Silicone duplicate molds are flexible, high-precision tools used to replicate parts with complex shapes—from 3D-printed prototypes to art sculptures. Unlike rigid molds (e.g., metal or gypsum), they leverage silicone’s elasticity to capture intricate details and simplify demolding. This article breaks down their production process, key characteristics, application scenarios, and problem-solving strategies, with clear comparisons and practical examples to help you leverage them for small-batch production, R&D, and craft projects.

1. What Are Silicone Duplicate Molds?

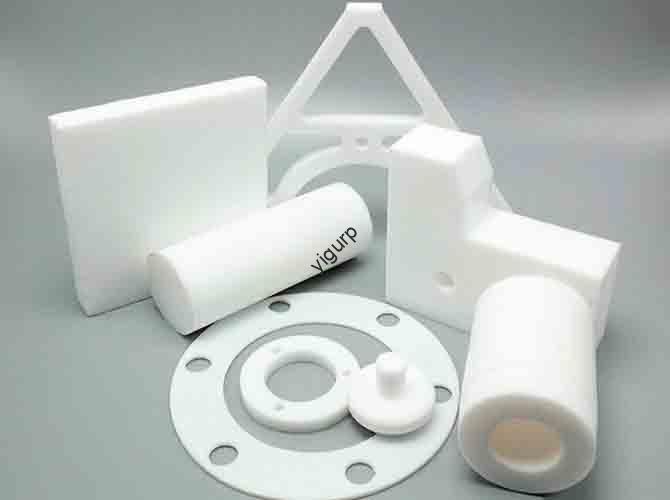

Silicone duplicate molds are specialized molds made from silicone materials (condensation or additive types) designed to reproduce physical objects with high accuracy. They act as a “negative” of the original prototype, allowing you to cast multiple copies using materials like polyurethane resin, epoxy, or gypsum.

Key Differentiators from Other Molds

| Mold Type | Material Flexibility | Detail Accuracy | Reusability | Ideal Batch Size |

| Silicone Duplicate Molds | High (elastic, easy demolding) | ±0.1mm (captures fine textures like raised text) | 20–50 cycles (durable with proper maintenance) | Small-batch (1–100 units) |

| Gypsum Molds | Low (brittle, prone to cracking) | ±0.5mm (loses fine details) | 5–10 cycles (easily damaged) | Very small-batch (1–10 units) |

| Metal Molds | Very low (rigid) | ±0.05mm (high precision but costly) | 1000+ cycles | Mass production (1000+ units) |

| Resin Molds | Medium (semi-rigid) | ±0.2mm (good but less flexible than silicone) | 10–20 cycles (prone to wear) | Small-batch (1–50 units) |

Example: A jewelry designer uses a silicone duplicate mold to replicate a hand-sculpted wax pendant—each copy retains the pendant’s tiny engravings, which a gypsum mold would blur. A car parts manufacturer, by contrast, uses metal molds for mass-produced bumpers (10,000+ units).

2. Step-by-Step Production Process of Silicone Duplicate Molds

Creating a silicone duplicate mold follows a linear, repeatable process—from prototype prep to final casting. Each step impacts the mold’s accuracy and durability.

2.1 Prototype Preparation (Foundation of Accuracy)

The prototype’s surface quality directly determines the mold’s detail. Follow these rules:

- Choose the Right Prototype: Use 3D-printed models (SLA/FFF), CNC-machined parts, hand-sculpted wax/clay, or existing finished parts.

- Smooth & Clean:

- Sand 3D-printed prototypes with 400–1500 grit sandpaper to remove layer lines.

- Wipe the prototype with isopropyl alcohol (70%–90%) to remove dust, oil, or 3D print residue. For wax prototypes, use a soft brush (alcohol dissolves wax).

- Apply Release Agent:

- Use petroleum jelly (for wax prototypes), silicone oil (for plastic/metal), or specialized mold release spray (for silicone-on-silicone replication).

- Apply a thin, even layer—thick globs distort details, while missing spots cause sticking during demolding.

2.2 Mold Frame Setup & Silicone Mixing

- Secure the Prototype:

- Place the prototype in a mold frame (plastic, wood, or metal) and use clay or tape to fix its position—ensure it’s centered and has 5–10mm of space between the prototype and frame walls (for silicone coverage).

- Select & Mix Silicone:

| Silicone Type | Mixing Ratio (Silicone:Curing Agent) | Curing Time (20°C–25°C) | Ideal For |

| Condensation Silicone | 100:2–5 | 4–8 hours | Simple shapes (e.g., basic toy parts), low-cost projects. |

| Additive Silicone | 1:1 (by volume/weight) | 2–4 hours | Complex details (e.g., art sculptures, electronic device shells), high-precision needs. |

| High-Temperature Silicone | 100:5 | 6–10 hours | Molds for high-heat casting (e.g., epoxy resin cured at 80°C–120°C). |

- Mix slowly to avoid air bubbles (use a spatula, not a whisk). For large batches, use a vacuum defoaming machine (1–2 minutes at -0.1MPa) to remove trapped air.

