Making acrylic prototypes is a specialized manufacturing process that transforms acrylic sheets (plexiglass) into physical models to validate product design, appearance, and functionality. Acrylic’s high transparency, rigidity, and ease of processing make it ideal for prototypes in industries like consumer electronics, furniture, and display products. Unlike other materials (e.g., ABS plastic), acrylic prototypes excel at simulating glass-like aesthetics while offering better impact resistance. This article breaks down the step-by-step workflow, material/tool selection, safety precautions, and real-world applications to help teams create high-quality acrylic prototypes.

1. What Are the Core Objectives of Making Acrylic Prototypes?

Every stage of the process serves specific goals that ensure the prototype aligns with design requirements and production feasibility.

| Objective | Description | Real-World Example |

| Appearance Validation | Confirm if the prototype’s transparency, color, and surface finish match the final product’s visual standards. | Testing if a transparent acrylic phone stand prototype has 90%+ light transmittance (no cloudiness) and a smooth, scratch-free surface. |

| Structural Feasibility Check | Verify if the acrylic prototype’s thickness, chamfers, and hole positions can withstand real-world use (e.g., load-bearing, assembly). | Checking if a 3mm-thick acrylic shelf prototype supports 5kg of weight without bending or cracking. |

| Assembly Compatibility Testing | Ensure the prototype fits with other components (e.g., metal brackets, plastic parts) in the final product. | Testing if an acrylic display case prototype’s hinge holes (diameter: 5mm ±0.1mm) align with metal hinge pins for smooth opening/closing. |

| Material Performance Verification | Evaluate if acrylic meets the product’s functional needs (e.g., chemical resistance, heat stability). | Confirming a food-grade acrylic container prototype resists staining from coffee or oil and doesn’t warp at 60°C (typical kitchen temperatures). |

2. What Is the Step-by-Step Workflow for Making Acrylic Prototypes?

The process follows a linear, detail-driven sequence—each step builds on the previous one to avoid defects and ensure precision.

2.1 Step 1: Preliminary Preparation (Lay the Foundation)

Proper preparation reduces rework and ensures consistency in later stages.

2.1.1 Design Drawing & File Preparation

- 3D Modeling: Use professional software like SolidWorks, UG, or Pro/E to create a detailed 3D model. Key design elements to include:

- Dimensions: Specify length, width, height (e.g., 200mm×150mm×5mm for a phone stand).

- Details: Add chamfers (≥0.5mm to avoid sharp edges), hole positions (diameter, depth), and cutouts.

- Tolerances: Set precision standards (±0.1mm for critical features like holes; ±0.2mm for non-critical edges).

- File Conversion: Export the 3D model to STL format (for CNC/laser cutting) or 2D DWG/DXF format (for manual cutting) to ensure compatibility with processing equipment.

2.1.2 Material Selection Guide

Choose acrylic sheets based on the prototype’s purpose, appearance, and performance needs.

| Acrylic Type | Key Properties | Ideal Applications |

| Transparent Acrylic | High light transmittance (90%–92%), clear like glass. | Display cases, phone stands, light covers, or prototypes needing visibility (e.g., a clear storage box). |

| Colored Acrylic | Opaque or translucent (available in red, blue, black, etc.), consistent color throughout. | Decorative prototypes (e.g., colored furniture panels, branded signage). |

| Thick Acrylic (10mm–20mm) | High rigidity and load-bearing capacity. | Structural parts (e.g., acrylic shelves, table tops, or heavy-duty display stands). |

| Thin Acrylic (1mm–5mm) | Lightweight, easy to bend (with heat), and cost-effective. | Thin-walled prototypes (e.g., phone case inserts, flexible display frames). |

| Specialty Acrylic | – Impact-Resistant Acrylic: 5x stronger than standard acrylic (for durable prototypes like protective covers).- Food-Grade Acrylic: Non-toxic, suitable for kitchen/medical prototypes (e.g., food storage containers). | Protective gear, food-contact products, medical device housings. |

