If you’re wondering what precision component manufacturing is and why it matters for your industry—whether you’re in aerospace, medical devices, or automotive—let’s start with a clear answer. Precision component manufacturing is the process of creating small, intricate parts with extremely tight tolerances (often as small as ±0.001 mm) using advanced technologies and skilled craftsmanship. These components are critical because even the tiniest deviation can cause entire systems to fail, which is why industries like healthcare and aviation rely on them so heavily. In short, it’s the backbone of products that need reliability, accuracy, and consistency. Now, let’s dive deeper into how this process works, the technologies behind it, and how to choose the right partner.

Key Definitions and Core Principles of Precision Component Manufacturing

Before we get into the details, let’s make sure we’re on the same page with some basic terms. At its core, precision manufacturing is all about tolerance control—the allowable variation in a part’s dimensions. For example, a medical implant might need a tolerance of ±0.005 mm to fit correctly in the human body, while a consumer electronics part could have a slightly looser tolerance of ±0.02 mm. Another key term is repeatability, which refers to a machine’s ability to produce the same part over and over again with consistent accuracy.

The principles that guide precision component manufacturing are simple but strict: accuracy first, material suitability, and process optimization. Accuracy first means every step is designed to minimize errors, from the initial design to the final inspection. Material suitability is crucial because not all materials can handle the tight tolerances—for instance, titanium is often used in aerospace parts because it’s strong and stable under high temperatures, while medical parts might use biocompatible plastics like PEEK. Process optimization ensures that each step, from cutting to finishing, is as efficient as possible without sacrificing quality.

To put this into perspective, let’s look at a real-world example. A leading aerospace manufacturer needed a precision valve component for a jet engine. The component had to withstand temperatures of 800°C and have a tolerance of ±0.003 mm. The manufacturer chose a precision machining shop that specialized in aerospace parts, using Inconel (a heat-resistant alloy) and a 5-axis CNC machine. After 100 test runs, the shop achieved 99.8% repeatability, meeting the aerospace company’s strict requirements. This case shows how adhering to core principles ensures success in precision manufacturing.

Common Technologies Used in Precision Component Manufacturing

Precision component manufacturing relies on a range of advanced technologies, each with its own strengths and use cases. Let’s break down the most common ones, so you can understand which might be right for your project.

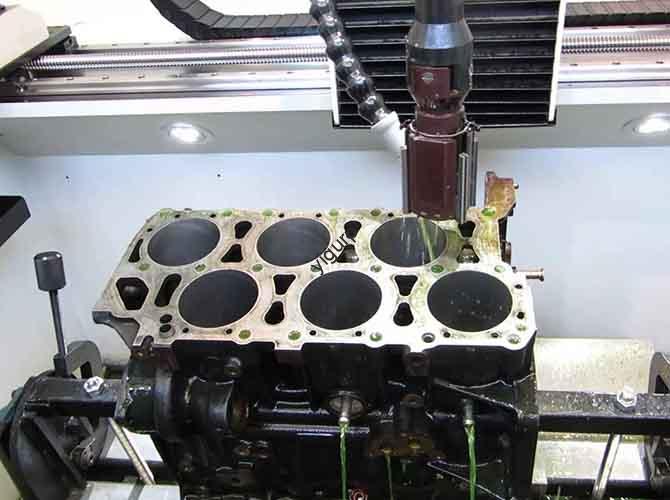

CNC Machining

CNC (Computer Numerical Control) machining is the most widely used technology in precision manufacturing. It uses computer programs to control machines like mills, lathes, and routers, allowing for extremely accurate cuts. There are several types of CNC machines, including 3-axis, 4-axis, and 5-axis models. 5-axis machines are the most versatile, as they can move the part in five different directions, making them ideal for complex parts like turbine blades.

One of the biggest advantages of CNC machining is its high repeatability—once a program is set up, the machine can produce hundreds or thousands of identical parts. It’s also suitable for a wide range of materials, from metals like aluminum and steel to plastics and composites. For example, a medical device company used a 5-axis CNC machine to produce 1,000 surgical drill bits, each with a tolerance of ±0.002 mm. The machine completed the job in half the time it would have taken with traditional methods, and every bit passed inspection.

Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, is a newer technology that’s gaining popularity in precision manufacturing. Unlike CNC machining, which removes material to create a part (subtractive manufacturing), 3D printing builds parts layer by layer using materials like plastic, metal, or ceramic. This makes it ideal for creating complex geometries that would be impossible with traditional methods, such as lattice structures in medical implants.

While 3D printing was once known for lower accuracy, recent advances have made it suitable for precision parts. For example, some industrial 3D printers can achieve tolerances of ±0.05 mm, which is enough for many consumer electronics and automotive parts. A great example is a startup that used metal 3D printing to create lightweight, precision gears for electric vehicles. The gears were 30% lighter than traditional gears and had a tolerance of ±0.03 mm, improving the vehicle’s efficiency.

Electrical Discharge Machining (EDM)

EDM is a precision machining process that uses electrical sparks to remove material from a workpiece. It’s particularly useful for hard materials like tungsten and carbide, which are difficult to cut with CNC machines. There are two main types of EDM: wire EDM and sinker EDM. Wire EDM uses a thin wire to cut through the material, making it ideal for intricate shapes like dies and molds. Sinker EDM uses a shaped electrode to create cavities in the workpiece, which is useful for making parts like injection molds.

EDM is known for its high accuracy—it can achieve tolerances of ±0.001 mm, making it a top choice for industries like aerospace and defense. For instance, a defense contractor used wire EDM to create a precision sensor housing for a missile. The housing had to fit a complex circuit board and withstand high impact, so the contractor chose EDM for its ability to cut tight corners and thin walls. The final part had a tolerance of ±0.0005 mm, meeting the military’s strict standards.

The table below compares these three key technologies to help you choose the right one for your project:

| Technology | Tolerance Range | Best For | Materials Suitable | Speed |

| CNC Machining | ±0.001 – ±0.02 mm | Complex parts with tight tolerances | Metals, plastics, composites | Fast for high-volume |

| Additive Manufacturing | ±0.05 – ±0.1 mm | Complex geometries, low-volume runs | Plastics, metals, ceramics | Slow for high-volume |

| EDM | ±0.0005 – ±0.005 mm | Hard materials, intricate shapes | Tungsten, carbide, steel | Medium |

Industries That Rely on Precision Component Manufacturing

Precision component manufacturing isn’t just for one industry—it’s a critical part of many sectors where accuracy and reliability are non-negotiable. Let’s explore the top industries that depend on these components and why.

Aerospace and Defense

The aerospace and defense industry is one of the biggest users of precision components. Planes, missiles, and satellites have thousands of small parts that need to work together perfectly, even in extreme conditions like high altitudes and temperatures. For example, a jet engine has over 20,000 components, including turbine blades and fuel nozzles, each with tolerances as tight as ±0.003 mm. If a single blade is even slightly off, it could cause the engine to fail, leading to catastrophic consequences.

According to the Aerospace Industries Association (AIA), the global aerospace industry spent over $80 billion on precision components in 2024. This includes parts for commercial aircraft, military jets, and space exploration vehicles. One notable project is NASA’s Artemis program, which uses precision components made from titanium and Inconel for the Orion spacecraft. These components must withstand the intense heat of reentry into Earth’s atmosphere (over 2,700°C) and have tolerances of ±0.002 mm to ensure a safe landing.

Medical Devices

The medical device industry relies on precision components to create life-saving products like pacemakers, surgical tools, and implants. These parts need to be not only accurate but also biocompatible (safe for use in the human body) and sterile. For example, a pacemaker has a tiny battery compartment that must be sealed to prevent fluid from entering, with a tolerance of ±0.001 mm. If the seal is even slightly imperfect, it could cause the pacemaker to fail, putting the patient’s life at risk.

A study by Grand View Research found that the global medical precision components market is expected to reach $45 billion by 2030, growing at a CAGR of 7.2%. This growth is driven by the increasing demand for minimally invasive surgeries and personalized medicine. For instance, a medical device company developed a custom hip implant using 3D printing and CNC machining. The implant was designed to fit the patient’s unique anatomy, with a tolerance of ±0.005 mm, reducing the risk of rejection and improving recovery time.

