Transparent silicone mold flipping is a specialized mold-making technique that uses high-transparency silicone materials to replicate prototypes with exceptional detail accuracy. Unlike opaque silicone, its transparency lets users monitor casting material flow, detect bubbles in real time, and verify detail replication—making it ideal for precision-critical applications like optical parts, medical devices, and decorative crafts. This article breaks down its core materials, step-by-step process, key precautions, and application scenarios—with clear comparisons and practical tips to help you achieve flawless molds and replicas.

1. Core Materials & Tools for Transparent Silicone Mold Flipping

The success of transparent silicone mold flipping depends on selecting high-quality materials that preserve transparency and detail. Below is a breakdown of essential components:

| Category | Key Items | Specifications & Selection Tips | Critical Role |

| Transparent Silicone | – Additive (Platinum-Cure) Silicone (preferred)- Condensation Silicone (budget option) | – Additive type: Low shrinkage (0.1–0.5%), high transparency (85–95% light transmittance), Shore A 20–40 (flexible for demolding).- Condensation type: Higher shrinkage (1–2%), lower transparency (70–80%), suitable for non-precision projects.- Avoid silicones with fillers (reduce transparency). | Captures prototype details (e.g., 0.05mm textures) while maintaining visibility for bubble detection. |

| Curing Agent | – Additive silicone: 1:1 ratio (by volume/weight)- Condensation silicone: 100:2–5 ratio | – Match to silicone type (never mix additive and condensation curing agents).- Use electronic scales (accuracy ±0.1g) for precise mixing—1% ratio error causes uneven curing or reduced transparency. | Triggers silicone solidification without yellowing or clouding (preserves transparency). |

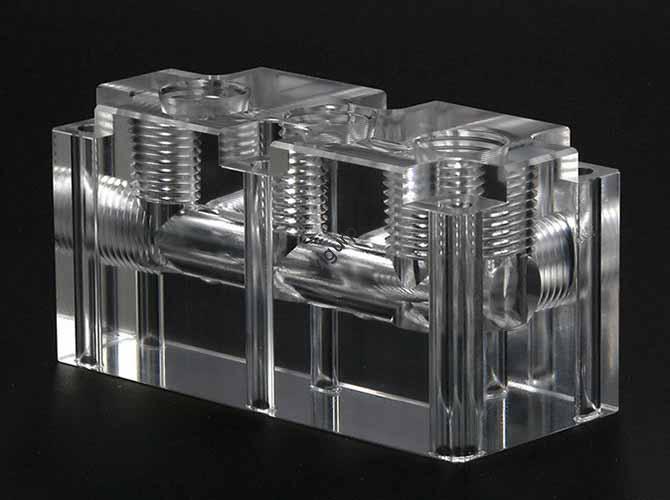

| Mold Frame Materials | – Acrylic sheets (preferred)- Plastic plates, wooden boards | – Acrylic: Transparent, lets you monitor silicone flow during pouring; thickness 3–5mm.- Wooden/plastic: Non-transparent, but cheaper; ensure flatness (±0.5mm) to avoid silicone leakage. | Holds silicone in place, defines mold shape, and (for acrylic) enables real-time flow monitoring. |

| Release Agents | – Silicone oil (100–500 cSt)- Food-grade petroleum jelly (for wax prototypes) | – Silicone oil: No residue, won’t affect transparency; apply thin layer (1–2μm).- Petroleum jelly: For wax prototypes (avoids melting); avoid excess (causes texture distortion). | Prevents silicone from sticking to the prototype, ensuring smooth demolding and intact details. |

| Auxiliary Tools | – Electronic scale (±0.1g)- Vacuum degassing machine- Stirring rods (glass/plastic)- Toothpicks (bubble removal)- Level tool | – Vacuum machine: -0.1MPa pressure, removes bubbles in 1–2 minutes (critical for transparency).- Glass stirring rods: Avoid scratching silicone (no micro-particles to reduce clarity). | Ensures precise material mixing, bubble-free silicone, and flat mold curing (avoids thickness unevenness). |

2. Step-by-Step Process of Transparent Silicone Mold Flipping

Follow this linear, detail-oriented workflow to ensure transparency, detail retention, and mold durability:

2.1 Prototype Preparation: The Foundation of Accuracy

- Clean & Smooth:

- Wipe the prototype with isopropyl alcohol (70–90%) to remove oil, dust, or 3D print residue—any impurities will be visible in the transparent mold.

