The automotive industry is no stranger to innovation—and 3D printing has emerged as one of its most game-changing tools. Over the past decade, additive manufacturing (the technical term for 3D printing) has moved beyond just prototyping to reshape how cars are designed, built, repaired, and customized. For automakers, suppliers, and even custom shops, understanding 3D printing’s role isn’t just a competitive edge—it’s a way to cut costs, boost efficiency, and unlock designs that were once impossible. This guide breaks down 3D printing’s impact on the automotive sector, from its core advantages to real-world success stories and how to choose the right tools for the job.

Why 3D Printing Is a Game-Changer for Automotive

Traditional automotive manufacturing relies on tooling, assembly lines, and mass production—great for large volumes but slow, rigid, and wasteful. 3D printing flips this script by addressing two of the industry’s biggest pain points: innovation limits and supply chain inefficiencies. Let’s break down these advantages.

1. Unlocking Product Innovation (No More Design Rules)

Traditional processes like casting or CNC machining have strict limits—you can’t easily make parts with complex internal structures, lattice patterns, or hollow designs. 3D printing changes that by building parts layer by layer, letting engineers create shapes that were once just ideas.

Key innovations made possible by 3D printing:

- Integrated features: Parts with built-in electrical wiring (no need for separate assembly).

- Weight reduction: Lattice structures that cut part weight by 30–50% (critical for electric vehicles, where lighter weight = longer range).

- Multi-material parts: Components that combine hard and flexible polymers (e.g., a dashboard clip with a rigid base and soft grip).

Example: EDAG’s Light Cocoon concept car uses 3D printed lattice frames that mimic insect exoskeletons—strong enough to support the vehicle but so light they reduce overall weight by 40%. This design would be impossible with traditional manufacturing.

2. Streamlining the Supply Chain (Faster, Cheaper, Greener)

Automotive supply chains are notoriously complex—parts often travel thousands of miles from factories to assembly lines, with warehouses full of inventory. 3D printing simplifies this in three big ways:

| Supply Chain Benefit | How 3D Printing Delivers It |

|---|---|

| Shorter lead times | Eliminates tooling (which can take 4–8 weeks to make) — 3D printed parts are ready in days. |

| Less waste | Uses only the material needed for the part (traditional machining wastes 50–70% of raw material). |

| On-demand production | Print spare parts when needed (no more storing thousands of rarely used components). |

| Decentralized manufacturing | Print parts near assembly plants or dealerships (cuts shipping costs and delays). |

Data Point: A 2023 study by the Automotive Industry Action Group (AIAG) found that automakers using 3D printing for spare parts reduced inventory costs by 35% and cut lead times for hard-to-find parts from 6 weeks to 3 days.

Where 3D Printing Shines in the Automotive Lifecycle

3D printing isn’t a one-size-fits-all tool—it excels at specific stages of a car’s lifecycle. Below are the four key areas where it’s making the biggest impact, with real-world use cases.

1. Prototyping (Turn Ideas into Parts in Days)

Prototyping is the automotive industry’s “testing ground”—engineers need to quickly iterate on designs (e.g., a new headlight housing or gear) to fix flaws before mass production. Traditional prototyping can take weeks and cost tens of thousands of dollars for tooling.

3D printing solves this by:

- Producing highly detailed prototypes that match the final part’s look and feel (e.g., SLA 3D printing makes clear resin prototypes that mimic glass for headlights).

- Cutting prototyping time from 4–6 weeks to 3–5 days.

- Reducing costs by 50–70% (no tooling = no upfront expenses).

Case Study: Ford uses FDM 3D printing to prototype engine components for its F-150 pickup trucks. In 2022, the company reduced prototyping time for a new intake manifold from 6 weeks to 4 days, saving $120,000 in tooling costs for that single part.

2. Spare Parts (Never Run Out Again)

Anyone who’s owned an older car knows the frustration: needing a part that’s no longer in production. 3D printing fixes this with digital inventory—store CAD files of parts instead of physical components, and print them on demand.

Key benefits for spare parts:

- Revive old models: Reverse-engineer rare parts (e.g., a 1960s Porsche door handle) using 3D scans, then print exact replicas.

- Cut dealership costs: Dealerships no longer need to stock hundreds of low-demand parts (e.g., a specific sensor for a 2015 SUV).