2.3 Silicone Pouring & Curing

- Pour Silicone:

- Tilt the mold frame at a 45° angle and pour silicone slowly along the frame wall (not directly onto the prototype)—this minimizes bubble formation.

- Fill the frame until the silicone covers the prototype by 5–10mm (too thin = fragile mold; too thick = waste of material).

- Curing:

- Room-temperature curing (20°C–25°C): Let stand undisturbed for the time listed in the table above. Avoid drafts or temperature fluctuations (slow curing and causes uneven hardness).

- Accelerated curing (for additive/high-temperature silicone): Use a thermostatic oven (50°C–60°C) to reduce curing time by 50% (e.g., 4 hours → 2 hours). Do not exceed 80°C (may damage the prototype).

2.4 Demolding & Post-Processing

- Demold Gently:

- Once cured, remove the mold frame and peel the silicone away from the prototype at a 45° angle—pulling straight up risks tearing the mold. For complex molds (e.g., parts with undercuts), split the mold into two halves before demolding.

- Trim Excess:

- Use a sharp knife or scissors to cut off silicone flash (thin, excess material along the mold edges)—this ensures clean casting later.

2.5 Casting & Replicating Parts

- Prepare Casting Material:

Choose based on your needs:

- Polyurethane Resin: Fast-curing (1–2 hours), good for functional parts (e.g., TV remote buttons).

- Epoxy Resin: High strength, heat-resistant (ideal for auto parts or electronic housings).

- Gypsum: Low-cost, for decorative items (e.g., statues, teaching models).

- Pour & Cure:

- Pour the casting material into the silicone mold (slowly, to avoid bubbles) and let it cure per the material’s instructions.

- Demold the replica once cured—silicone’s flexibility lets you remove even complex shapes without damage.

3. Key Characteristics of Silicone Duplicate Molds

Silicone duplicate molds offer unique advantages but also have limitations—understanding them helps you choose the right tool for your project.

3.1 Advantages

- High Detail Accuracy: Captures micro-details (0.1mm–0.2mm), such as the texture of a leather pattern or the raised numbers on a dial.

- Good Flexibility: Elasticity (Shore A 20–40 for soft silicone, Shore A 50–70 for hard silicone) allows easy demolding of parts with undercuts (e.g., a hook-shaped tool).

- Wide Temperature Resistance: Most silicone molds withstand -50°C to 200°C—suitable for casting materials that need high-temperature curing (e.g., epoxy resin at 120°C) or low-temperature storage.

- Reusability: With proper maintenance (cleaning, no sharp objects), a single mold can be used 20–50 times—reducing cost for small-batch production.

3.2 Limitations

- Higher Cost: Silicone is 2–3x more expensive than gypsum or resin—prohibitive for very low-budget projects (e.g., 1–2 one-off replicas).

- Longer Production Cycle: Curing silicone takes 2–10 hours (vs. 30 minutes for resin molds)—slower for urgent projects.

- Prototype Dependence: A flawed prototype (e.g., rough surface) results in a flawed mold—fixing the prototype mid-process wastes time and material.

4. Application Scenarios of Silicone Duplicate Molds

Silicone duplicate molds excel in scenarios where detail, flexibility, and small-batch production matter.

| Industry/Use Case | Specific Applications | Example |

| Product R&D & Prototyping | Replicate 3D-printed prototypes for design validation; test small batches of electronic device shells (e.g., phone cases, TV interface panels). | A tech startup uses a silicone mold to make 20 copies of a new smartwatch casing—testing fit with different watch bands before mass production. |

| Arts & Crafts | Reproduce sculptures, jewelry, custom toys, or decorative items (e.g., ceramic figurines). | A ceramic artist uses a silicone mold to replicate a hand-thrown vase—each copy retains the vase’s unique texture. |

| Automotive & Aerospace | Create small-batch custom parts (e.g., interior trim pieces, heat-resistant gaskets) or test components before metal mold production. | An auto shop uses a high-temperature silicone mold to cast 10 heat-resistant gaskets for a vintage car—cheaper than ordering a custom metal mold. |

| Education & Training | Make teaching models (e.g., anatomical parts, mechanical components) for classrooms or workshops. | A engineering school uses silicone molds to produce 50 small gear models—students assemble them to learn gear mechanics. |

