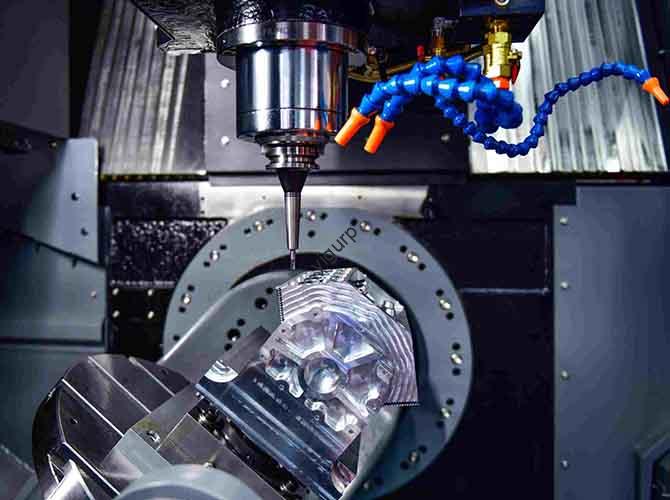

In various fields such as industrial manufacturing, art design, and auto parts processing, CNC laser cutting has become the mainstream processing method with its advantages of high precision and efficiency. However, many users will encounter problems such as “incomplete cutting”, “burrs on the edges”, and “file import errors” in actual operation, and the core reason is the lack of systematic understanding of the whole process of CNC laser cutting design. This article will break down the key points of CNC laser cutting design from basic principles to practical tips, from material selection to troubleshooting, helping you avoid common pitfalls and improve cutting quality and efficiency.

1. CNC Laser Cutting Basics: It’s never too late to figure it out

1.1 Core principles: How does laser achieve precise cutting?

The core of the laser cutting principle is to use a high-energy-density laser beam to focus on the surface of the material, causing it to melt, vaporize, or ablate quickly, while blowing the slag away from the cutting area with the help of auxiliary gas, creating a smooth incision. The applicable scenarios of different laser types vary significantly:

- CO2 laser: wavelength 10.6μm, suitable for cutting non-metallic materials (wood, acrylic, cloth) and thin metals, fast cutting speed, but large equipment volume and medium maintenance cost;

- Fiber laser: wavelength 1.06μm, stronger focusing, suitable for cutting metal materials (stainless steel, carbon steel, aluminum alloy), especially in thick plate processing, low energy consumption, simple maintenance, is the mainstream choice in the current industrial field.

Authoritative data shows that fiber lasers can cut 10mm stainless steel at a speed of 1.5-2 times faster than CO2 lasers, and the heat-affected zone of the incision is reduced by more than 30% (source: China Laser Industry Association 2024 Industry Report).

1.2 Key Systems: How do CNC control systems affect cutting accuracy?

The CNC control system is the “brain” of the laser cutting equipment, responsible for parsing design files, controlling the laser head trajectory and cutting parameters. A high-quality CNC system can achieve motion accuracy as low as 0.01mm, which directly determines the cutting accuracy and tolerance (common tolerances range from ±0.03-±0.1mm for industrial grade cutting, and up to ±0.01mm for precision machining).

Practical case: An auto parts factory once caused a batch part cutting tolerance exceedance (up to ±0.3mm) due to improper CNC system parameter settings, and subsequently optimized the system interpolation algorithm and motion speed parameters, controlling the tolerance within ±0.05mm, and the pass rate increased from 78% to 99.2%.

1.3 Basic parameters: the matching logic of cutting speed, power and material

Cutting speed and power are the core parameters that affect the cutting effect, and they need to be flexibly adjusted according to the type of material and thickness:

| Material type | Thickness (mm) | Recommended Power (W) | Cutting speed (mm/min) | remark |

| carbon steel | 3 | 500-1000 | 1500-2500 | Oxygen for auxiliary gas |

| stainless steel | 5 | 1000-2000 | 800-1200 | Nitrogen for auxiliary gases |

| Acrylic | 10 | 80-150(CO2) | 300-500 | Avoid over-melting |

1.4 Safety and maintenance: the bottom line of practical operation that cannot be ignored

Safety operation specifications are the top priority: the laser is a Class 4 hazardous light source, and professional laser protective glasses must be worn (selected according to the laser wavelength) during operation, and protective fences must be set up around the equipment, and it is strictly forbidden to look directly at the laser beam without protection; At the same time, it is necessary to regularly check the key points of equipment maintenance, such as:

- Clean the laser lenses (focusing lenses, reflectors) every week to avoid laser energy attenuation caused by lens pollution;

- Check the lubrication of the guide rail every month to prevent the wear of moving parts from affecting the accuracy;

- The laser beam focus position is calibrated quarterly to ensure that the cutting energy is concentrated.