- Faster repairs: A broken suspension bracket for a delivery van can be printed locally in 2 days, instead of waiting 2 weeks for a shipment.

Example: Volkswagen’s “3D Printing Center” in Wolfsburg, Germany, prints over 10,000 spare parts annually for its classic cars (e.g., the 1963 Beetle). Owners once waited 3 months for these parts—now they get them in 5 days.

3. Customization (Build Cars That Fit Every Driver)

Traditional manufacturing makes customization expensive—changing a part’s color or size often requires new tooling. 3D printing lets automakers offer custom parts at little extra cost, from personalized dashboard trims to driver-specific seat cushions.

Who benefits most?

- Luxury brands: Porsche offers 3D printed custom seat inserts that match a driver’s body shape (improves comfort during long drives).

- Custom shops: Small garages use 3D printing to create one-of-a-kind parts (e.g., a custom grille for a vintage Mustang) without expensive tooling.

- Electric vehicle (EV) makers: Custom battery brackets that fit unique EV chassis designs (3D printing avoids the cost of making new molds for each design).

Case Study: Tesla uses SLS 3D printing to make custom wiring harness brackets for its Model Y. Each bracket is tailored to the vehicle’s specific configuration (e.g., long-range vs. standard battery), reducing wiring clutter and improving assembly speed.

4. Production Parts (Simplify Assembly, Cut Weight)

Until recently, 3D printing was too slow for mass production—but new technologies (like MJF and SLM) have changed that. Today, automakers use 3D printing for low-to-medium volume production parts, focusing on two goals: reducing assembly steps and cutting weight.

How it works:

- Consolidate parts: What once needed 5–6 separate parts (e.g., a sensor housing with screws, gaskets, and a cover) can now be printed as one piece. This saves assembly time and reduces the risk of failure (fewer connections = fewer things to break).

- Lightweight designs: 3D printed aluminum alloy parts (e.g., engine pistons) are lighter than cast parts but just as strong.

Famous Example: Porsche’s 911 GT2 RS uses 3D printed engine pistons. The SLM-printed pistons are 10% lighter than traditional cast pistons, and their integrated cooling channels improve engine performance by 8%. Porsche now produces these pistons in batches of 500 for its high-performance models.

Choosing the Right 3D Printing Tech & Materials for Automotive Parts

Not all 3D printing processes or materials work for every automotive application. The table below breaks down the most popular options, their best uses, and key traits.

| Automotive Component Type | 3D Printing Process | Recommended Material | Key Traits | Real-World Use Case |

|---|---|---|---|---|

| Interior (dashboard, seats) | SLA, SLS, MJF | Polymer (ABS, nylon) | Customizable, lightweight | BMW’s 3D printed dashboard trims |

| Tires, suspension parts | SLS, MJF, SLM | Aluminum alloy, polymer | Durable, shock-resistant | Michelin’s Uptis airless tires (SLS) |

| Electronic parts (sensors) | SLS, MJF | Polymer (nylon PA12) | Precision, heat-resistant | Audi’s 3D printed sensor housings |

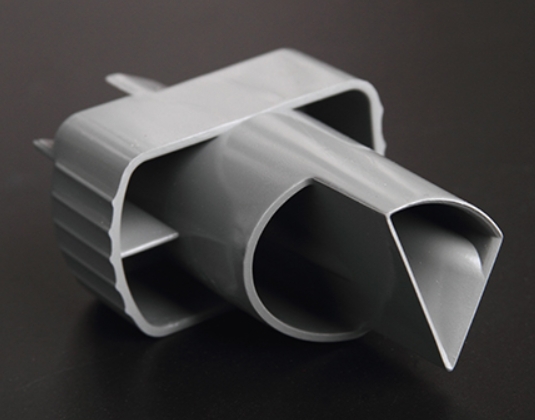

| Exhaust components | SLM | Aluminum alloy, titanium | Heat-resistant, hollow structures | Mercedes-Benz’s 3D printed exhaust vents |

| Engine parts (pistons) | SLM | Aluminum alloy (AlSi10Mg) | High strength, lightweight | Porsche’s 911 GT2 RS pistons |

| Headlights, lighting | SLA, MJF | Resin (clear) | Transparent, high detail | Ford’s 3D printed headlight prototypes |

| HVAC ducts | SLS, MJF | Nylon | Flexible, heat-resistant | Toyota’s 3D printed HVAC ducts |

Iconic Automotive 3D Printing Success Stories

Two examples stand out for showing how 3D printing can redefine automotive innovation: Michelin’s Uptis tires and Porsche’s 3D printed pistons. Let’s dive deeper into these game-changers.

