Steel tubing is the unsung hero of modern infrastructure and manufacturing—supporting skyscrapers, powering heavy machinery, and transporting fluids in critical systems. With so many variations available, from structural square tubing to high-pressure hydraulic options, how do you identify which type fits your project? This article breaks down the most common steel tubing types, their unique characteristics, real-world applications, and selection strategies, helping engineers, builders, and buyers make informed decisions.

1. What Are the Key Types of Structural Steel Tubing, and When to Use Them?

Structural Steel Tubing is designed for load-bearing and framework roles, with shapes tailored to distribute weight efficiently. It’s the backbone of construction, bridges, and industrial structures—here’s how its main types compare:

1.1 Square & Rectangular Steel Tubing

These tubings are defined by their sharp, uniform edges and hollow cores, making them versatile for both functional and aesthetic projects.

| Characteristic | Details |

| Shape Advantage | Flat surfaces enable seamless welding/bolting to other materials (e.g., plywood). |

| Load-Bearing Capacity | Hollow design reduces weight while maintaining strength—handles 50+ lb/sq ft. |

| Aesthetic Appeal | Sleek, minimalist look fits modern furniture and architectural trims. |

Practical Uses:

- Construction: Building frames, scaffolding, and wall studs (replaces wood to resist termites and fire).

- Bridges: Arch supports and railings (balances strength and lightness for long spans).

- Furniture: Table legs, chair frames, and shelving (combines durability with modern design).

1.2 Round Steel Tubing

Its cylindrical shape delivers uniform strength in all directions, making it ideal for high-stress load-bearing applications.

| Characteristic | Details |

| Strength Uniformity | Even load distribution reduces stress points—critical for tall structures. |

| Corrosion Resistance | Smooth surface minimizes moisture buildup; galvanization extends lifespan by 30+ years. |

| Architectural Value | Polished finish adds a modern touch to building facades and railings. |

Practical Uses:

- High-Rise Buildings: Columns and support beams (handles vertical loads from multiple floors).

- Bridges: Deck trusses and suspension components (resists wear from traffic and weather).

- Outdoor Structures: Flagpoles and light poles (galvanized variants withstand rain and UV rays).

1.3 Structural Tubing Manufacturing: Hot-Rolled vs. Cold-Rolled

The manufacturing process impacts durability and cost—choose based on your project’s precision needs:

| Process | Temperature Used | Surface Texture | Tolerance (Accuracy) | Cost | Best For |

| Hot-Rolled | Above 1000°F | Rough | Low (±0.03 inches) | Lower | Structural framing (bridges, warehouses). |

| Cold-Rolled | Room temperature | Smooth | High (±0.005 inches) | Higher | Aesthetic projects (furniture, facades). |

2. What Is Mechanical Steel Tubing, and Why Is Precision Critical?

Mechanical Steel Tubing is engineered for high-accuracy applications, where dimensional consistency and strength directly impact performance. It’s essential for machinery, automotive, and aerospace systems—here’s its key variants:

2.1 Precision Steel Tubing

Designed for tight tolerances, this tubing meets strict standards for diameter, wall thickness, and surface quality.

| Core Feature | Benefit for Practical Use |

| High Dimensional Accuracy | Fits seamlessly with other components (e.g., hydraulic valves) to reduce assembly errors. |

| Smooth Surface | Minimizes flow resistance in fluid systems (e.g., pneumatic cylinders). |

| High Pressure Resistance | Withstands 3000+ psi—ideal for machinery hydraulics. |

Practical Uses:

- Hydraulic Systems: Cylinders and hoses in excavators (maintains pressure for precise movement).

- Precision Instruments: Medical devices (e.g., MRI machines) and lab equipment (needs consistent dimensions).

