If you’re wondering whether aluminium machining parts are right for your project, how to choose the best materials, or what processes deliver the highest quality results—you’ve come to the right place. The short answer is: aluminium machining parts are versatile, cost-effective, and ideal for countless industries, from aerospace to consumer electronics, thanks to aluminium’s lightweight, corrosion-resistant, and highly machinable properties. But to make the most of them, you need to understand the details—like material grades, machining techniques, design tips, and quality control. Let’s break this down step by step.

Why Choose Aluminium for Machining Parts?

Aluminium stands out as a top choice for machining parts, and it’s not just because of its low cost. Its unique combination of physical and mechanical properties makes it a go-to material for engineers and manufacturers worldwide. Let’s start with the basics: aluminium is about one-third the weight of steel, which is a game-changer for applications where weight reduction matters—think aircraft components or electric vehicle parts. Even better, it doesn’t sacrifice strength when machined properly; many aluminium alloys can match the strength of low-carbon steel while keeping weight down.

Corrosion resistance is another big advantage. Unlike steel, which rusts easily, aluminium forms a natural oxide layer when exposed to air. This layer acts as a protective barrier, preventing further damage. For parts used in outdoor or wet environments—like marine hardware or outdoor electronics—this means less maintenance and a longer lifespan. I once worked with a client who switched from steel to aluminium for their boat’s railing components; not only did they cut the weight by 40%, but they also eliminated the need for annual repainting to prevent rust.

Machinability is where aluminium really shines. It’s soft enough to be cut, drilled, and shaped quickly, which reduces production time and costs. Most aluminium alloys have a machinability rating above 70 (with 100 being the easiest to machine), compared to steel’s rating of around 40. This means faster cycle times on the machine, less wear on tools, and lower energy use. A study by the Aluminum Association found that machining aluminium uses 50% less energy than machining steel for the same part, which adds up to significant savings for large production runs.

Finally, aluminium is highly recyclable. Over 75% of all aluminium ever produced is still in use today, according to the International Aluminium Institute. For companies focused on sustainability—whether to meet regulatory requirements or consumer demand—aluminium machining parts offer a way to reduce their carbon footprint. I recently consulted with a consumer electronics brand that switched to recycled aluminium for their laptop casings; they not only reduced their material costs by 15% but also cut their carbon emissions related to material sourcing by 60%.

Key Aluminium Alloys for Machining Parts

Not all aluminium alloys are created equal—each has unique properties that make it better suited for specific applications. Choosing the right alloy is critical to ensuring your part performs well, lasts long, and stays within budget. Let’s look at the most common alloys used in machining and their best uses.

6061 Aluminium Alloy

6061 is often called the “workhorse” of aluminium alloys, and for good reason. It’s one of the most widely used alloys for machining parts because it balances strength, machinability, and cost. It has a tensile strength of 37,000 psi (pounds per square inch) and a yield strength of 30,000 psi, which is strong enough for most general-purpose parts. It’s also easy to machine—thanks to its medium hardness—and can be heat-treated to increase its strength even further.

Common applications for 6061 include:

- Structural components (like brackets and frames)

- Automotive parts (such as valve covers and intake manifolds)

- Consumer electronics (laptop bodies and smartphone frames)

- Plumbing fixtures (faucet handles and pipe fittings)

A case in point: a client in the automotive industry used 6061 to machine engine mounts for their compact cars. The alloy’s strength kept the mounts stable under vibration, while its machinability allowed them to produce 500 parts per day—20% more than they could with a harder alloy like 7075.

7075 Aluminium Alloy

If you need maximum strength, 7075 is the alloy to choose. It’s one of the strongest aluminium alloys available, with a tensile strength of 83,000 psi and a yield strength of 73,000 psi—nearly twice that of 6061. This makes it ideal for high-stress applications where strength is non-negotiable. However, its high strength comes with a trade-off: it’s harder to machine than 6061, so it requires sharper tools and slower cutting speeds, which can increase production costs.