1. Michelin’s Uptis: The Airless Tire (Made Possible by 3D Printing)

In 2019, Michelin unveiled the Uptis (Unique Puncture Resistant Tire System)—a tire that never goes flat. Unlike traditional tires (which rely on air pressure), the Uptis uses a 3D printed lattice structure to support the vehicle’s weight.

Why 3D printing was critical:

- The lattice design (a complex web of polymer strands) can’t be made with traditional tire manufacturing (which uses molds for solid rubber).

- 3D printing let Michelin test 20+ lattice designs in 6 months (traditional testing would have taken 2 years).

- The tire reduces waste: No more flat tires mean fewer tires end up in landfills.

Michelin plans to start equipping cars with Uptis tires by 2024, with partners like General Motors. Early tests show the tires last 2x longer than traditional tires and improve fuel efficiency by 5% (thanks to their lighter weight).

2. Porsche’s 3D Printed Pistons: Performance Meets Precision

Porsche’s 911 GT2 RS is a high-performance sports car—but its engine was limited by traditional piston design. The company turned to SLM 3D printing to create pistons that could handle higher temperatures and reduce weight.

Key improvements from 3D printing:

- Integrated cooling channels: Traditional pistons have no internal cooling (relying on oil to dissipate heat). The 3D printed pistons have tiny channels that circulate oil, keeping the piston cooler during high-speed driving.

- 10% weight reduction: Lighter pistons mean the engine can rev faster, improving acceleration.

- Better fit: SLM printing’s precision (±0.05 mm) ensures each piston fits perfectly in the engine, reducing friction.

Porsche’s tests showed the 3D printed pistons let the 911 GT2 RS’s engine produce 30 more horsepower than the traditional version—without sacrificing reliability.

Yigu Technology’s Perspective on 3D Printing in Automotive

At Yigu Technology, we see 3D printing as the automotive industry’s “flexibility engine.” For automakers, we focus on matching the right 3D process to their goals—whether it’s SLS for durable interior parts, SLM for high-strength engine components, or MJF for medium-volume spare parts. We’ve helped EV startups print custom battery brackets that cut chassis weight by 15%, and classic car shops reverse-engineer rare parts to keep vintage models on the road. We also prioritize sustainability: our 3D printing processes reduce material waste by 60% compared to traditional machining, aligning with the industry’s shift to greener manufacturing. For us, 3D printing isn’t just about making parts—it’s about helping automakers build better, more efficient, and more personalized vehicles.

FAQ About 3D Printing in the Automotive Industry

1. Can 3D printing be used for mass-produced car parts (e.g., 100,000+ units)?

Currently, no—3D printing is still too slow for very high-volume parts (like door handles or windshields) compared to traditional processes like injection molding. But it’s ideal for low-to-medium volumes (100–10,000 units), such as high-performance engine parts or custom EV components. As 3D printing speeds improve (e.g., new MJF machines that print 2x faster), this will change.

2. Are 3D printed automotive parts as strong as traditional ones?

Yes—when using the right materials and processes. For example, SLM-printed aluminum alloy pistons (like Porsche’s) are just as strong as cast pistons but lighter. Polymer parts (e.g., SLS-printed nylon brackets) are often stronger than injection-molded parts because they have no mold lines or weak points. The key is choosing the right material for the job (e.g., titanium for high-stress parts, nylon for lightweight components).

3. How much does 3D printing cost for automotive parts compared to traditional manufacturing?

It depends on volume:

- Prototypes (1–10 parts): 3D printing is 50–70% cheaper (no tooling costs).

- Low-volume production (100–1,000 parts): 3D printing is often cost-competitive (avoids expensive molds).

- High-volume production (10,000+ parts): Traditional processes (injection molding, casting) are cheaper (they scale better).

For example, a 3D printed sensor housing costs $25 per unit for 100 parts, but injection molding would cost $5 per unit for 10,000 parts (after paying $5,000 for the mold).