2. Design software and file preparation: Skills for the whole process from drawing to export

2.1 Necessary tools: Selection and application of CAD/CAM software

CAD/CAM software is the core tool of CNC laser cutting design, and different software is suitable for different scenarios:

- Entry-level: AutoCAD (suitable for 2D vector drawing, supports DXF file format export, easy to operate), CorelDRAW (suitable for art decoration design, powerful graphics editing functions);

- Professional grade: SolidWorks (can directly generate 2D unfolding drawings after 3D modeling, suitable for complex part design), Mastercam (outstanding CAM function, strong cutting path optimization ability, preferred for industrial manufacturing).

Practical Tips: Beginners are recommended to start with AutoCAD, focusing on mastering the key points of vector file design, and avoid using bitmaps (such as JPG or PNG) to directly import cutting, otherwise it will lead to blurred cutting paths and reduced accuracy.

2.2 File Format and Layer Management: The key to avoiding import errors

The DXF file format is a universal format for laser cutting equipment, and it should be noted when exporting:

- Close the excess layers and keep only the contour lines needed for the cut (it is recommended to set the cut line to red and name the layer “Cut”);

- Ensure drawing closure without breakpoints, overlapping lines (verifiable by the “Check Closure” function of CAD software);

- Uniform units (mm is recommended) to avoid dimensional deviations caused by unit confusion.

Layer management and color coding can greatly improve work efficiency, such as red for outer contour cutting, blue for internal hollowing, green for perforation positions, and the machine can automatically identify the cutting sequence and parameters by color.

2.3 Path optimization and nested layout: core techniques for cost reduction

The core of cutting path optimization is to reduce the empty movement of the laser head, and the path can be planned according to the principle of “inside first, then outside, small first and then large”, for example: when cutting parts with hollows, the internal hollow pattern is cut first, and then the outer contour is cut to avoid part deformation.

Nesting techniques can effectively improve material utilization and reduce waste:

- Utilize the automatic nesting function of CAM software to closely arrange multiple parts and avoid large voids;

- For long strip parts, they can be rotated to fit the edge of the material;

- Practical case: A furniture factory improved the material utilization rate from 68% to 85% by optimizing nested typesetting, saving about 30,000 yuan in material costs per month.

2.4 File Export and Compatibility Check: The last check

After the file is exported, there are two key checks to perform:

- Compatibility check: Open the file with the control software that comes with the device to confirm that there is no missing graphics and no deviation in size;

- Parameter preview: Check whether the cutting path is smooth and whether the perforation position is reasonable to avoid “over-cutting” and “missing cutting”.

FAQ: Some users do not check “DXF R12 Compatibility Mode” when exporting files, resulting in devices not being recognized, so it is recommended to prefer to export in lower version compatibility mode.

3. Material selection and processing: the key link of adapting to laser cutting

3.1 Material classification: Differences in cutting between metals and non-metals

Metal material cutting is mainly stainless steel, carbon steel, aluminum alloy, attention should be paid to:

- Carbon steel: the higher the carbon content, the more difficult it is to cut, it is recommended to choose mild steel with a carbon content of ≤ 0.2%, the cutting edge is smoother;

- Stainless steel: high chromium content, easy to produce oxide scale, nitrogen gas needs to be used as auxiliary gas to prevent rust on the incision;

- Aluminum alloy: Strong thermal conductivity, need to increase laser power, reduce cutting speed, and avoid heat diffusion leading to melting of the cut.

Non-metallic material cutting includes acrylic, wood, fabric, plastic, etc., with the following characteristics:

- Acrylic: The edge is smooth after cutting, which can be directly used for decoration, but pay attention to ventilation to avoid harmful gases;

- Wood: Choose dry, scar-free materials, too fast cutting speed will lead to charring of the edges;

- Fabric: Laser cutting has no burrs, and the cut does not detach from the thread, which is suitable for batch processing, but the power needs to be controlled to avoid burn-through.

3.2 Material Thickness Limitations: Matching laser power with thickness

Material thickness limits for different laser powers (reference values):

| Laser Power (W) | Maximum thickness of carbon steel (mm) | Maximum thickness of stainless steel (mm) | Maximum thickness of acrylic (mm) |

| 500 | 8 | 5 | 20 |

| 1000 | 12 | 8 | 30 |

| 2000 | 20 | 15 | 50 |

Note: The actual cutting thickness is affected by factors such as the focusing mirror of the equipment and the pressure of the auxiliary gas, and it is recommended to refer to the parameter table provided by the equipment manufacturer.

3.3 Material treatment: surface treatment and heat-affected zone control

Surface treatment requirements directly affect cutting quality:

- Metal materials: Before cutting, the surface oil and rust should be removed, otherwise it will cause pores and burrs in the incision;

- Non-metallic materials: The surface of acrylic needs to be covered with a protective film to avoid scratches during cutting; the wood needs to be dried in advance to a moisture content of ≤12% to prevent deformation after cutting.