Common applications for 7075 include:

- Aerospace components (wing spars and landing gear parts)

- High-performance automotive parts (roll cages and suspension components)

- Sporting goods (bicycle frames and climbing equipment)

I worked with an aerospace supplier that used 7075 to machine aircraft wing ribs. The alloy’s strength was critical to withstanding the forces of flight, but they had to adjust their machining process—using carbide tools instead of high-speed steel and reducing cutting speeds by 30%—to get clean, accurate cuts. The extra effort was worth it, though: the parts met strict FAA standards and had a 99.5% pass rate in quality control.

5052 Aluminium Alloy

For parts that need flexibility and corrosion resistance, 5052 is a great option. It’s a non-heat-treatable alloy, which means it can’t be strengthened with heat, but it has excellent formability and resistance to saltwater corrosion. Its tensile strength is lower than 6061 (about 30,000 psi), but it’s much more ductile, making it easy to bend and shape without cracking.

Common applications for 5052 include:

- Marine parts (boat hulls and fuel tanks)

- Chemical processing equipment (tanks and pipes)

- Sheet metal parts (signs and enclosures)

A client in the marine industry used 5052 to machine fuel tanks for small boats. The alloy’s resistance to saltwater corrosion meant the tanks didn’t leak or degrade over time, and its formability allowed them to create custom shapes to fit tight spaces in the boat’s hull. They reported zero failures in the tanks over a 5-year period, which is a huge win for marine applications.

Comparison of Common Aluminium Alloys for Machining

To make it easier to choose the right alloy, here’s a quick comparison table:

| Alloy | Tensile Strength (psi) | Yield Strength (psi) | Machinability | Corrosion Resistance | Best For |

| 6061 | 37,000 | 30,000 | Excellent | Good | General-purpose parts, structural components |

| 7075 | 83,000 | 73,000 | Fair | Moderate | High-stress parts, aerospace, high-performance automotive |

| 5052 | 30,000 | 17,000 | Good | Excellent | Marine parts, chemical equipment, sheet metal |

Essential Machining Processes for Aluminium Parts

Once you’ve chosen the right alloy, the next step is to select the machining process that best fits your part’s design, tolerance requirements, and production volume. Let’s break down the most common processes and when to use each one.

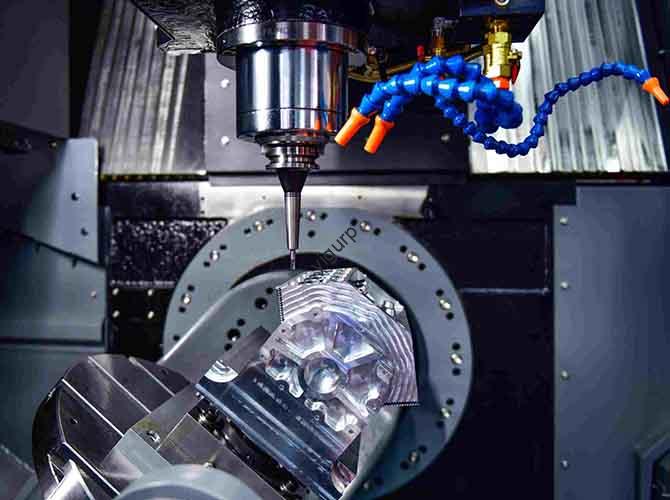

CNC Milling

CNC (Computer Numerical Control) milling is one of the most versatile machining processes for aluminium parts. It uses rotating cutting tools to remove material from a workpiece, and it can create complex shapes—like slots, holes, and 3D features—with high accuracy. CNC mills can handle both small and large parts, and they’re ideal for low to high production volumes.

One of the biggest advantages of CNC milling for aluminium is its precision. Most CNC mills have a tolerance of ±0.001 inches, which is critical for parts that need to fit together perfectly—like gearboxes or electronic enclosures. I worked with a medical device manufacturer that used CNC milling to machine aluminium housings for their diagnostic equipment. The housings needed to have precise holes for cables and connectors, and CNC milling allowed them to hit those tolerances every time, with a defect rate of less than 0.5%.