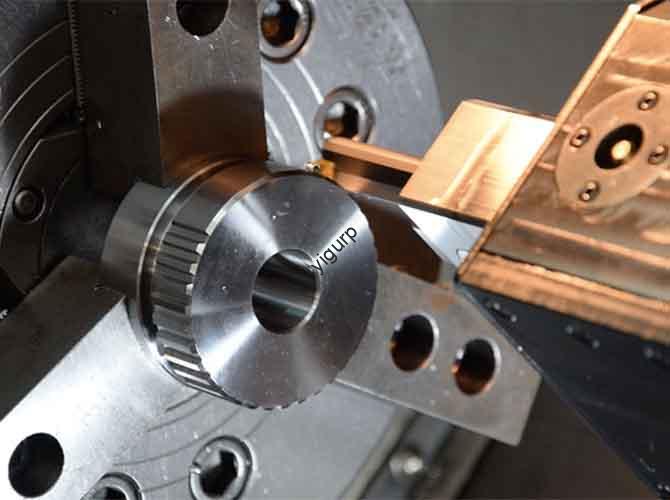

2.2 DOM (Drawn Over Mandrel) Steel Tubing

Manufactured by drawing steel over a mandrel (internal rod), DOM tubing eliminates seams for superior strength.

| Characteristic | Practical Impact |

| Seamless Construction | No weak points—resists bending and cracking in high-stress parts (e.g., drive shafts). |

| Uniform Finish | Easy to machine into custom shapes (e.g., motorcycle frames). |

| High Tensile Strength | 550+ MPa—handles vibration in industrial machinery. |

Practical Uses:

- Automotive: Drive shafts, suspension components, and steering columns (endures road stress).

- Aerospace: Hydraulic lines in aircraft (needs reliability at high altitudes).

2.3 Why Cold-Drawing Matters for Mechanical Tubing

Cold-drawing (the process for most mechanical tubing) enhances key properties through room-temperature deformation:

| Property Improved | Real-World Example of Benefit |

| Higher Strength | DOM tubing in race car frames withstands 2x more impact than hot-rolled options. |

| Better Machinability | Precision tubing for engine parts requires 30% less machining time. |

| Uniform Microstructure | Ensures consistent performance across all sections of the tubing (critical for safety parts). |

3. How Does Hydraulic Steel Tubing Perform in High-Pressure Systems?

Hydraulic Steel Tubing is built to handle extreme pressures, making it the backbone of heavy machinery and fluid transport. Its ability to resist leaks and corrosion directly impacts operational safety—here’s its key types:

3.1 High-Pressure Steel Tubing

Engineered to meet SAE standards (J524/J525), this tubing uses the Lame formula to calculate pressure ratings (allowable stress: 12,500 psi; design factor: 4:1).

| Specification | Practical Implication |

| Pressure Rating | Withstands 4x its rated capacity (e.g., 10,000 psi rated = 40,000 psi max) for dynamic loads. |

| Seamless Design | No leaks—critical for hydraulic cranes lifting 50+ tons. |

| Smooth Interior | Reduces fluid turbulence, improving machinery efficiency by 15%. |

Practical Uses:

- Heavy Machinery: Excavators, bulldozers, and forklifts (powers hydraulic arms and lifts).

- Industrial Systems: Presses and injection molding machines (needs consistent pressure for production).

3.2 Corrosion-Resistant Hydraulic Tubing

For harsh environments (e.g., marine, chemical plants), this tubing uses stainless steel (e.g., Grade 316) with 16% chromium and 3% molybdenum.

| Characteristic | Advantage for Use |

| Saltwater Resistance | Withstands pitting in offshore platforms (lasts 20+ years in saltwater). |

| Low Maintenance | No need for frequent coating—saves $5,000+/year in upkeep for marine systems. |

Practical Uses:

- Marine: Fluid lines in ships and offshore rigs (resists saltwater corrosion).

- Chemical Plants: Transport of acids and alkalis (non-reactive with harsh fluids).