The material heat-affected zone refers to the area where the material is affected by heat during the cutting process, and the control tips are as follows:

- Reduce laser power, increase cutting speed, and reduce heat residence time;

- increase the pressure of the auxiliary gas, blow away the slag in time, and take away the heat;

- For precision parts, a “pulsed laser” mode is available to reduce heat buildup.

3.4 Special materials and environmental protection requirements

Special material precautions:

- Brass, copper: high reflectivity, high-power fiber laser (≥3000W) needs to be used, and with a special focusing mirror;

- Glass: Pulsed laser is required, and scratches should be made on the surface before cutting to avoid rupture caused by stress concentration;

- Chlorine-containing plastics (such as PVC): Toxic gases (chlorine) are produced during cutting, and laser cutting is strictly prohibited.

Environmental protection and recycling: The waste generated during the cutting process needs to be sorted and treated, metal waste can be recycled and reused, and non-metallic waste (such as acrylic, wood) needs to avoid incineration and can be crushed and recycled or harmlessly treated.

4. Process parameters and optimization: core skills to improve cutting quality

4.1 Focus Position Adjustment: The key to determining the quality of the incision

Focusing position adjustment is the core process of laser cutting, where too high a focus will lead to dispersion of cutting energy and wider cuts. Too low a focus will lead to excessive melting of the material and increased edge burrs.

Practical method:

- Calibration using the “paper sheet method”: place the paper on the surface of the cutting material, move the laser head, when the paper is penetrated by the laser and the incision is the smallest, that is, the best focus position;

- Adjust according to the thickness of the material: when cutting thin material (≤3mm), the focus can be slightly higher than the surface of the material; when cutting thick material (≥10mm), the focus should be 1-2mm deep into the material.

Case: When an electronics factory cut a 0.5mm stainless steel shell, the incision burr was serious due to improper focus position, and after adjusting the focus, the burr height was reduced from 0.15mm to less than 0.03mm, which met the product requirements.

4.2 Auxiliary gas: Tips for selecting air pressure and type

Air pressure and auxiliary gas directly affect the cutting effect, and different materials correspond to different choices:

- Oxygen: suitable for carbon steel cutting, can help combustion, improve cutting speed, but will cause oxidation of the incision, need to be polished later;

- Nitrogen: suitable for cutting stainless steel, aluminum alloy and precision parts, which can prevent oxidation of the incision and smooth edges, but the air pressure needs to be high (0.6-1.2MPa);

- Air: low cost, suitable for cutting non-metallic materials and metal materials with low requirements for incision, but pay attention to air dryness to avoid moisture affecting cutting.

Air pressure adjustment principle: the thicker the material, the higher the air pressure; the faster the cutting speed, the air pressure needs to increase accordingly.

4.3 Perforation parameters and cutting sequence: avoid material deformation

Piercing parameter setting is the key to thick material cutting: thick material needs to be perforated on the surface of the material before cutting, if the perforation power is too large and the time is too long, it will cause the material to melt locally and affect the cutting accuracy. Suggestion:

- The perforation power is 70%-80% of the cutting power;

- The perforation time is adjusted according to the material thickness (about 0.1 seconds for 1mm thick material, about 1-2 seconds for 10mm thick material);

- Uses “pulse perforation” mode to reduce thermal effects.

The cutting sequence planning should follow the principles of “symmetrical cutting” and “weak first and then strong”: for irregular parts, cut the symmetrical part first, and then cut the asymmetrical part; Cut the rigid areas first, and then the weak ones to avoid deformation of the material due to stress release.

4.4 Waste material treatment and process parameter library construction

Leftover material handling skills:

- For mass-produced parts, the residual material connection point can be reserved during nesting, and then manually separated after cutting to reduce the waste of residual material.

- The remaining material can be used for small parts processing or testing to improve material utilization.

The construction of process parameter library can greatly improve production efficiency, and it is recommended to store them according to “material type – thickness – cutting parameters”, such as:

- Material: 3mm stainless steel; Parameters: Power 1000W, Speed 1200mm/min, Air Pressure 0.8MPa, Focus – 1mm;

- Material: 10mm acrylic; Parameters: Power 120W, speed 400mm/min, air pressure 0.3MPa, focus 0mm.

By accumulating practical operation data and continuously optimizing the parameter library, the trial cutting time can be reduced and the product consistency can be improved.

5. Application Fields and Cases: Practical scenarios of CNC laser cutting design

5.1 Industrial Manufacturing: Efficiency Improvements in Mass Production

In industrial manufacturing applications, CNC laser cutting is primarily used for batch processing of automotive parts, electronic device enclosures, mechanical parts, and more. Case: An auto parts factory used a 2000W fiber laser cutting machine to replace the traditional punch machine processing engine mount, increasing production efficiency by 3 times, reducing mold costs by 80%, and increasing the product qualification rate from 92% to 99.5%.