CNC milling is also great for prototyping. Since it’s computer-controlled, you can easily adjust the design in software and produce a new prototype in a matter of hours. This is a huge time-saver compared to traditional machining methods, which require manual adjustments to tools and setups.

CNC Turning

CNC turning is used to create cylindrical parts—like shafts, bolts, and bushings—by rotating the workpiece while a cutting tool moves along its length. It’s faster than CNC milling for cylindrical parts, and it’s ideal for high production volumes.

Aluminium’s softness makes it perfect for CNC turning. The cutting tool glides through the material smoothly, creating a clean, smooth surface finish. Most turned aluminium parts have a surface finish of 32 to 63 microinches, which is smooth enough for most applications without additional polishing.

A client in the fastener industry used CNC turning to produce aluminium bolts for solar panels. They needed to produce 10,000 bolts per day, and CNC turning allowed them to meet that volume while maintaining a tolerance of ±0.002 inches. The bolts also had a smooth surface finish that prevented corrosion and ensured a tight fit in the solar panel frames.

Drilling and Tapping

Drilling and tapping are essential processes for creating holes in aluminium parts—holes that are often used to fasten parts together with screws or bolts. Drilling creates a hole, while tapping adds threads to the hole so that a screw can be inserted.

Aluminium is easy to drill and tap, but there are a few tips to keep in mind. First, use sharp drill bits and taps—dull tools can cause the aluminium to tear, creating a rough hole that’s hard to thread. Second, use cutting fluid to keep the tool cool and reduce friction. Cutting fluid also helps to flush away chips, which can clog the hole and damage the tool.

I once consulted with a furniture manufacturer that was having trouble with tapping aluminium legs for their chairs. Their taps were breaking frequently, and the threads were coming out rough. After switching to sharp carbide taps and using a water-based cutting fluid, they reduced tap breakage by 80% and improved the quality of the threads, which made it easier to assemble the chairs.

Surface Finishing

Surface finishing is the final step in machining aluminium parts, and it serves two main purposes: to improve the part’s appearance and to enhance its performance (like increasing corrosion resistance or reducing friction). The most common surface finishes for aluminium parts include:

- Anodizing: Anodizing creates a thick, hard oxide layer on the surface of the aluminium. It’s available in a variety of colors, and it increases corrosion resistance and wear resistance. Anodized aluminium parts are often used in consumer electronics (like smartphone cases) and architectural applications (like window frames).

- Powder Coating: Powder coating involves applying a dry powder to the aluminium surface and then heating it to melt and cure the powder. It’s durable, available in many colors, and it’s ideal for parts that need a tough, scratch-resistant finish—like outdoor furniture or automotive parts.

- Polishing: Polishing creates a shiny, mirror-like finish on aluminium parts. It’s often used for decorative parts—like trophy bases or decorative trim—but it doesn’t add much to corrosion resistance, so it’s best for indoor applications.

A client in the architectural industry used anodizing to finish aluminium window frames for a high-rise building. The anodized finish not only gave the frames a sleek, modern look but also protected them from the elements—after 10 years, the frames still looked new, with no signs of corrosion or fading.

Design Tips for High-Quality Aluminium Machining Parts

Even the best machining processes can’t fix a poor design. To ensure your aluminium parts are strong, durable, and easy to machine, follow these design tips.

Keep Tolerances Realistic

Tight tolerances (like ±0.0005 inches) might seem like a good idea for precision parts, but they can increase production costs and lead to more defects. Aluminium is a soft material, and it can expand or contract slightly during machining—especially if the part is large or the machining process generates a lot of heat. This means that extremely tight tolerances are often hard to maintain.

Instead, set tolerances based on what the part actually needs. For example, a bracket that holds a battery might only need a tolerance of ±0.01 inches, while a gear that meshes with other gears might need a tolerance of ±0.001 inches. I worked with a robotics company that was specifying a tolerance of ±0.0005 inches for a non-critical aluminium bracket. After adjusting the tolerance to ±0.002 inches, they reduced their production costs by 15% and eliminated 90% of their defective parts.

