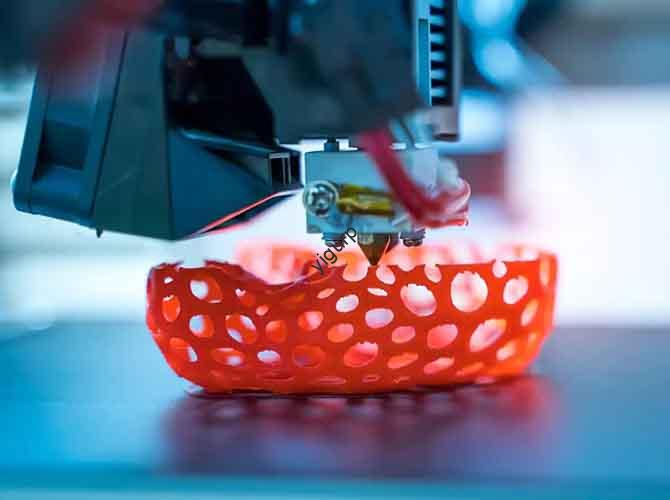

Dinosaur models have long fascinated both kids and adults—but 3D printing has taken this hobby to a whole new level. It lets you create highly detailed, customizable models at home or in small workshops. Yet many people struggle with questions like: Which material should I use? How do I get smooth, realistic details? What post-processing steps are essential? This guide answers these questions by breaking down the key aspects of 3D printed dinosaur models, helping you avoid common mistakes and create impressive pieces.

1. Dinosaur Model Types: Choose the Right Style for Your Needs

3D printing offers a far wider range of dinosaur models than traditional manufacturing. Whether you want a scientifically accurate T-Rex or a cute cartoon Stegosaurus, there’s an option for you. Below is a breakdown of the most popular types:

| Model Category | Key Features | Ideal For | Example Use Case |

|---|---|---|---|

| Realistic Species | Follows fossil records; includes fine details (scales, teeth) | Educators, serious collectors, museum displays | A 1:20 scale Triceratops for a school science project |

| Movable Joints | Joints (e.g., neck, legs) that rotate; requires assembly | Kids, interactive displays | A Pterosaur with a movable wing to “fly” during play |

| Integrated Movable | No assembly needed—joints print as one piece | Beginners, quick projects | A Velociraptor with a bending tail that works right out of the printer |

| Creative Designs | Mixes genres (e.g., “dragon-dinosaur hybrids”) or cartoon styles | Decor, gifts, hobbyists | A pastel-colored “cute T-Rex” for a child’s bedroom shelf |

Why does this matter? Picking the wrong type can lead to frustration. For example, a complex movable-joint model might be too hard for a beginner, while a simple static model might not satisfy a collector seeking realism.

2. 3D Printing Materials: Match Material to Your Goals

The material you choose directly impacts your model’s strength, appearance, and ease of printing. Many enthusiasts waste time (and money) using the wrong material—so let’s compare the most common options:

3.1 Common Materials (Pros & Cons)

- PLA (Polylactic Acid):

- Pros: Easy to print (no heated bed needed for most printers), low odor, comes in bright colors.

- Cons: Low strength (breaks easily if dropped), not heat-resistant (warps in direct sunlight).

- Best For: Beginners, colorful models, static displays (e.g., a cartoon dinosaur).

- ABS (Acrylonitrile Butadiene Styrene):

- Pros: Stronger than PLA, heat-resistant, can be sanded to a smooth finish.

- Cons: Needs a heated bed, emits fumes (requires ventilation), trickier to print.

- Best For: Movable models (e.g., jointed dinosaurs) or outdoor displays.

- Resin:

- Pros: Ultra-high detail (captures tiny scales or skin texture), smooth surface.

- Cons: Requires a resin printer (more expensive), needs UV curing, toxic if not handled properly.

- Best For: Highly realistic models (e.g., a 3-inch Microceratus with visible skin folds).

Think of materials like paintbrushes: PLA is a basic brush for quick sketches, ABS is a sturdy brush for durable art, and resin is a fine-tip brush for intricate details.

3. Printing Accuracy & Detail: How to Get Realistic Results

One of the biggest draws of 3D printing is its ability to create fine details—but only if you optimize your setup. Many users end up with blurry scales or rough edges because they ignore key factors. Here’s a step-by-step guide to boost accuracy:

- Choose the Right Printer Resolution: Use a layer height of 0.15–0.2mm for most models. For ultra-fine details (e.g., dinosaur teeth), go down to 0.1mm.

- Optimize Infill: Use 10–20% infill for static models (saves material) and 30–50% for movable models (adds strength).

- Add Supports Strategically: Supports are needed for overhangs (e.g., a Pterosaur’s wing), but too many will leave marks. Use “tree supports” (less messy) instead of block supports.

Example: A user once printed a T-Rex head with blurry eyes—until they lowered the layer height to 0.1mm and added small supports under the eye sockets. The result? Sharp, lifelike eyes that made the model look professional.

4. Post-Processing: Turn a “Rough Print” into a Polished Model

Even the best 3D print needs post-processing to look its best. Skipping these steps leads to models with layer lines, support marks, or dull colors. Below is a timeline of essential post-processing steps (from start to finish):

| Step | Time Needed | What It Does | Tools Required |

|---|---|---|---|

| 1. Remove Supports | 5–15 mins | Eliminates temporary structures used during printing | Pliers, craft knife (for small parts) |

| 2. Sanding | 20–40 mins | Smooths layer lines and support marks | Sandpaper (200-grit, then 400-grit) |

| 3. Priming | 10 mins (plus drying time) | Creates a base for paint to stick to | Spray primer (gray or white) |

| 4. Coloring | 30–60 mins | Adds realism and personality | Acrylic paints, small brushes |

Pro Tip: For resin models, skip sanding (they’re already smooth) but add a clear coat after coloring to protect the paint.

Yigu Technology’s Perspective on 3D Printing Dinosaur Models

At Yigu Technology, we see 3D printed dinosaur models as a perfect blend of creativity and technology. Many of our clients—from hobbyists to educational brands—struggle with material selection or detail issues. For example, a children’s toy company once struggled with fragile PLA models until we recommended our modified ABS filament (lower odor, easier to print). We also design 3D printer accessories (e.g., precision sanding tools) to simplify post-processing. As 3D printing evolves, we’ll keep developing solutions that make it easier for everyone to turn their dinosaur ideas into high-quality, durable models.

FAQ (Frequently Asked Questions)

- Q: Can I 3D print a large dinosaur model (e.g., 1m tall) at home?A: Yes—but you’ll need to split the model into smaller parts (e.g., body, legs, head) using 3D software (like Meshmixer). Print each part separately, then glue them together with strong adhesive (e.g., epoxy). This avoids size limits of home printers.

- Q: Why does my PLA dinosaur model warp when I paint it?A: PLA melts at low temperatures—if you use spray paint or primer that’s too hot (e.g., from a can held too close), it can warp the plastic. Solution: Hold the paint can 8–10 inches away and use light, even coats.

- Q: How long does it take to 3D print a small dinosaur model (e.g., 10cm tall)?A: It depends on detail and printer speed, but usually 2–4 hours. A simple static model might take 2 hours, while a movable-joint model with fine details could take 4 hours. To save time, use a faster print speed (but avoid speeds over 60mm/s—this reduces quality).