Liquid die casting (also known as squeeze casting or liquid die forging) is a game-changing metal-forming technology that bridges the gap between traditional die casting and forging. Unlike conventional die casting—where molten metal solidifies rapidly with high risk of porosity—liquid die casting applies continuous mechanical pressure during solidification, creating dense, high-strength components. For manufacturers needing parts that balance complex shapes with dynamic load resistance (e.g., automotive structural parts, aerospace components), liquid die casting is a transformative solution. This article systematically breaks down its working principles, core advantages, process variants, and real-world applications to help you unlock its full potential.

1. Core Definition & Working Principles of Liquid Die Casting

To understand liquid die casting’s uniqueness, it’s essential to clarify its fundamental mechanism—how it combines casting’s shape flexibility with forging’s strength. This section uses a linear 叙述 structure with key terms highlighted for clarity.

1.1 Fundamental Definition

Liquid die casting is a near-net forming process that injects molten metal (aluminum, magnesium, copper alloys) into a precision mold, then applies continuous static pressure (50-200 MPa) via a hydraulic punch until the metal fully solidifies. Its defining trait is the “pressure-assisted solidification”—this pressure squeezes out residual gas and shrinkage holes, resulting in a component with >99% density (vs. 95-97% for traditional die casting).

Unlike forging (which uses solid metal billets), liquid die casting starts with liquid metal—retaining the ability to form complex features (e.g., integrated cooling channels, fine threads) while achieving forging-level mechanical properties.

1.2 Step-by-Step Working Process

The liquid die casting cycle follows 5 critical stages, each optimized to maximize density and precision:

- Mold Preparation: Preheat the mold to 180-250°C (for aluminum) and apply a thin release agent (0.05-0.1mm thickness) to prevent sticking. This ensures uniform heat distribution during filling.

- Metal Injection: Pour molten metal (680-720°C for aluminum alloy A356) into the mold cavity at a controlled speed (0.5-2 m/s)—slower than traditional die casting to avoid turbulence and gas entrainment.

- Pressure Application: Activate the hydraulic punch to apply 80-150 MPa pressure within 2-3 seconds of injection. Maintain this pressure throughout solidification (10-30 seconds, depending on part thickness).

- Solidification Under Pressure: The continuous pressure eliminates voids by:

- Compressing gas bubbles to <0.01mm (too small to affect strength).

- Refilling shrinkage gaps with molten metal from the sprue.

This step is why liquid die casting parts have 30-50% higher fatigue strength than traditional die castings.

- Demolding & Finishing: Open the mold, eject the part, and trim excess material (runners, flash). Post-processing (e.g., T6 heat treatment for aluminum) further enhances mechanical properties—tensile strength can reach 350-400 MPa.

2. Key Variants of Liquid Die Casting: Direct vs. Indirect Extrusion

Liquid die casting has two main process variants, each suited to different part complexities and production needs. The table below compares their technical differences, advantages, and ideal applications:

| Process Variant | Working Mechanism | Pressure Range | Key Advantages | Ideal Applications |

| Direct Extrusion Liquid Die Casting | The punch applies pressure directly to the molten metal surface (no intermediate channels). The mold cavity is filled via gravity before pressure is activated. | 100-200 MPa | – Highest density (>99.5%) and mechanical properties.- No sprue-related material waste (3-5% less scrap than indirect).- Uniform pressure distribution for thick-walled parts. | High-criticality components: aerospace engine brackets, military equipment transmission parts, hydraulic cylinder blocks (require strict pressure tightness). |

| Indirect Extrusion Liquid Die Casting | Pressure is transmitted to the molten metal via a sprue or runner system (the punch pushes a metal plunger, which forces liquid into the cavity). | 50-120 MPa | – Lower mold complexity (cheaper tooling by 20-30%).- Faster cycle time (15-20 seconds/part vs. 25-30 seconds for direct).- Suitable for parts with thin-walled sections (<3mm). | General industrial parts: automotive wheels, motorcycle frame components, home appliance pump bodies (balance cost and performance). |

2.1 Critical Selection Factors for Variants

Choose between direct and indirect extrusion based on three criteria:

- Part Criticality: If the part bears dynamic loads (e.g., automotive suspension brackets), direct extrusion is better—its higher density ensures fatigue resistance.

- Cost Tolerance: For high-volume, low-cost parts (e.g., 100,000+ automotive wheels/year), indirect extrusion’s cheaper tooling and faster cycles reduce per-part costs by 15-20%.

- Wall Thickness: Direct extrusion excels at thick-walled parts (>5mm), while indirect extrusion is more efficient for thin-walled features (2-3mm) due to better flow control.