Avoid Sharp Corners

Sharp corners are a big no-no in aluminium machining. They can cause stress concentrations in the part, which can lead to cracking or breaking under load. They also make machining harder— the cutting tool can get stuck in the corner, creating a rough surface finish or even damaging the tool.

Instead, use fillets (rounded corners) or chamfers (angled corners) on all edges. Fillets are better for reducing stress concentrations, while chamfers are better for parts that need to fit into tight spaces. A good rule of thumb is to use a fillet radius of at least 0.03 inches for small parts and 0.125 inches for large parts.

A client in the automotive industry had a problem with aluminium suspension arms cracking at the corners. After adding fillets with a 0.125-inch radius to the corners, they eliminated the cracking issue entirely. The fillets also made the parts easier to machine, reducing production time by 10%.

Design for Machinability

Designing for machinability means creating parts that are easy to machine with minimal setup time and tool changes. Here are a few ways to do that:

- Minimize complex features: Complex features—like deep slots or undercuts—require special tools and setups, which increase production time and costs. If possible, simplify the design.

- Use standard sizes: Use standard hole sizes (like 0.25 inches or 0.5 inches) and thread sizes (like 1/4-20 or 3/8-16) instead of custom sizes. Standard tools are cheaper and easier to find, which reduces costs.

- Avoid deep cavities: Deep cavities are hard to machine because the cutting tool has to reach into the cavity, which can cause vibration and poor surface finish. If you need a deep cavity, consider making it shallower or using a different design.

I consulted with a consumer goods company that was designing an aluminium coffee maker base with a deep, complex cavity. The cavity required a special tool and multiple setups, which made production slow and expensive. After redesigning the base to eliminate the deep cavity, they reduced production time by 25% and cut costs by 20%.

Quality Control for Aluminium Machining Parts

Quality control is critical to ensuring your aluminium parts meet your specifications and perform well in their application. Let’s look at the key steps in quality control.

Dimensional Inspection

Dimensional inspection involves checking the part’s size, shape, and position to ensure it meets the tolerance requirements. The most common tools for dimensional inspection include:

- Calipers: Used to measure the length, width, and thickness of parts. They have a tolerance of ±0.001 inches, which is good for most small parts.

- Micrometers: Used to measure small dimensions—like the diameter of a shaft—with high accuracy. They have a tolerance of ±0.0001 inches, which is ideal for precision parts.

- Coordinate Measuring Machines (CMMs): Used to measure complex parts with multiple features. CMMs use a probe to map the part’s surface and compare it to the design in software. They have a tolerance of ±0.0005 inches, which is perfect for high-precision parts.

A client in the aerospace industry used CMMs to inspect every aluminium wing component they produced. The CMMs checked the part’s dimensions, including the position of holes and the shape of curves, and compared them to the design. Any part that was outside the tolerance of ±0.001 inches was rejected, which ensured that the wings met strict FAA standards.

Surface Finish Inspection

Surface finish inspection checks the smoothness of the part’s surface. A rough surface finish can cause problems—like increased friction or poor corrosion resistance—so it’s important to ensure the finish meets your requirements.

The most common tool for surface finish inspection is a profilometer, which measures the surface roughness in microinches. Most aluminium parts have a surface finish of 32 to 63 microinches, but some applications—like medical devices or optical components—require a smoother finish (16 microinches or less).

I worked with a medical device manufacturer that used a profilometer to inspect the surface finish of aluminium surgical tools. The tools needed a smooth finish to prevent bacteria from sticking to them, so they set a maximum surface roughness of 16 microinches. The profilometer helped them ensure that every tool met that standard, with a pass rate of 99.8%.

Material Verification

Material verification ensures that the aluminium alloy you’re using is the one you specified. Using the wrong alloy can lead to serious problems—like parts that break under load or corrode quickly.