Automotive

The automotive industry, especially the electric vehicle (EV) sector, is increasingly using precision components to improve performance and efficiency. EVs have more complex electrical systems than traditional cars, requiring parts like battery connectors, motor windings, and sensor housings with tight tolerances. For example, an EV battery connector must have a tolerance of ±0.01 mm to ensure a secure connection and prevent overheating, which could lead to a fire.

According to Statista, the global automotive precision components market was valued at $68 billion in 2024, with EVs accounting for 35% of that growth. A major automaker recently switched to using precision-machined aluminum parts for its EV chassis, reducing the weight of the vehicle by 15% and improving its range by 20%. The parts had a tolerance of ±0.008 mm, ensuring a perfect fit and reducing vibration during driving.

How to Choose a Reliable Precision Component Manufacturer

Choosing the right precision component manufacturer is crucial—your choice will directly impact the quality, cost, and timeline of your project. Here are the key factors to consider, along with practical tips to help you make an informed decision.

Check Their Experience and Specialization

First, look for a manufacturer with experience in your industry. Different industries have different requirements—for example, a manufacturer that specializes in medical parts will have the necessary certifications (like ISO 13485) and knowledge of biocompatible materials, while an aerospace specialist will understand the strict standards of organizations like NASA and the FAA.

Ask for case studies or references from clients in your industry. For example, if you’re in the medical device sector, ask the manufacturer to share a case study of a surgical tool they produced. Did they meet the required tolerances? Were they able to handle the biocompatibility requirements? A reliable manufacturer will be happy to provide this information.

Evaluate Their Quality Control Processes

Quality control (QC) is everything in precision manufacturing. A good manufacturer will have a robust QC process in place to ensure every part meets your specifications. Ask about their inspection methods—do they use advanced tools like coordinate measuring machines (CMMs) or optical comparators? CMMs are highly accurate devices that can measure parts in 3D, with a tolerance of ±0.0001 mm, making them ideal for checking precision components.

Also, ask about their defect rate. A top-tier manufacturer should have a defect rate of less than 0.1%, meaning fewer than 1 out of 1,000 parts will fail inspection. For example, a precision machining shop we worked with had a defect rate of 0.05% for their aerospace parts, which is well below the industry average of 0.5%. They achieved this by implementing a 3-step QC process: initial inspection of raw materials, in-process checks during manufacturing, and final inspection before shipping.

Consider Their Technology and Capabilities

Make sure the manufacturer has the right technology to handle your project. If you need a complex part with tight tolerances, look for a shop with 5-axis CNC machines or EDM capabilities. If you’re interested in 3D printing, ask about the types of printers they use and the materials they can work with.

Also, consider their production capacity. Can they handle your volume needs? If you need 10,000 parts per month, a small shop with only one CNC machine might not be able to keep up. On the other hand, a large manufacturer might have longer lead times for small orders. Find a balance between capacity and flexibility.

Compare Costs and Lead Times

While cost shouldn’t be the only factor, it’s important to get quotes from multiple manufacturers to ensure you’re getting a fair price. Keep in mind that cheaper isn’t always better—if a manufacturer’s price is significantly lower than others, they might be cutting corners on quality or using inferior materials.

Lead times are also crucial, especially if you have a tight deadline. Ask each manufacturer how long it will take to produce your parts, including design, prototyping, and production. A reliable manufacturer will be able to give you a realistic timeline and stick to it.

Future Trends in Precision Component Manufacturing

The precision component manufacturing industry is constantly evolving, driven by advances in technology and changing market demands. Here are the top trends to watch for in the coming years.

Industry 4.0 and Smart Manufacturing

Industry 4.0, or the fourth industrial revolution, is transforming precision manufacturing by integrating digital technologies like the Internet of Things (IoT), artificial intelligence (AI), and big data. Smart factories use IoT sensors to monitor machines in real time, collecting data on temperature, vibration, and performance. This data is then analyzed by AI algorithms to predict maintenance needs, optimize production processes, and reduce errors.

