast turnaround: Converts a 3D design to a physical part in hours, not days—ideal for rapid prototyping.

Step-by-Step Process of 3D Printing Inkjet Technology

3D printing inkjet technology follows a linear, repeatable workflow to ensure consistency. Below is a detailed breakdown, from design to final inspection:

- Design the 3D Model in CAD Software

Start with CAD (Computer-Aided Design) software (e.g., SolidWorks, AutoCAD) to create a 3D model of the part. Focus on:

- Layer height compatibility: Design the model to fit the printer’s minimum layer height (usually 0.02-0.1mm for inkjet).

- Overhangs: Avoid overhangs greater than 45° (unless using support materials—inkjet printers can spray soluble supports for complex shapes).

- Material selection: Match the model’s features to the material (e.g., use photopolymers for high-detail medical parts).

Export the model as an STL file (standard for 3D printing) and use tools like Meshlab to fix gaps or overlapping faces.

- Prepare the Printer & Material

- Choose the right material: Load photopolymers (most common for inkjet) into the printer’s material cartridges—ensure the material is at room temperature (20-25°C) to prevent clogs.

- Calibrate the build platform: Level the platform to ensure even material deposition (unlevel platforms cause thin or thick layers).

- Set curing parameters: For photopolymers, adjust UV light intensity (usually 200-400 mW/cm²) and exposure time (2-5 seconds per layer)—follow the material manufacturer’s recommendations.

- Generate Print Instructions (Slicing)

Import the STL file into slicing software (e.g., Stratasys GrabCAD Print, 3D Systems 3D Sprint). Here, you:

- Split the 3D model into thin layers (0.05-0.1mm thick).

- Define support structures (if needed): Select soluble supports for hard-to-reach areas (e.g., internal holes).

- Set print speed: 5-10 mm/s (faster speed = shorter print time; slower speed = better detail).

- Run the Printing Process

Start the printer— it will automatically follow the slicing instructions:

- The printhead moves back and forth, spraying material onto the build platform to form the first layer.

- For photopolymers, a UV light cures the layer instantly (sets the material so it doesn’t smudge).

- The build platform lowers by the thickness of one layer (e.g., 0.05mm), and the process repeats until the part is complete.

- Post-Process the Part

Turn the printed part into a finished product:

- Remove supports: For soluble supports, soak the part in a cleaning solution (e.g., isopropyl alcohol) for 10-20 minutes—supports dissolve, leaving a clean part.

- Final curing: Place the part in a UV curing station for 15-30 minutes (strengthens the material by 20-30%).

- Finish (optional): Sand with 400-800 grit sandpaper for a smooth surface, or paint with inkjet-compatible paint for aesthetics.

3D Printing Inkjet Technology: Applications & Material Comparison

Not all materials or industries use 3D printing inkjet technology the same way. Below is a table to help you choose the right combination of material and application:

| Industry | Common Material | Typical Parts Produced | Key Benefits of Inkjet Technology |

| Medical | Photopolymers (biocompatible) | Surgical guides, tissue models, dental crown prototypes | High detail (matches human anatomy); biocompatible materials (safe for medical use) |

| Manufacturing | Photopolymers, metal powder composites | Industrial molds, complex machine parts, product prototypes | Fast prototyping (cuts development time by 50%); no tooling costs |

| Construction | Concrete-based inks, plastic composites | Architectural models, small building components (e.g., wall panels) | Creates custom shapes (hard to achieve with traditional construction); low material waste |

| Consumer Goods | Food-safe photopolymers, plastics | Custom toys, jewelry, phone cases | Personalization (print unique designs); fast production (1-2 hours per part) |

Advantages & Challenges of 3D Printing Inkjet Technology

Like any additive manufacturing method, 3D printing inkjet technology has strengths and limitations. Below is a balanced breakdown to help you set expectations:

Advantages (Why It’s Worth Investing In)

- Complex design flexibility: Creates parts with internal channels, lattice structures, or undercuts—shapes impossible with traditional machining or FDM.

- Low waste: Uses only the material needed for the part (waste <5% vs. 30-40% for CNC machining)—saves money on materials.

- Consistent quality: Every part matches the digital model (tolerances ±0.02mm)—critical for batch production (e.g., 100 identical medical guides).

Challenges (And How to Overcome Them)

- Size limitations: Most inkjet printers have small build volumes (<0.5m³)—large parts (e.g., full-size architectural models) need to be printed in sections.

Solution: Split the model into smaller sections in CAD, print separately, then assemble with epoxy (for photopolymers) or metal adhesives (for metal composites).

- Slow printing speed for large parts: A 10cm industrial mold takes 4-6 hours to print—slower than FDM for large objects.