2.1.3 Tool & Equipment Preparation

Gather tools based on the cutting method (manual vs. automated) and post-processing needs.

| Tool Category | Manual Cutting (Small/ Simple Prototypes) | Automated Cutting (Complex/Large Prototypes) | Purpose |

| Cutting Tools | – Utility knife (with thin, sharp blades)- Acrylic-specific hand saw (fine teeth: 18–24 TPI)- Ruler/straightedge (for guiding cuts) | – CNC Engraving Machine: For precise, complex shapes (e.g., curved edges, multiple holes).- Laser Cutting Machine: Uses high-energy laser beams for clean, burr-free cuts (ideal for thin acrylic: 1mm–5mm). | Cut acrylic sheets to the desired shape. |

| Sanding Tools | – Sandpaper (80–2000 mesh: coarse to fine)- Sanding block (for even pressure) | – Orbital sander (with sanding pads: 80–2000 mesh)- Polishing machine (for high-gloss finishes) | Smooth rough edges and surfaces after cutting. |

| Drilling Tools | – Hand drill (variable speed)- Acrylic-specific drill bits (high-speed steel or carbide, sharpened for plastic) | – CNC drill press (for precise hole positioning and depth control) | Create holes for assembly (e.g., hinge pins, screws). |

| Bonding Tools | – Acrylic-specific glue (solvent-based: trichloromethane/chloroform, or water-based acrylic adhesive)- Clamps (spring clamps, C-clamps) to hold parts in place- Cotton swabs (for applying glue evenly) | – Automated glue dispensing machine (for consistent glue application in batch production) | Bond multiple acrylic components (e.g., attaching a shelf to a frame). |

| Safety Gear | – Protective glasses (to prevent acrylic shards from eye injury)- Gloves (chemical-resistant for handling glue)- Dust mask (for sanding dust) | – Safety enclosure (for laser/CNC machines)- Ventilation system (to remove fumes from glue or laser cutting) | Protect workers during cutting, sanding, and bonding. |

2.2 Step 2: Processing & Production (Shape the Acrylic)

This stage transforms raw acrylic sheets into the prototype’s basic form through cutting, drilling, and bonding.

2.2.1 Cutting: Manual vs. Automated Methods

Choose the cutting method based on prototype complexity, quantity, and precision needs.

| Method | Step-by-Step Process | Pros | Cons | Example Use Case |

| Manual Cutting | 1. Mark the cutting line on the acrylic sheet using a marker and ruler.2. Secure the sheet to a flat workbench with clamps.3. For straight cuts: Use a utility knife to score the line 5–10 times (apply even pressure), then snap the sheet along the scored line.4. For curved cuts: Use a hand saw to make slow, steady cuts (follow the marked curve). | – Low cost (no expensive equipment).- Fast setup (minutes to start).- Ideal for small, simple prototypes (1–2 units). | – Low precision (±0.5mm tolerance).- Risk of uneven edges or cracking (if pressure is too high).- Not suitable for complex shapes (e.g., intricate cutouts). | Cutting a simple rectangular acrylic phone stand (200mm×150mm×5mm) with straight edges. |