For example, a precision machining shop in Germany implemented a smart manufacturing system that uses IoT sensors to track the performance of its CNC machines. The system detected a slight increase in vibration in one machine, which indicated a worn bearing. The AI algorithm predicted that the bearing would fail in 10 days, allowing the shop to replace it during a scheduled maintenance window, avoiding unplanned downtime. This reduced the shop’s downtime by 30% and improved its overall efficiency.

Increased Use of Sustainable Materials

As sustainability becomes a top priority for businesses and consumers, the precision manufacturing industry is shifting toward using more eco-friendly materials. This includes recycled metals, bioplastics, and renewable composites. For example, a consumer electronics company started using recycled aluminum for its precision smartphone components, reducing its carbon footprint by 25%. Another company developed a bioplastic made from corn starch for use in medical implants, which is biodegradable and reduces waste.

According to McKinsey & Company, the use of sustainable materials in precision manufacturing is expected to grow by 15% per year through 2030. This trend is being driven by government regulations (like carbon taxes) and consumer demand for eco-friendly products. Manufacturers that adopt sustainable practices will not only reduce their environmental impact but also gain a competitive edge in the market.

Advancements in Miniaturization

As products become smaller and more complex—think wearable devices, microchips, and medical sensors—there’s a growing demand for even smaller precision components. This is driving advancements in miniaturization technologies, such as micro-CNC machining and micro-EDM. These technologies can produce parts as small as 0.1 mm, with tolerances of ±0.0001 mm.

For example, a tech company developed a micro-sensor for a smartwatch using micro-CNC machining. The sensor is just 0.5 mm in diameter and can measure heart rate and blood oxygen levels with high accuracy. Another example is a medical device company that created a micro-pump for drug delivery systems, which is small enough to fit inside a pill and can deliver precise doses of medication to the body.

Yigu Technology’s Perspective on Precision Component Manufacturing

At Yigu Technology, we believe precision component manufacturing is the foundation of innovation in key industries. Over the years, we’ve seen how accurate, reliable components drive progress—from making medical devices safer to improving the efficiency of electric vehicles. We prioritize a customer-centric approach, working closely with clients to understand their unique needs and deliver tailored solutions. Our investment in advanced technologies like 5-axis CNC machining and smart manufacturing systems ensures we meet the tightest tolerances while maintaining efficiency. We also recognize the importance of sustainability, so we’re gradually integrating recycled materials and eco-friendly processes into our operations. For us, precision isn’t just about numbers—it’s about building trust with our clients by consistently delivering parts that exceed their expectations.

FAQ About Precision Component Manufacturing

1. What is the typical tolerance range for precision components?

The tolerance range depends on the industry and application, but most precision components have tolerances between ±0.0005 mm and ±0.02 mm. For example, aerospace parts often have tolerances of ±0.003 mm, while medical implants can be as tight as ±0.001 mm.

2. How long does it take to produce precision components?

Lead times vary based on the complexity of the part, the technology used, and the volume. A simple CNC-machined part might take 1–2 weeks, while a complex 3D-printed or EDM part could take 3–4 weeks. High-volume orders (10,000+ parts) may take 4–6 weeks, depending on the manufacturer’s capacity.

3. What materials are commonly used in precision component manufacturing?

The most common materials include metals (aluminum, steel, titanium, Inconel), plastics (PEEK, ABS, nylon), and composites (carbon fiber, fiberglass). The choice of material depends on the application—for example, titanium is used in aerospace for its strength and heat resistance, while PEEK is used in medical devices for its biocompatibility.

4. How do I ensure the precision components I order meet my specifications?

Choose a manufacturer with a robust quality control process, including inspection tools like CMMs and optical comparators. Ask for a sample part before placing a large order, and request a detailed inspection report for each batch. Also, make sure the manufacturer has certifications relevant to your industry (like ISO 9001 for general manufacturing or ISO 13485 for medical devices).

5. Is 3D printing a good option for precision components?

Yes, but it depends on your tolerance requirements. Recent advances in 3D printing have made it suitable for precision parts with tolerances of ±0.05 mm to ±0.1 mm, which is enough for many consumer electronics and automotive applications. For tighter tolerances (±0.00