- Sand 3D-printed prototypes with 400–1500 grit sandpaper (coarse to fine) to eliminate layer lines; finish with a polishing compound for a mirror-like surface.

- Defect Repair:

- Fill small cracks or gaps with transparent epoxy resin (matches silicone transparency) to avoid mold voids.

- Parting (for Complex Prototypes):

- For undercut parts (e.g., curved optical lenses), split the prototype into 2–3 sections using masking tape. Mark parting lines clearly—this ensures each mold section aligns perfectly during reassembly.

2.2 Mold Frame Setup: Ensure Flatness & Leak-Proofing

- Assemble Frame:

- Use acrylic sheets to build a frame 5–10mm taller than the prototype (ensures silicone fully covers the prototype).

- Seal frame edges with acrylic sealant (transparent, no residue) or masking tape (for temporary frames)—test for leaks by pouring 10ml of water; no leakage = ready.

- Position Prototype:

- Place the prototype in the frame center; use double-sided tape (low-tack) to fix it to the frame base.

- Use a level tool to ensure the prototype is flat (±0.1mm)—uneven positioning causes silicone thickness variation (affects transparency and strength).

2.3 Silicone Mixing & Degassing: Preserve Transparency

- Precise Mixing:

- Weigh silicone and curing agent per the ratio (e.g., 100g additive silicone + 100g curing agent).

- Stir slowly along the container wall (2–3 minutes) to avoid bubbles—fast stirring traps air, which appears as white spots in the transparent mold.

- Vacuum Degassing:

- Pour the mixture into a vacuum chamber; apply -0.1MPa pressure for 1–2 minutes. Watch for bubble formation (they rise to the surface and pop).

- Repeat degassing if bubbles remain—undegassed silicone will have visible voids, ruining transparency and detail.

2.4 Silicone Pouring & Curing: Ensure Even Coverage

- Slow Pouring:

- Tilt the frame at 45°; pour silicone slowly along the frame wall (10–15ml/s) to avoid splashing (causes bubbles).

- Use a toothpick to guide silicone into tiny prototype details (e.g., 0.1mm-wide grooves)—transparent silicone lets you verify full filling in real time.

- Bubble Removal:

- After pouring, tap the frame gently (2–3 times) to release surface bubbles; use a toothpick to pop remaining bubbles (visible through the transparent silicone).

- Controlled Curing:

- Place the frame on a flat surface in a clean, dry room (temperature 20°C–25°C, humidity 40%–60%).

- Avoid moving the frame during curing (24 hours for additive silicone, 12 hours for condensation silicone)—disturbance causes uneven transparency.

2.5 Demolding & Post-Processing: Retain Transparency

- Gentle Demolding:

- Remove the frame; apply a small amount of silicone oil to the prototype-silicone interface.

- Peel the silicone mold from the prototype at a 45° angle—transparent silicone lets you check for sticking in real time (stop and reapply oil if needed).

- Trim & Polish:

- Use a sharp knife to trim excess silicone (flash) from mold edges.

- Polish mold surfaces with 2000 grit sandpaper (light pressure) to enhance transparency—avoid over-sanding (reduces detail).

2.6 Replica Making: Use Transparency to Verify Quality

- Casting Material Selection:

- Choose transparent/translucent materials to leverage the mold’s transparency (e.g., epoxy resin for optical parts, food-grade resin for candy molds).

- Pour & Cure:

- Pour casting material into the mold (slowly, to avoid bubbles); use the mold’s transparency to check for voids.

- Cure per the material’s instructions (e.g., epoxy resin: 24 hours at 20°C).

- Demold the Replica:

- Peel the mold from the replica—transparent silicone lets you spot stuck areas early, preventing replica damage.

3. Key Precautions for Transparent Silicone Mold Flipping

Transparent silicone is more sensitive to process errors than opaque silicone—follow these rules to avoid defects:

3.1 Environmental Control

- Temperature: Maintain 20°C–25°C. Temperatures >28°C accelerate curing (traps bubbles); <18°C prolongs curing (causes cloudiness).