The most common method for material verification is spectroscopy, which uses light to analyze the chemical composition of the aluminium. Spectroscopy can identify the alloy type (like 6061 or 7075) and check for impurities—like copper or iron—that can affect the part’s performance.

A client in the automotive industry had a problem with aluminium engine parts failing during testing. After using spectroscopy to analyze the failed parts, they discovered that their supplier had mistakenly used 6061 alloy instead of the specified 7075. The 6061 alloy didn’t have enough strength to withstand the engine’s heat and vibration, leading to premature failure. By implementing regular spectroscopy checks, they were able to catch the mistake before more defective parts were produced, saving them over $100,000 in rework and lost production time.

Yigu Technology’s Perspective on Aluminium Machining Parts

At Yigu Technology, we’ve worked with hundreds of clients across industries—from aerospace to consumer electronics—to develop and produce high-quality aluminium machining parts. Based on our years of experience, the key to success with aluminium parts lies in alignment between material selection, design, and machining process.

We often see clients rush to choose a high-strength alloy like 7075 without considering their actual needs, only to face higher production costs and longer lead times. In most cases, 6061 is more than sufficient for general-purpose parts, offering the perfect balance of performance and cost. We also emphasize the importance of design for machinability; small adjustments—like adding fillets or using standard hole sizes—can cut production time by 20-30% while improving part durability.

Sustainability is another area we prioritize. As more clients aim to reduce their carbon footprint, we’ve expanded our use of recycled aluminium, which not only lowers material costs but also reduces environmental impact. Our team works closely with clients to optimize every step of the process—from material sourcing to surface finishing—to ensure their aluminium parts meet performance goals, stay within budget, and align with sustainability values.

FAQ About Aluminium Machining Parts

1. How do I choose between 6061, 7075, and 5052 aluminium alloys for my part?

Start by defining your part’s core needs:

- Choose 6061 if you need a versatile, cost-effective option for general-purpose parts (e.g., brackets, enclosures) that balances strength and machinability.

- Choose 7075 if your part will face high stress or load (e.g., aerospace components, high-performance automotive parts) and you’re willing to pay more for increased strength.

- Choose 5052 if corrosion resistance (especially to saltwater) or formability is critical (e.g., marine parts, sheet metal enclosures), even if strength is less of a priority.

2. What’s the difference between CNC milling and CNC turning for aluminium parts?

- CNC milling is ideal for non-cylindrical parts with complex features (e.g., slots, 3D shapes) and works for low to high production volumes. It’s great for prototyping and parts that need precise, multi-sided machining.

- CNC turning is designed for cylindrical parts (e.g., shafts, bolts) and is faster than milling for high-volume production. It produces smooth surface finishes and is more cost-effective for simple, round parts.

3. How can I reduce the cost of machining aluminium parts without sacrificing quality?

- Optimize tolerances: Use only as tight a tolerance as your part needs (e.g., ±0.002 inches instead of ±0.0005 inches) to avoid unnecessary machining time.

- Design for machinability: Minimize complex features (e.g., deep undercuts), use standard sizes for holes/threads, and add fillets to reduce tool wear.

- Choose the right alloy: Don’t overspecify—use 6061 instead of 7075 if strength needs allow, as it’s cheaper and easier to machine.

- Use recycled aluminium: It’s often 10-15% cheaper than virgin aluminium and has the same performance for most applications.

4. What surface finish is best for aluminium parts used outdoors?

Anodizing or powder coating are the top choices for outdoor aluminium parts:

- Anodizing creates a hard, corrosion-resistant oxide layer that stands up to rain, salt, and UV rays. It’s available in colors and doesn’t peel or chip easily.

- Powder coating offers a thick, durable finish that resists scratches and fading. It’s ideal for parts that need a bold color or extra protection (e.g., outdoor furniture, automotive trim).

Polishing is not recommended for outdoor use, as it doesn’t provide corrosion resistance and will dull or tarnish over time.