5. Common Problems & Solutions for Silicone Duplicate Molds

Even with proper preparation, issues can arise—here’s how to fix them.

| Problem | Root Cause | Step-by-Step Solution |

| Bubbles in the Mold | – Fast silicone pouring (traps air).- No vacuum defoaming.- Prototype has deep crevices (air gets stuck). | 1. Pour silicone slowly along the frame wall.2. Use a vacuum defoaming machine for 1–2 minutes.3. Poke small holes in the silicone over deep crevices to release air (use a toothpick). |

| Mold Deformation | – Uneven curing (temperature fluctuations).- Prototype not fixed securely (shifts during pouring).- Silicone too thin (<5mm). | 1. Cure in a temperature-controlled room (20°C–25°C, no drafts).2. Use clay/tape to anchor the prototype firmly.3. Ensure silicone covers the prototype by 5–10mm. |

| Rough Replica Surface | – Prototype surface not sanded (has layer lines/dust).- Silicone not fully cured (tacky surface transfers to replica).- Casting material has impurities. | 1. Sand the prototype with 1500 grit sandpaper and clean with alcohol.2. Extend silicone curing time by 2–4 hours (or heat at 50°C for 1 hour).3. Strain casting material through a fine mesh sieve (100–200 mesh) before pouring. |

| Mold Sticking to Prototype | – No release agent or incompatible release agent (e.g., petroleum jelly on soft silicone).- Silicone under-cured (tacky). | 1. Apply a compatible release agent (silicone oil for plastic/metal; specialized spray for silicone).2. Cure silicone for the full recommended time (test by pressing—no stickiness = ready). |

6. Maintenance Tips to Extend Mold Life

Proper maintenance doubles or triples a silicone duplicate mold’s lifespan:

- Clean After Each Use:

- Wipe the mold with warm, soapy water (for resin/gypsum residue) or isopropyl alcohol (for oil-based casting materials). Avoid harsh solvents (e.g., acetone) that break down silicone.

- Store Correctly:

- Keep molds in a dry, dust-free container (humidity <60%, temperature 15°C–25°C). For long-term storage, dust the mold surface with talcum powder to prevent self-adhesion.

- Avoid Damage:

- Do not use sharp tools (e.g., screwdrivers) to remove stuck replicas—use a soft spatula instead.

- Do not expose molds to temperatures above their limit (e.g., 200°C for standard silicone; check the manufacturer’s specs).

7. Yigu Technology’s Perspective on Silicone Duplicate Molds

At Yigu Technology, we’ve helped hundreds of clients leverage silicone duplicate molds for R&D and small-batch production—from startups testing TV prototype shells to artists replicating sculptures. A key insight is that silicone type selection is make-or-break: For high-precision parts (e.g., electronic device interfaces), always use additive silicone (1:1 ratio) to avoid shrinkage (condensation silicone shrinks 2%–3%, blurring details). For clients on a budget, we recommend condensation silicone for simple shapes (e.g., basic toy parts) but warn against cutting corners on release agents—one client ruined a $200 prototype by skipping this step. We also emphasize vacuum defoaming for complex molds (e.g., car interior trim with undercuts)—it eliminates 90% of bubble-related defects. Silicone duplicate molds aren’t just tools—they’re cost-effective bridges between prototypes and production, but only when used with attention to detail.

8. FAQ: Common Questions About Silicone Duplicate Molds

Q1: How many times can a silicone duplicate mold be reused?

A1: It depends on the silicone type and maintenance. Standard condensation silicone lasts 20–30 cycles; additive silicone (more durable) lasts 40–50 cycles. High-temperature silicone (for industrial use) can last 50+ cycles. Proper cleaning (no harsh solvents) and storage (dry, cool) extend lifespan—neglect can reduce it to 10–15 cycles.

Q2: Can I use a silicone duplicate mold to cast metal?

A2: Only with specialized high-temperature silicone (service temperature ≥300°C). Standard silicone (max 200°C) melts when exposed to molten metal (e.g., aluminum melts at 660°C). For metal casting, use high-temperature silicone molds paired with low-melting-point alloys (e.g., tin-lead alloys, melting at 183°C–250°C). Do not use standard silicone—this causes mold failure and safety risks.

Q3: My silicone mold has a small tear—can I repair it, or do I need a new one?

A3: Small tears (<5mm) can be repaired! Clean the mold with alcohol and dry it. Mix a small amount of additive silicone (1:1 ratio) and apply it to the tear, smoothing it with a spatula. Cure for 2–4 hours (room temperature) or 1 hour at 50°C. For larger tears (>5mm) or tears in detail-critical areas (e.g., a mold for jewelry engravings), make a new mold—repairs will blur details in the replica.