Die casting for accessories has become a backbone of modern manufacturing, enabling the efficient production of high-precision, complex metal parts across industries. By injecting molten metals into custom molds under high pressure, this technology balances speed, quality, and cost—addressing the demands of both large-scale production and custom accessory needs. This article breaks down its core mechanics, material choices, key processes, and real-world applications to help you leverage it effectively for accessory manufacturing.

1. Core Basics: Definition & Unmatched Advantages

To understand why die casting dominates accessory production, start with its fundamental traits. Below is a 总分结构 breakdown of its definition and key benefits:

1.1 What Is Die Casting for Accessories?

Die casting for accessories is a metal forming process that involves:

- Melting metals (or their alloys) into a liquid state.

- Injecting the molten material into a precise, custom-designed mold (typically made of H13 hot-work steel) at high pressure (5–150 MPa) and speed (0.5–5 m/s).

- Allowing the metal to rapidly solidify (10–60 seconds, depending on part size) under sustained pressure.

- Ejecting the finished accessory—often requiring minimal post-processing to meet dimensional and surface requirements.

This process excels at producing accessories with complex geometries (e.g., intricate brackets, thin-walled housings) that would be costly or impossible to make with other methods.

1.2 Key Advantages for Accessory Production

Die casting for accessories outperforms traditional manufacturing (e.g., sand casting, CNC machining) in three critical areas, as shown in the 对比式 table below:

| Advantage | Die Casting for Accessories | Traditional Methods (e.g., Sand Casting) | Impact on Accessory Production |

| Efficiency | High-volume production (3,000–7,000 cycles/day for small accessories) | Slow (100–200 parts/day for similar sizes) | Cuts lead times by 70–80% for bulk accessory orders |

| Precision | Dimensional accuracy of ±0.1 mm; surface finish of Ra 1.6–6.3 μm | Accuracy of ±0.5–1 mm; rough surface (Ra 12.5–25 μm) | Eliminates 80–90% of post-machining for precision accessories (e.g., electronic brackets) |

| Cost-Effectiveness | Material utilization rate of 90–95% (minimal waste) | Material utilization of 60–70% (high scrap) | Lowers per-unit costs by 30–50% for high-volume accessory runs |

2. Material Selection: Matching Alloys to Accessory Needs

The right material determines an accessory’s performance, durability, and cost. Below is a detailed breakdown of the most common alloys for accessory die casting, organized by use case:

| Alloy Type | Key Properties | Ideal Accessories | Application Examples |

| Aluminum Alloys (ADC12, A380) | – Lightweight (2.7 g/cm³)- Excellent thermal conductivity- Good corrosion resistance (with surface treatment)- Low cost (vs. magnesium/copper alloys) | Heat-sensitive, lightweight accessories; high-volume consumer goods | Electronic device heat sinks, new energy vehicle (NEV) motor housings, automotive chassis components |

| Zinc Alloys | – Low melting point (380–420°C, reduces mold wear)- High dimensional stability (minimal shrinkage)- Easy to plate/paint (ideal for cosmetic parts) | Cosmetic accessories; small, precision components | Smartphone frames, remote control bodies, household hardware (e.g., door handles) |

| Magnesium Alloys | – Ultra-lightweight (1.8 g/cm³, lightest structural metal)- High strength-to-weight ratio- Good electromagnetic shielding | Weight-critical, high-performance accessories | Aerospace brackets, high-end laptop casings, portable device frames |

| Copper Alloys | – Exceptional electrical/thermal conductivity- High hardness (HRC 30–40 after heat treatment)- Strong wear resistance | Conductive, durable accessories | Electrical connectors, motor rotors, industrial valve components |

Example: Material Choice for NEV Accessories

For an NEV reducer housing (a critical accessory), ADC12 aluminum alloy is preferred:

- Its lightweight nature reduces vehicle weight (boosting fuel efficiency).

- Good thermal conductivity dissipates heat from the reducer.

- Low cost aligns with high-volume NEV production needs.