4. What Are Coated Steel Tubing Types, and How Do They Protect Against Corrosion?

Coated Steel Tubing adds a protective layer to extend lifespan in outdoor or moisture-prone environments. The coating choice depends on your project’s exposure to elements—here’s the most common options:

4.1 Galvanized Steel Tubing

Coated with zinc (20–25μm thick), this tubing creates a barrier against rust and moisture.

| Coating Benefit | Practical Application Example |

| Rust Resistance | Plumbing pipes in homes (last 50+ years in indoor water systems). |

| Outdoor Durability | Fencing and handrails (withstands rain and snow in residential areas). |

| Cost-Effectiveness | 30% cheaper than stainless steel for outdoor projects. |

Practical Uses:

- Plumbing: Water supply lines (resists corrosion from chlorinated water).

- Outdoor Structures: Solar panel mounts and canopy frames (galvanized coating resists UV damage).

4.2 Powder-Coated Steel Tubing

Applied as a dry powder and cured with heat, this coating offers both protection and aesthetic appeal.

| Characteristic | Use Case Benefit |

| Scratch Resistance | Furniture frames (avoids damage from daily use). |

| Color Variety | Decorative railings in commercial buildings (matches brand aesthetics). |

| UV Resistance | Outdoor signage (no fading for 10+ years). |

Practical Uses:

- Furniture: Patio sets and office desks (combines durability with style).

- Industrial: Equipment enclosures (protects against dust and minor impacts).

5. How to Choose the Right Steel Tubing for Your Project?

Selecting the wrong tubing leads to safety risks and costly repairs. Follow this 4-step framework to match tubing to your needs:

Step 1: Define Application Requirements

- Load: For structural use (e.g., bridges), choose square/round tubing with 250+ MPa tensile strength. For high-pressure systems (e.g., hydraulics), opt for seamless high-pressure tubing.

- Precision: Machinery parts need DOM or precision tubing (±0.005 inch tolerance); structural framing can use hot-rolled (±0.03 inch).

Step 2: Assess Environmental Exposure

- Outdoor/Coastal: Galvanized or stainless steel (resists rust).

- Chemical/Marine: Grade 316 stainless steel (resists acids/saltwater).

- Indoor/Dry: Plain carbon steel (saves cost).

Step 3: Check Industry Standards

- Construction: ASTM A500 (structural tubing).

- Hydraulics: SAE J524/J525 (high-pressure tubing).

- Automotive: ASTM A106 (seamless mechanical tubing).

Step 4: Consult a Supplier for Customization

Most manufacturers (like Ansteel) offer custom cuts, coatings, or alloy blends. For example, solar panel mounts may need pre-drilled holes, while aerospace parts require specialty alloys.

Yigu Technology’s Perspective on Steel Tubing

At Yigu Technology, we supply high-quality steel tubing from Ansteel (China)—a leader in consistent, industry-compliant products. We’ve seen how the right tubing transforms projects: a construction client using our galvanized square tubing cut bridge maintenance costs by 40% vs. plain steel; an automotive manufacturer relying on our DOM tubing reduced drive shaft failures by 60%. We always advise clients to prioritize long-term value over upfront cost—galvanized or stainless steel may cost more initially, but they avoid costly replacements. For us, steel tubing isn’t just a product; it’s a solution to build reliable, efficient systems across industries.

FAQ About Steel Tubing Types and Uses

- What’s the difference between seamless and welded steel tubing?

Seamless tubing (no joints) is stronger for high-pressure applications (e.g., hydraulics), while welded tubing (made from steel sheets) is cheaper for low-stress uses (e.g., furniture). Choose seamless if your project involves pressure or heavy loads.

- Can steel tubing be customized for unique projects?

Yes—suppliers offer custom dimensions (e.g., 1–20 inch diameters), coatings (galvanized/powder-coated), and pre-drilled holes. For example, we’ve made 12-foot-long precision tubing with custom wall thickness for a medical device client.

- How long does galvanized steel tubing last outdoors?

In rural areas (low moisture/salt), it lasts 50+ years. In coastal areas (high salt), it lasts 30+ years with annual cleaning (mild soap + water). Avoid abrasives—they scratch the zinc coating and reduce corrosion resistance.