3. Core Advantages: Why Liquid Die Casting Outperforms Traditional Processes

Liquid die casting’s value lies in its ability to solve the “strength vs. complexity” trade-off that plagues traditional casting and forging. The table below compares it to traditional die casting and gravity casting across 6 key metrics:

| Performance Metric | Liquid Die Casting | Traditional Die Casting | Gravity Casting |

| Material Density | >99% (near-full density) | 95-97% (porosity 3-5%) | 92-95% (high porosity) |

| Mechanical Properties | Tensile strength: 350-400 MPa; Fatigue strength: 150-180 MPa | Tensile strength: 280-320 MPa; Fatigue strength: 100-120 MPa | Tensile strength: 250-280 MPa; Fatigue strength: 80-100 MPa |

| Complexity Capability | Handles integrated features (cooling channels, threads) with <3mm wall thickness | Handles complex shapes but with higher porosity in thin sections | Limited to simple shapes (no fine features) |

| Production Efficiency | Cycle time: 15-30 seconds/part | Cycle time: 10-20 seconds/part (faster but lower quality) | Cycle time: 5-10 minutes/part (slowest) |

| Material Utilization | 90-95% (low scrap) | 85-90% (moderate scrap) | 75-80% (high scrap) |

| Post-Processing Need | Minimal (only trimming + optional heat treatment) | Extensive (impregnation to seal porosity + machining) | Extensive (machining to correct dimensional errors) |

3.1 Real-World Advantage Example: Automotive Wheel Production

A leading automotive manufacturer switched from gravity casting to indirect extrusion liquid die casting for aluminum alloy wheels:

- Before: Gravity cast wheels had 8% porosity, required 2 hours of machining per wheel, and failed fatigue tests at 100,000 cycles.

- After: Liquid die cast wheels had <1% porosity, required 30 minutes of machining, and passed fatigue tests at 180,000 cycles.

- Cost Impact: Per-wheel production cost dropped by $12 (due to less scrap and machining), and warranty claims related to wheel failure fell by 75%.

4. Key Application Scenarios: Where Liquid Die Casting Shines

Liquid die casting excels in industries that demand both complex geometries and high mechanical performance. Below are its three most impactful application fields, with specific examples:

4.1 Automotive Industry: Lightweight & Safety-Critical Parts

The automotive sector is the largest user of liquid die casting, driven by the need for lightweighting (to improve fuel efficiency) and crash safety:

- Structural Components: Front subframes, suspension brackets, and brake calipers use liquid die cast aluminum alloys (A356, AlSi10Mg). These parts must withstand 100,000+ km of road vibration—liquid die casting’s high fatigue strength prevents cracking. For example, Tesla’s Model Y front subframe uses liquid die casting to integrate 12 components into one, reducing weight by 18kg vs. a welded steel subframe.

- EV-Specific Parts: Battery pack frames and motor housings rely on liquid die casting’s pressure tightness. A 5mm-thick liquid die cast battery frame can withstand 1.2MPa internal pressure (vs. 0.8MPa for traditional die casting), ensuring no coolant leakage in EVs.

- Transmission Parts: Gearbox housings and clutch carriers use liquid die cast magnesium alloys (AZ91D). Their high strength-to-weight ratio (1:1.8) reduces transmission weight by 25%, improving vehicle acceleration and handling.

4.2 Aerospace & Defense: High-Reliability Components

Liquid die casting meets the strict standards of aerospace and defense, where failure is not an option:

- Aerospace Brackets: Titanium alloy (Ti-6Al-4V) brackets for aircraft wings use direct extrusion liquid die casting. The process achieves 99.8% density, meeting the Aerospace Material Specification (AMS) 4999 for structural titanium parts. These brackets withstand -50°C to 150°C temperature extremes without deformation.

- Military Equipment: Armored vehicle transmission casings use liquid die cast copper-chromium-zinc alloys. Their tensile strength (450MPa) and impact resistance (150J/cm²) protect against battlefield vibrations and shrapnel.

4.3 Industrial Machinery: Heavy-Duty & Pressure-Bearing Parts

Industrial machinery relies on liquid die casting for parts that handle high pressure and continuous operation:

- Hydraulic Components: Pump bodies, valve cores, and cylinder liners use liquid die cast aluminum alloys. A liquid die cast hydraulic pump body can operate at 30MPa pressure for 10,000+ hours without leakage—vs. 5,000 hours for traditional die cast versions.

- Power Generation: Wind turbine hub components use liquid die cast magnesium alloys. Their lightweight design (30% lighter than steel) reduces turbine rotational inertia, increasing energy efficiency by 5-8%.