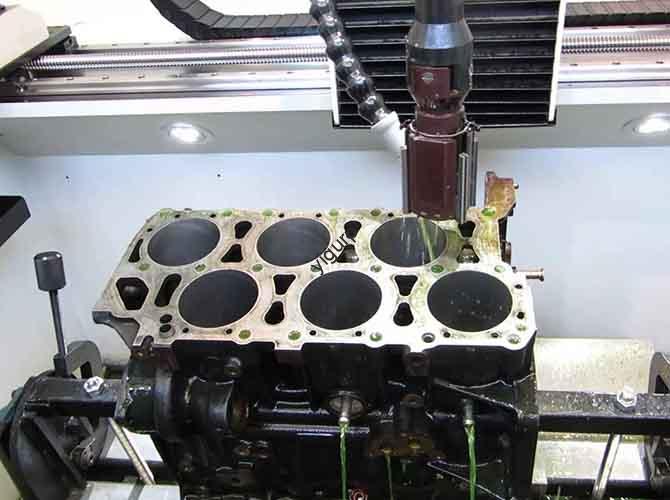

3. Critical Processes: From Mold to Finished Accessory

The quality of die-cast accessories depends on mastering four key process stages. Below is a 线性叙述 of each step, with actionable tips for optimization:

3.1 Mold Design & Manufacturing

The mold is the foundation of quality accessories. Follow these best practices:

- Material: Use H13 hot-work mold steel—it withstands repeated thermal cycles (300–600°C) and extends mold life to 80,000–150,000 cycles.

- Heat Treatment: Apply vacuum quenching to H13 steel—this enhances hardness (HRC 48–52) and reduces mold distortion.

- Cooling System: Integrate an independent cooling circuit (e.g., 8 mm diameter channels) to control mold temperature difference (≤5°C). This prevents accessory defects like warping or porosity.

3.2 Die Casting Parameter Control

Precise parameter adjustment avoids common accessory defects (e.g., porosity, cold shuts). Use these guidelines:

- Injection Speed: Adopt segmented injection mode—slow for filling (to avoid turbulence) and fast for shrinkage (to compact the metal). For thin-walled accessories (≤1 mm), use “slow injection filling (0.5–1 m/s) + fast injection shrinkage (3–5 m/s)”.

- Pressure: Maintain 30–80 MPa for aluminum alloy accessories; 20–50 MPa for zinc alloy parts. Too low pressure causes porosity; too high leads to mold damage.

- Temperature: Heat aluminum alloys to 650–700°C, zinc alloys to 380–420°C. Consistent molten metal temperature ensures uniform accessory density.

3.3 Post-Processing for Accessory Perfection

Most die-cast accessories need minimal post-processing, but key steps enhance performance and aesthetics:

- Shot Blasting: Use 80–120 grit steel shots to improve surface roughness (from Ra 6.3 μm to Ra 1.6 μm)—critical for accessories requiring painting or anodizing.

- CNC Finishing: Target high-precision areas (e.g., mounting holes) with CNC machining—achieving tolerances of ±0.05 mm for critical accessory features.

- Surface Treatment: Apply anodizing (for aluminum accessories) to boost corrosion resistance; use electroplating (for zinc accessories) to enhance cosmetic appeal (e.g., chrome-plated hardware).

3.4 Quality Testing: Ensure Accessory Consistency

No accessory leaves the factory without rigorous testing. Key checks include:

- Water Pressure Testing: For sealed accessories (e.g., pump bodies), test at 1–3 MPa to detect leaks—critical for hydraulic or fluid-handling applications.

- Dimensional Inspection: Use coordinate measuring machines (CMMs) to verify 10–15 key dimensions per batch—ensuring ±0.1 mm accuracy for all accessories.

- Porosity Checks: Use X-ray or ultrasonic testing for high-stress accessories (e.g., automotive chassis components)—reject parts with porosity >2% (to avoid failure under load).