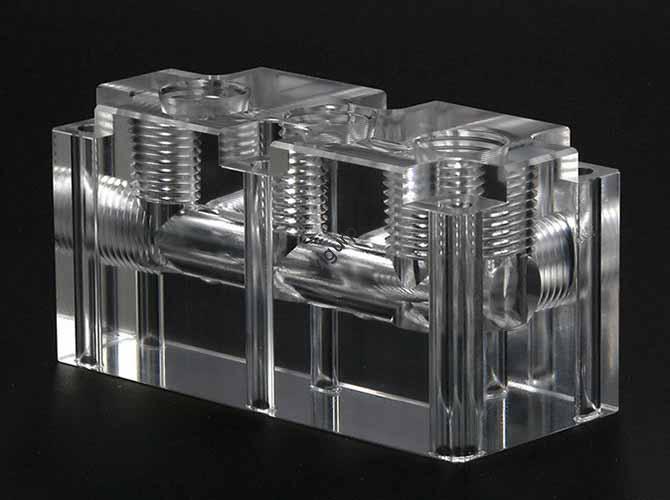

| CNC/Laser Cutting | 1. Import the STL/DXF file into the machine’s control software.2. Set cutting parameters: – CNC: Spindle speed (10,000–15,000 RPM), feed rate (50–100mm/min), tool type (end mill for acrylic). – Laser: Power (30–50W for 1mm–5mm acrylic), speed (100–300mm/min), focus distance.3. Secure the acrylic sheet to the machine bed (use double-sided tape or a vacuum chuck).4. Start the machine—let it cut automatically (no manual intervention needed). | – High precision (±0.05mm–±0.1mm tolerance).- Clean, burr-free edges (no sanding needed for laser cuts).- Suitable for complex shapes (e.g., curved cutouts, multiple holes) and batches (10+ units). | – High equipment cost (CNC/laser machines: \(10k–\)50k).- Longer setup time (1–2 hours for file calibration). | Cutting a complex acrylic display case with curved edges, multiple holes, and a decorative cutout pattern. |

2.2.2 Sanding: Achieve Smooth Surfaces

Sanding removes burrs, scratches, and uneven edges from cut acrylic—critical for appearance and safety.

- Coarse Sanding (80–120 Mesh):

- Use 80-mesh sandpaper to remove large burrs from cutting (e.g., rough edges from manual sawing).

- Hold the sandpaper perpendicular to the acrylic surface and apply even pressure—avoid circular motions (which cause uneven sanding).

- Medium Sanding (240–400 Mesh):

- Switch to 240–400 mesh sandpaper to smooth out scratches from coarse sanding.

- For curved edges, wrap sandpaper around a sanding block to maintain the curve shape.

- Fine Sanding (800–2000 Mesh):

- Use 800–1200 mesh sandpaper for a near-smooth finish, then 1500–2000 mesh for a polished look (critical for transparent acrylic).

- Wipe the surface with a damp cloth between sanding stages to remove dust and check progress.

2.2.3 Drilling (If Holes Are Required)

Follow these steps to drill holes without cracking the acrylic (a common issue with brittle materials).

- Mark the Hole Position:

- Use a center punch to create a small indentation at the hole’s center—this prevents the drill bit from slipping.

- Double-check the position against the design drawing (e.g., 20mm from the edge for a hinge hole).

- Choose the Right Drill Bit:

- Use acrylic-specific drill bits (sharpened with a 60° angle) or high-speed steel (HSS) bits. Avoid wood/metal bits (they cause melting or cracking).

- Set Up the Drill:

- Adjust the drill speed to low–medium (1000–1500 RPM)—high speed generates heat, which melts acrylic.

- Secure the acrylic sheet to a workbench (use clamps) and place a scrap piece of wood under the hole area (prevents the acrylic from chipping when the drill exits).

- Drill Carefully:

- Apply light, steady pressure—let the drill bit do the work (too much pressure cracks the acrylic).

- Pause periodically to cool the drill bit with water (reduces heat buildup).

2.2.4 Bonding (For Multi-Component Prototypes)

Bonding joins multiple acrylic parts into a single prototype—use acrylic-specific glue for strong, clear bonds.

- Prepare the Surfaces:

- Clean the bonding surfaces with isopropyl alcohol to remove oil, dust, or sanding residue (dirty surfaces weaken the bond).

- Ensure the surfaces are flat and aligned (use a ruler to check—misaligned parts cause gaps).

- Apply Glue:

- For small parts: Use a cotton swab to apply a thin, even layer of solvent-based glue (trichloromethane) to one surface—avoid excess glue (it causes cloudiness).

- For large parts: Use a glue syringe to apply glue along the edge (1–2mm bead) for consistent coverage.

- Clamp and Cure:

- Press the parts together firmly and secure them with clamps (spring clamps for small parts; C-clamps for large parts).