5. Process Optimization: Key Parameters to Maximize Quality

To achieve consistent results with liquid die casting, three parameters must be precisely controlled. The table below outlines their optimal ranges and impact on quality:

| Critical Parameter | Optimal Range (Aluminum Alloy A356) | Impact of Deviation |

| Injection Temperature | 680-720°C | – Too low (<680°C): Poor fluidity leads to underfilling.- Too high (>720°C): Increases oxide formation, reducing strength by 10-15%. |

| Applied Pressure | 80-120 MPa (indirect extrusion); 120-150 MPa (direct extrusion) | – Too low (<80 MPa): Porosity increases to 3-5% (fails pressure tightness tests).- Too high (>150 MPa): Causes mold wear (reduces die life by 20-30%). |

| Pressure Holding Time | 10-20 seconds (thin parts <5mm); 20-30 seconds (thick parts >5mm) | – Too short (<10 seconds): Shrinkage holes form in thick sections.- Too long (>30 seconds): Increases cycle time (reduces production efficiency by 15%). |

5.1 Advanced Optimization: Simulation-Driven Parameter Setting

Modern liquid die casting uses CAE simulation software (e.g., MAGMA, AnyCasting) to predict solidification behavior:

- The software maps temperature distribution and pressure transmission to identify potential hot spots (which cause shrinkage) and low-pressure zones (which cause porosity).

- For example, simulating a 10mm-thick aluminum bracket revealed that increasing pressure holding time from 15s to 22s eliminated shrinkage in the bracket’s center—reducing defect rate from 8% to 0.5%.

6. Yigu Technology’s Perspective on Liquid Die Casting

At Yigu Technology, we see liquid die casting as the “future of high-performance metal forming”—especially for EVs and aerospace. Many manufacturers hesitate to adopt it due to higher initial tooling costs, but the reality is that its 30-50% longer part life and 20% lower scrap rate deliver ROI within 1-2 years for high-volume projects.

We recommend a phased adoption strategy: Start with indirect extrusion for non-critical parts (e.g., automotive wheels) to master parameter control, then scale to direct extrusion for safety-critical components (e.g., EV battery frames). For clients, we provide customized DFM (Design for Manufacturability) services—redesigning traditional multi-part assemblies into single liquid die cast components (e.g., integrating 5 welded parts into one, cutting costs by 30%).

We also advocate green manufacturing integration: Liquid die casting’s high material utilization (90-95%) and minimal post-processing align with sustainability goals. By combining it with recycled aluminum (up to 50% recycled content), manufacturers can reduce carbon emissions by 25-30% vs. traditional processes.

7. FAQ: Common Questions About Liquid Die Casting

Q1: Can liquid die casting be used for high-melting-point metals like steel or titanium?

Steel is not feasible—its melting point (1500°C+) exceeds the heat resistance of standard liquid die casting molds (H13 steel deforms at 600-700°C). Titanium is possible but requires specialized molds (e.g., ceramic-coated H13 steel) and higher pressure (150-200 MPa). Currently, titanium liquid die casting is limited to aerospace (low-volume, high-value parts) due to high costs.

Q2: What is the maximum part size/weight that liquid die casting can produce?

Most commercial liquid die casting machines handle parts weighing 0.5-50kg and measuring up to 1.5m in length. For larger parts (e.g., 100kg wind turbine hubs), specialized 2000-ton+ machines are available, but they are costly ($1-2M) and only economical for high-volume production (>10,000 units/year).

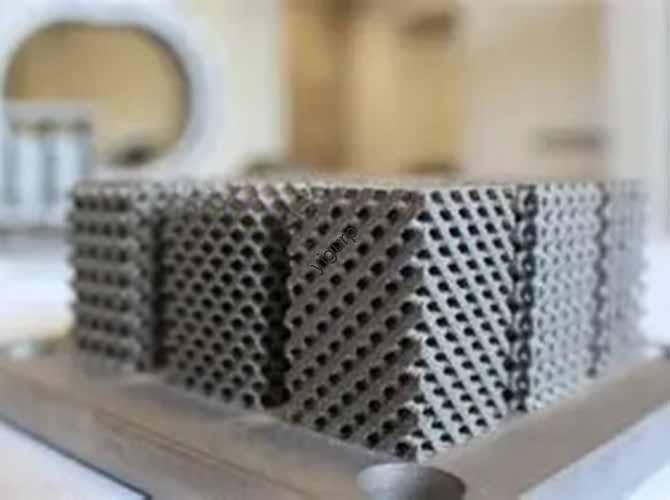

Q3: How does liquid die casting compare to 3D printing for small-batch complex parts?

For small batches (<1000 units), 3D printing (e.g., SLM for metal) is more flexible—no mold is needed. However, liquid die casting has three advantages for larger batches: 1. Faster production (15-30s/part vs. 1-2 hours/part for 3D printing). 2. Lower per-part cost (\(5-10 vs. \)50-100 for 3D printing). 3. Higher density (>99% vs. 95-98% for 3D printing). Choose 3D printing for prototypes, liquid die casting for production.