5.2 Art and decoration: the realization path of creative design

In the field of art and decoration design, CNC laser cutting can accurately realize complex patterns, case: a decoration company designed a metal screen for a high-end hotel, using laser cutting stainless steel plate to achieve hollow patterns and curve shapes, with a cutting accuracy of 0.1mm, and the effect after installation is completely consistent with the design drawing, which is highly recognized by customers.

5.3 Architectural Models and Personalized Customization: Advantages of Small Batch Production

In the production of architectural models, laser cutting can quickly cut wood, acrylic and other materials to make fine building components; In personalized products (such as custom jewelry and souvenirs), laser cutting can be produced in single pieces or small batches without the need for molds, providing high flexibility. Case: A cultural and creative company used laser cutting technology to customize personalized metal bookmarks for customers, from design to finished product in just 24 hours, with monthly sales exceeding 5,000 pieces.

5.4 High-end field: precision processing of medical devices and electronic components

In medical device manufacturing, laser cutting is used to process precision parts such as surgical instruments and implants, requiring a cutting accuracy of ≤ 0.02mm, and the incision is free of burrs and oxidation; In electronic shell cutting, laser cutting can achieve complex heat dissipation holes and snap structures to meet the thin and light needs of electronic devices.

6. Common problems and solutions: Avoid pitfalls in practice

6.1 Incomplete cutting: causes and solutions

- Causes: insufficient laser power, too fast cutting speed, improper focus position, insufficient auxiliary gas pressure;

- Solution:

- Increase the laser power (not more than 90% of the rated power of the equipment);

- Reduce cutting speed, especially thick material cutting;

- Recalibrate the focus position;

- Check whether the auxiliary gas line is blocked and increase the air pressure.

6.2 Edge burrs: Comprehensive investigation from parameters to materials

- Causes: too low focus, wrong auxiliary gas type, impurities on the surface of the material, too slow cutting speed;

- Solution:

- Raise the focus position appropriately;

- Replace suitable auxiliary gas (e.g. nitrogen for stainless steel);

- oil stains and rust on the surface of cleaning materials;

- Increases cutting speed and reduces material melting.

6.3 Material Deformation: Stress Control and Cutting Strategy Adjustment

- Causes: stress of the material itself, improper cutting order, excessive heat-affected zone;

- Solution:

- Annealing the material before cutting to release internal stress;

- Optimize the cutting sequence and adopt symmetrical cutting;

- Reduce laser power, increase cutting speed, and reduce thermal effects;

- For thin materials, it can be fixed with a clamp while cutting to prevent deformation.

6.4 Device alarms and file errors: Quick troubleshooting techniques

- Equipment alarms: Common alarm causes include lens pollution, insufficient air pressure, and laser power failure; Solution: Clean the lens, check the gas pipeline, contact the after-sales service power supply;

- Design file errors: common problems include graphics not closing, wrong dimensions, and too many layers; Solution: Check drawing closure with CAD software, check dimensions, simplify layers.

7. FAQ: Your most concerned questions are here

- Q: What is the difference between CNC laser cutting and plasma cutting?

A: Laser cutting is more accurate (±0.03-±0.1mm vs plasma ±0.5-±1mm) and smoother cuts, suitable for thin materials and precision machining; Plasma cutting is fast and low-cost, suitable for rough processing of thick plates (≥20mm), and the cut has burrs and needs to be processed later.

- Q: Which laser cutting machine should I choose for beginners?

A: If you mainly focus on metal processing, it is recommended to choose a 1000W fiber laser cutting machine, which is suitable for most industrial scenarios; If you mainly use non-metal processing (acrylic, wood), choose an 80-150W CO2 laser cutting machine, which has a lower cost and is easy to operate.

- Q: How can I reduce material waste for laser cutting?

A: The core is to optimize nested nesting, using CAM software automatic nesting function to improve material utilization; secondly, reasonably plan the cutting path to reduce the remaining material; Finally, the leftover material is used for small parts processing or testing.

- Q: Is laser cutting equipment expensive to maintain?

A: The maintenance cost of fiber laser cutting machine is low, and the main annual cost is lens replacement (about 2000-5000 yuan) and electricity bills; CO2 laser cutting machines need to replace laser tubes regularly (about 5000-10000 yuan/year), and the maintenance cost is slightly higher.

- Q: What should I pay attention to when cutting thick material (≥15mm)?

A: Choose high-power equipment (≥2000W), use nitrogen as auxiliary gas, increase air pressure (1.0-1.2MPa), optimize perforation parameters, use pulse perforation, reduce cutting speed to ensure full energy penetration, and clean the incision slag in time after cutting.