- Humidity: Keep <60%. High humidity (>70%) reacts with condensation silicone, turning the mold surface white (irreversible transparency loss).

- Cleanliness: Work in a dust-free room (use an air purifier). Dust particles in silicone appear as dark spots, ruining transparency.

3.2 Material Compatibility

- Never mix additive and condensation silicones—chemical reactions cause yellowing and uneven curing.

- For food-contact replicas (e.g., chocolate molds), use food-grade transparent silicone (FDA 21 CFR 177.2600 compliant) and food-safe casting materials.

3.3 Mold Maintenance

- After use, clean the mold with warm soapy water (no harsh solvents like acetone—dissolves silicone and reduces transparency).

- Dry the mold completely (air-dry for 24 hours) before storage—moisture causes mold cloudiness.

- Store in a cool, dry place (away from direct sunlight)—UV light yellows transparent silicone, reducing its service life.

4. Application Scenarios of Transparent Silicone Mold Flipping

Its transparency and detail retention make it indispensable for precision and visibility-critical projects:

| Industry/Use Case | Specific Applications | Why Transparent Silicone Is Critical |

| Optical Manufacturing | Prototypes for lenses, light diffusers, and fiber optic components. | Transparency lets engineers check for internal bubbles in the replica—critical for light transmission (bubbles cause light scattering). |

| Medical Devices | Custom molds for hearing aid shells, dental crowns, and surgical tool handles. | Visibility ensures the mold captures tiny anatomical details (e.g., tooth grooves) and no bubbles—prevents fit issues in patient use. |

| Food & Crafts | Molds for chocolate, candy, and resin art (e.g., crystal-clear keychains). | Transparency lets users monitor chocolate flow (avoids underfilling) and check for art detail intactness (e.g., embedded flowers). |

| Electronics | Replicas of transparent device parts (e.g., LED lamp covers, phone screen protectors). | Visibility verifies that the replica’s light-transmitting areas are bubble-free—ensures even light distribution in the final product. |

5. Yigu Technology’s Perspective on Transparent Silicone Mold Flipping

At Yigu Technology, we’ve seen transparent silicone mold flipping become a game-changer for clients in optical and medical fields. A common mistake we address is skipping vacuum degassing—one client tried to make a lens prototype without degassing, resulting in a mold with visible bubbles that ruined light transmission. We recommended a -0.1MPa vacuum process, which eliminated 99% of bubbles and saved them $3,000 in rework. For precision projects, we always suggest additive transparent silicone (low shrinkage) over condensation types—its 85%+ transparency ensures clients can verify details in real time. We also emphasize post-cure cleaning: using warm soapy water instead of solvents preserves transparency for 50+ mold cycles. Transparent silicone mold flipping isn’t just about replication—it’s about visibility-driven quality control, and getting the process right means avoiding costly errors.

6. FAQ: Common Questions About Transparent Silicone Mold Flipping

Q1: Why does my transparent silicone mold turn cloudy after curing?

A1: Cloudiness usually stems from three issues: (1) High humidity (>70%) during curing (reacted with condensation silicone)—use a dehumidifier. (2) Impurities in the silicone (dust, oil)—clean tools and workspace thoroughly. (3) Over-sanding during post-processing—use 2000+ grit sandpaper and light pressure. For reversible cloudiness, polish the mold with silicone oil (restores transparency).

Q2: Can I reuse a transparent silicone mold, and how many times?

A2: Yes—additive transparent silicone molds last 30–50 cycles (with proper maintenance). Condensation types last 10–20 cycles (higher shrinkage reduces reuse). To extend life: clean with warm soapy water, avoid sharp tools during demolding, and store away from UV light. Replace molds when they show yellowing, cracks, or reduced transparency.

Q3: Can I use transparent silicone mold flipping for high-temperature replicas (e.g., 150°C)?

A3: Only with high-temperature transparent silicone (service temp 200°C–300°C). Standard transparent silicone (max temp 100°C) will melt or turn opaque at 150°C. For high-heat projects (e.g., automotive light covers), choose high-temperature additive silicone and post-cure at 150°C for 1 hour to activate heat resistance. Always test a small sample first to verify transparency at high temperatures.