- Let the glue cure at room temperature (25°C–30°C) for 4–24 hours (solvent-based glue takes longer to cure than water-based glue).

- Do not move the parts during curing—this disrupts the bond.

2.3 Step 3: Post-Processing (Refine the Prototype)

Post-processing enhances the prototype’s appearance, functionality, and durability.

2.3.1 Polishing (Optional: For High-Gloss Finishes)

Polishing is recommended for transparent or decorative prototypes to achieve a glass-like shine.

| Polishing Method | Process | Best For |

| Manual Polishing | 1. Apply a small amount of acrylic polishing paste (containing cerium oxide) to the surface.2. Use a soft, clean cloth to polish in circular motions (apply light pressure) for 5–10 minutes.3. Wipe off excess paste with a damp cloth and buff with a dry cloth for a final shine. | Small prototypes (e.g., phone stands, small display cases) or hard-to-reach areas (curved edges). |

| Machine Polishing | 1. Attach a soft polishing wheel (cotton or felt) to a low-speed polisher (1000–1500 RPM).2. Apply polishing paste to the wheel and gently touch it to the acrylic surface.3. Polish in a back-and-forth motion (follow the grain from sanding) until the surface is glossy. | Large prototypes (e.g., acrylic shelves, table tops) or batch production. |

2.3.2 Cleaning & Final Inspection

- Cleaning: Wipe the prototype with clean water or a mild detergent to remove glue residue, polishing paste, or dust. For stubborn residue, use a soft brush (avoid abrasive sponges, which scratch acrylic).

- Drying: Pat the prototype dry with a lint-free cloth (microfiber cloths work best) to prevent water spots.

- Final Inspection: Check for defects using this checklist:

- Appearance: No scratches, cloudiness, or glue residue; transparent parts have 90%+ light transmittance.

- Dimensions: Use digital calipers to verify key dimensions (e.g., hole diameter: 5mm ±0.1mm; length: 200mm ±0.2mm).

- Structural Integrity: Test bonds (gently pull parts—no separation) and load-bearing capacity (e.g., place 5kg on a shelf prototype—no bending).

- Safety: Ensure all edges are chamfered (no sharpness) and no small parts pose choking hazards (for consumer products).

3. What Are the Critical Safety Precautions?

Acrylic processing involves sharp tools, toxic glue, and heat—follow these rules to avoid injury and defects.

3.1 Cutting & Drilling Safety

- Wear Protective Gear: Always use protective glasses (prevents acrylic shards from entering the eyes) and gloves (avoids cuts from sharp edges).

- Secure the Acrylic: Never hold the sheet by hand while cutting/drilling—use clamps to fix it to a workbench (prevents slipping and accidents).

- Laser Cutting Ventilation: If using a laser cutter, ensure the workspace has a ventilation system (laser cutting acrylic releases fumes that irritate the lungs).

3.2 Glue Safety

- Use in a Well-Ventilated Area: Solvent-based glues (e.g., trichloromethane) emit toxic fumes—work near an open window or use a fume hood.

- Avoid Skin Contact: Wear chemical-resistant gloves (nitrile or latex) when handling glue—direct contact causes skin irritation.

- Store Glue Properly: Keep glue in a sealed container away from heat and flames (solvent-based glue is flammable).

3.3 Material Handling Safety

- Prevent Cracking: Acrylic is brittle—avoid dropping or bending thick sheets (they break easily). For thin sheets, roll them (don’t fold) for storage.

- Avoid Heat Exposure: Acrylic softens at 80°C–100°C—keep prototypes away from heaters, direct sunlight, or hot surfaces (prevents warping).

4. What Is a Real-World Example: Transparent Acrylic Phone Stand Prototype?

Let’s apply the workflow to a common consumer prototype: a 200mm×150mm×5mm transparent acrylic phone stand.

- Preliminary Preparation:

- Design: Create a 3D model with a 15° angle (for phone support), 2mm chamfers on all edges, and two 5mm holes (for cable management).