4. Key Application Areas: Accessories Across Industries

Die casting for accessories serves diverse sectors, each with unique needs. Below is a 行业 – by – 行业 breakdown with specific examples:

4.1 Automotive Industry

The automotive sector is the largest user of die-cast accessories, relying on them for:

- Engine Components: Pipe fittings, sensor housings (aluminum alloy ADC12).

- Transmission Systems: Reducer housings, gear covers (aluminum alloy A380).

- NEV-Specific Parts: Motor housings, battery brackets (magnesium alloy for weight savings).

These accessories require high strength and dimensional stability—die casting delivers both at scale.

4.2 Electronic & Electrical Appliances

For consumer electronics, die-cast accessories prioritize lightweight and thermal performance:

- Device Housings: Smartphone frames, laptop hinges (zinc alloy for precision; aluminum for heat dissipation).

- Internal Components: Heat sinks (aluminum alloy, leveraging high thermal conductivity), circuit board brackets (zinc alloy for electromagnetic shielding).

4.3 Mechanical Equipment

Mechanical accessories demand durability and airtightness—die casting meets these via:

- Hydraulic/Pneumatic Parts: Pump bodies, valve blocks (aluminum alloy with vacuum die casting to reduce porosity).

- Structural Components: Conveyor brackets, machine covers (steel-reinforced aluminum alloy for high strength).

4.4 Other Fields

- Architectural Decoration: Aluminum alloy curtain wall brackets, decorative hardware (anodized for weather resistance).

- Home Hardware: Zinc alloy door handles, cabinet hinges (electroplated for aesthetics and rust resistance).

5. Future Trends: Innovations in Die Casting for Accessories

As manufacturing evolves, die casting for accessories is set to become even more versatile. Key trends include:

- Smart Mold Monitoring: Integrating sensors into molds to track temperature, pressure, and wear in real time—reducing defect rates by 40–50%.

- Eco-Friendly Materials: Using recycled aluminum/zinc alloys (now accounting for 30–40% of raw materials) to lower carbon footprints.

- 3D-Printed Molds: For small-batch custom accessories (e.g., prototype automotive parts), 3D-printed molds cut lead times from weeks to days.

Yigu Technology’s Perspective

At Yigu Technology, we see die casting for accessories as a solution that balances quality, efficiency, and cost. For automotive clients, we use H13 steel molds with vacuum quenching and independent cooling circuits—ensuring reducer housings meet ±0.05 mm tolerance and 200,000+ cycle mold life. For electronics clients, we optimize zinc alloy parameters (380°C molten temp, 40 MPa pressure) to deliver smartphone frames with Ra 1.6 μm surface finish. We also adopt vacuum die casting for hydraulic accessories, cutting porosity to <1% and passing 3 MPa water pressure tests. Ultimately, die casting for accessories isn’t just a process—it’s a way to turn complex designs into reliable, cost-effective products that drive industry innovation.

FAQ

- Can die casting for accessories produce parts with thin walls?

Yes—die casting excels at thin-walled accessories. For aluminum alloys, wall thicknesses as low as 0.5 mm are achievable; for zinc alloys, 0.3 mm. The key is using high injection speeds (3–5 m/s) and a well-designed cooling system to prevent premature solidification.

- What’s the minimum order quantity (MOQ) for die-cast accessories?

MOQs vary by mold cost: For low-cost zinc alloy molds (\(5,000–\)15,000), MOQs start at 1,000–5,000 parts. For high-precision aluminum alloy molds (\(20,000–\)50,000), MOQs are typically 10,000+ parts to justify mold investment. For custom prototypes, 3D-printed molds enable MOQs of 10–100 parts.

- How long does it take to produce die-cast accessories?

Lead times depend on mold production and cycle time:

- Mold manufacturing: 2–4 weeks for standard accessories; 4–8 weeks for complex designs.

- Production: For small accessories (e.g., smartphone hinges), 10,000 parts take 1–2 days (3,000 cycles/day). For larger parts (e.g., NEV motor housings), 10,000 parts take 5–7 days.