Solution: Increase layer height (to 0.1mm) and print speed (to 10 mm/s) for non-critical parts; use multiple printers for batch production.

- Material cost: Photopolymers cost \(50-\)100 per liter (vs. \(20-\)30 per kg for PLA)—a barrier for high-volume production.

Solution: Use inkjet for prototypes or high-detail parts; switch to FDM for low-detail, high-volume items (e.g., simple plastic brackets).

Real-World Case Studies of 3D Printing Inkjet Technology

3D printing inkjet technology is transforming industries with its speed and detail. Below are specific examples of its impact:

1. Medical: Surgical Guides for Knee Surgeries

A hospital needed custom surgical guides to help surgeons align implants during knee replacement surgeries. They used:

- 3D printing inkjet technology with biocompatible photopolymers.

- Process: Scanned patients’ knees to create 3D models, printed guides in 2 hours, then cured them for 30 minutes.

- Result: Surgeons reported a 30% reduction in surgery time (guides eliminated guesswork); patients had faster recovery (implants were aligned more accurately). Traditional guides (made via CNC machining) took 3 days and cost 5x more.

2. Manufacturing: Industrial Mold Prototypes

An automotive parts manufacturer wanted to test a mold for a new car door handle. They used:

- 3D printing inkjet technology with high-temperature photopolymers (resists up to 150°C).

- Process: Designed the mold in CAD, printed it in 4 hours, then used it to cast 50 plastic door handles.

- Result: The mold worked perfectly—no cracks or deformities in the cast parts. The team iterated 2 more mold designs in a week (vs. 2 weeks with traditional mold-making), cutting development time by 60%.

3. Construction: Architectural Models

An architecture firm needed a detailed model of a new office building (1:50 scale) to show clients. They used:

- 3D printing inkjet technology with plastic composites (resistant to breaking).

- Process: Imported the building’s CAD model into slicing software, printed the model in 3 sections (total print time 8 hours), then assembled with glue.

- Result: The model had tiny details—like window frames and balcony railings—that hand-built models couldn’t replicate. Clients approved the design faster, and the firm won the project.

Future Trends of 3D Printing Inkjet Technology

As technology advances, 3D printing inkjet technology will become even more versatile. Here are three trends to watch:

- Faster Printing Speeds: New printhead designs (with 1,000+ nozzles instead of 100) will cut print time by 50%—a 10cm part will take 2 hours instead of 4.

- New Material Development: Researchers are creating inkjet-compatible materials like recycled photopolymers (reducing cost by 30%) and conductive inks (for electronic parts like circuit boards)—expanding use cases to electronics manufacturing.

- Automation & AI Integration: AI will automatically optimize slicing settings (e.g., adjust layer height for detail vs. speed) and detect errors (e.g., material clogs) in real time—reducing human intervention and improving consistency.

Yigu Technology’s Perspective on 3D Printing Inkjet Technology

At Yigu Technology, we see 3D printing inkjet technology as a game-changer for rapid prototyping and custom manufacturing. Our inkjet 3D printers (e.g., Yigu Tech IJ4) are optimized for photopolymers—they have dual UV curing lamps for fast setting and a 0.4m³ build volume for medium-size parts. We also offer a free material sample kit (including biocompatible and high-temperature photopolymers) to help users test the technology. For small businesses, we provide training on slicing and post-processing to avoid common issues like uneven curing. 3D printing inkjet technology isn’t just about printing parts—it’s about making innovation faster and more accessible.

FAQ: Common Questions About 3D Printing Inkjet Technology

- Q: Can 3D printing inkjet technology use metal materials?

A: Yes! Some inkjet printers spray metal powder mixed with a binding material (binder jetting). After printing, the part is “debinded” (removes the binder) and sintered (heated to fuse metal particles)—resulting in a solid metal part. This is ideal for small metal components like aerospace fasteners.

- Q: How long do 3D printed inkjet parts last?

A: It depends on the material and use: Photopolymer parts last 3-5 years indoors (resist fading and cracking); outdoor parts (e.g., architectural models) last 1-2 years—apply a UV-resistant clear coat to extend life to 3+ years. Metal inkjet parts last as long as traditionally machined metal parts (10+ years).

- Q: Is 3D printing inkjet technology suitable for high-volume production (e.g., 1,000 parts)?

A: It depends on the part size and detail. For small, high-detail parts (e.g., dental crown prototypes), yes—use multiple inkjet printers to scale production. For large, low-detail parts (e.g., plastic buckets), no—FDM is cheaper and faster for high volume. Inkjet is best for low-to-medium batches (10-100 parts) where detail matters.