Silicone mold making is a practical manufacturing process that transforms two-component silicone materials into flexible, detail-retaining molds for replicating various objects—from handicrafts to industrial prototypes. It stands out for its simplicity, low cost, and ability to capture micro-textures (even 0.1mm details), making it popular among crafters, small businesses, and hobbyists. But what materials do you need? How to follow the process correctly? And how to fix common issues? This article answers all these questions.

1. Essential Materials & Tools for Silicone Mold Making

Choosing the right materials and tools is the first step to success. The table below lists must-have items, their functions, and selection tips:

| Category | Example Items | Function Description | Selection Tips |

| Main Materials | Two-component addition-molded silicone | The core material for mold formation; cures into elastic molds | – For food-related uses (e.g., chocolate molds): Choose FDA-certified food-grade silicone.- For industrial prototypes: Pick silicone with Shore A hardness 30–50° (balances flexibility and durability) |

| Auxiliary Tools | Electronic scale (±0.1g accuracy) | Ensures precise mixing ratio of silicone components | Avoid ordinary kitchen scales (low accuracy leads to curing failure) |

| Stirring rod (plastic/glass) | Mixes silicone main agent and curing agent evenly | Use non-metallic rods (metal may react with silicone) | |

| Measuring cup (transparent) | Holds and measures silicone; allows observation of mixing state | Choose heat-resistant cups (for accelerated curing scenarios) | |

| Master Mold Treatments | Soapy water, petroleum jelly, PVA release agent | Prevents silicone from adhering to the prototype | – For metal/glass prototypes: Use PVA release agent (strong anti-adhesion).- For resin/wood prototypes: Petroleum jelly (easy to clean) |

| Support Tools | Acrylic board/wooden frame | Builds a containment structure to fix the prototype and prevent silicone overflow | Ensure the frame is 2–3cm taller than the prototype’s highest point |

2. Step-by-Step Silicone Mold Making Process

Silicone mold making follows a linear, easy-to-follow workflow. Each step has clear requirements to avoid defects:

Step 1: Prototype Preprocessing (Lay the Foundation)

- Cleaning: Wipe the prototype (e.g., resin model, wooden craft) with a clean cloth dipped in isopropyl alcohol. Remove all oil, dust, and fingerprints—even tiny debris will create pockmarks on the mold.

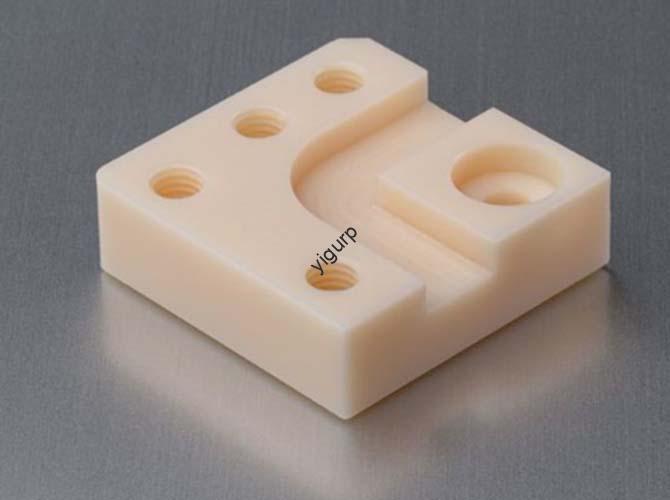

- Sanding (If Needed): For rough prototype surfaces (e.g., 3D printed parts with layer lines), sand with 400–600 grit sandpaper. This enhances silicone adhesion and improves mold smoothness.

- Splicing (For Complex Structures): If the prototype has intricate shapes (e.g., multi-part figurines), split it into blocks and mark alignment points. This makes demolding easier and reduces mold tearing.

- Release Agent Application: Apply a thin, uniform layer of release agent to the prototype. Let it dry for 5–10 minutes (avoid thick layers, which blur mold details).

Step 2: Silicone Blending (Mix for Uniformity)

- Ratio Control: Pour silicone main agent and curing agent into a measuring cup according to the manufacturer’s ratio (common ratios: 1:1 or 10:1). Use an electronic scale to weigh—e.g., 100g main agent + 10g curing agent for a 10:1 ratio.

- Mixing: Stir the mixture slowly (30–50 RPM) in one direction for 2–3 minutes. Scrape the bottom and sides of the cup repeatedly to ensure no unmixed material remains (unmixed silicone won’t cure).

- Defoaming: Let the mixed silicone stand for 5–10 minutes to release surface bubbles. For high-demand molds (e.g., jewelry molds), place the cup in a vacuum chamber (-0.1MPa) for 10–15 minutes to eliminate internal bubbles.

Step 3: Infusion Molding (Capture Details)

- Containment Setup: Place the preprocessed prototype on an acrylic board, then build a wooden/acrylic frame around it. Seal the frame’s bottom with tape to prevent silicone leakage.

- Pouring Technique: Hold the measuring cup 10–15cm above the frame and slowly pour silicone along the frame’s inner wall (not directly on the prototype). Pour at a rate of 1–2ml per second—this lets silicone flow into micro-details (e.g., texture lines) without trapping air.

- Batch Pouring (For Thick Molds): If the mold thickness exceeds 3cm, pour in 2–3 batches. Wait until the previous layer is semi-cured (surface is no longer sticky, about 2–3 hours) before adding the next layer. This reduces curing shrinkage and bubble formation.

Step 4: Curing (Set the Mold)

- Room-Temperature Curing: Place the mold in a well-ventilated area at 25°C. Initial curing takes 4–6 hours (silicone surface becomes firm), but complete curing requires 24 hours. Avoid moving the frame during curing (causes mold deformation).

- Accelerated Curing (For Urgent Needs): If you need the mold quickly, put the frame in an oven set to ≤50°C. Bake for 2–3 hours (check every 30 minutes to prevent overheating). Note: Do not exceed 50°C—high temperatures make silicone brittle.

Step 5: Demolding & Trimming (Finalize the Mold)

- Demolding: Gently peel the frame away from the silicone, then slowly lift the mold from the prototype’s edges. Use a plastic spatula to separate stuck areas—never pull hard (stretching damages the mold).

- Trimming: Cut off excess silicone (flash) around the mold with sharp scissors. For rough edges, sand with 800 grit sandpaper to ensure the mold is neat.

- Test Run: Pour a small amount of scrap material (e.g., resin, plaster) into the mold. After curing, check if the replica has clear details and no leaks. This verifies the mold’s usability before formal production.

3. Common Problems & Solutions in Silicone Mold Making

Even beginners can encounter issues during the process. The table below lists frequent problems, their causes, and practical fixes:

| Common Problem | Root Cause | Solution |

| Too Many Bubbles in the Mold | Fast pouring; insufficient defoaming; stirring too vigorously | – Pour silicone slower (≤1ml per second).- Extend vacuum defoaming time to 20 minutes.- Stir at a lower speed (30 RPM) and avoid splashing |

| Severe Mold Adhesion to Prototype | Inadequate release agent; prototype surface not cleaned | – Apply a second thin layer of release agent and dry thoroughly.- Re-clean the prototype with isopropyl alcohol to remove oil |

| Mold Tears Easily During Use | Thin mold walls (<3cm); low tear-strength silicone | – Increase mold thickness to 3–5cm.- Add a layer of fiberglass cloth to the silicone during pouring (enhances toughness)- Switch to industrial-grade silicone (tear strength >3kN/m) |

| Mold Deformation/Shrinkage | Uneven curing; single pour thickness >3cm; high ambient temperature | – Cure in a temperature-controlled room (20–25°C).- Pour in batches (each layer ≤3cm).- Add a 1–2% dimensional allowance to the prototype (offsets shrinkage) |

| Reduced Mold Lifespan | Sharp objects scratching the inner wall; improper storage | – Use plastic tools to remove replicas (avoid metal tools).- Store molds in a cool, dark place; apply a thin layer of talcum powder to prevent adhesion |

4. Application Scenarios of Silicone Molds

Silicone molds have wide uses across different fields. Here are typical application cases with specific details:

| Field | Application Examples | Mold Requirements | Key Benefits |

| Home Decoration | Tile patterns, wall reliefs, decorative candle holders | Shore A hardness 20–30° (flexible for demolding); large size (matches decoration dimensions) | Reusable (20–30 times); easy to customize patterns |

| Gourmet Creation | Chocolate sculptures, ice hockey molds, cake decorations | FDA-certified food-grade silicone; non-toxic, high-temperature resistant (up to 200°C) | Safe for food contact; easy to clean (dishwasher-friendly) |

| Industrial Prototyping | Low-volume resin product prototypes, electronic component casings | Industrial-grade silicone; high precision (±0.1mm tolerance); tear strength >4kN/m | Reduces prototyping cost (1/10 of steel molds); short production cycle (24 hours) |

| Artistic Creation | Fine reproduction of wax figures, plaster sculptures, clay crafts | Ultra-soft silicone (Shore A 10–20°); captures 0.1mm micro-details | Preserves artistic details; gentle on fragile prototypes |

5. Yigu Technology’s Perspective on Silicone Mold Making

At Yigu Technology, we believe silicone mold making is a bridge between creativity and practicality—empowering both hobbyists and small businesses. For home crafters, our 1:1 ratio addition-molded silicone simplifies mixing (no professional skills needed) and cures fully in 24 hours, ideal for candle or resin projects. For industrial clients, our high-precision industrial-grade silicone (Shore A 40–50°) achieves ±0.05mm tolerance, meeting low-volume prototype needs at 1/5 the cost of traditional molds.

We’re advancing two improvements: 1) Developing UV-curable silicone (cures in 30 minutes, cutting cycle time by 90%) for urgent projects; 2) Launching pre-cut support frames (customizable sizes) to eliminate leakage risks. Our goal is to make silicone mold making more accessible, efficient, and cost-effective for everyone.

FAQ

- How many times can a silicone mold be reused, and what affects its lifespan?

A well-made silicone mold can be reused 20–50 times. Lifespan depends on silicone type (industrial-grade lasts longer than craft-grade), usage habits (avoid sharp tools), and storage (cool, dark, dust-free environment). Applying talcum powder after cleaning also extends life.

- Can I make a silicone mold for high-temperature materials (e.g., molten wax, low-melting metals)?

Yes—but choose the right silicone. For molten wax (up to 80°C), use ordinary industrial-grade silicone. For low-melting metals (e.g., pewter, melting point 170°C), select high-temperature resistant silicone (withstands up to 200°C). Test a small mold sample first to ensure it doesn’t deform.

- What should I do if the silicone mold has uneven thickness after pouring?

First, check if the prototype is placed on a flat surface (uneven bases cause uneven silicone distribution). If pouring is complete, gently tilt the frame within 10 minutes (before silicone sets) to adjust thickness. For cured molds with slight unevenness, sand the thick areas with 600 grit sandpaper—avoid over-sanding (thins the mold too much).