High-temperature silicone is a specialized elastomeric material engineered to withstand extreme thermal conditions while retaining critical properties like elasticity, chemical stability, and insulation. Unlike standard silicone (which typically maxes out at 150°C), it thrives in environments ranging from -60°C to 300°C (with some grades handling short bursts of 350°C+), making it indispensable for industrial sealing, mold manufacturing, and electronic protection. This article breaks down its core characteristics, classifications, application scenarios, and step-by-step usage guidelines—with clear comparisons and practical tips to help you select and apply it correctly.

1. Core Characteristics of High-Temperature Silicone

High-temperature silicone’s value stems from a unique combination of thermal and mechanical properties that outperform standard silicone and other elastomers. Below are its non-negotiable traits, backed by actionable data:

| Characteristic | Key Performance Metrics | Real-World Impact Example |

| Exceptional Thermal Resistance | – Continuous use range: -60°C to 300°C.- Short-term peak resistance: 350°C (special grades).- Maintains 80% of elasticity after 1,000 hours at 250°C. | An automotive engine gasket made from high-temperature silicone remains flexible and leak-free, even after 500+ hours of exposure to 220°C exhaust heat—unlike standard silicone, which hardens and cracks after 100 hours. |

| Weather & Environmental Durability | – Resists UV degradation (no brittleness after 2,000 hours of sunlight).- Withstands ozone, moisture, and salt spray (passes 500-hour salt fog tests). | A high-temperature silicone seal for outdoor industrial ovens shows no signs of cracking or discoloration after 1 year of exposure to rain, UV rays, and temperature fluctuations (-10°C to 280°C). |

| Chemical Stability | – Resists corrosion from weak acids (pH 4–10), alkalis, mineral oils, and most solvents (e.g., ethanol, acetone).- Compliant with FDA 21 CFR 177.2600 (food-grade variants). | A food-grade high-temperature silicone baking mold safely endures repeated exposure to 220°C oven heat and cleaning with harsh dish soap—no chemical leaching or material degradation. |

| Electrical Insulation | – Volume resistivity: ≥10¹⁴ Ω·cm (at 250°C).- Dielectric strength: ≥20 kV/mm (prevents electrical arcing). | High-temperature silicone potting compound protects LED driver modules in industrial lighting, maintaining insulation integrity even when the module reaches 180°C during operation. |

| Mechanical Flexibility | – Shore A hardness: 20–60 (adjustable for specific needs).- Elongation at break: ≥300% (handles thermal expansion/contraction). | A high-temperature silicone O-ring for a boiler pipe expands and contracts with temperature changes (100°C to 280°C) without leaking—its flexibility prevents stress cracks. |

2. Classification of High-Temperature Silicone

High-temperature silicone is categorized by two key factors: curing mechanism (how it hardens) and end-use (what it’s designed to do). Understanding these categories ensures you select the right grade for your project.

2.1 By Curing Mechanism

| Type | Curing Agent & Process | Key Advantages | Disadvantages | Ideal For |

| Additive (Platinum-Cure) High-Temperature Silicone | Cured with platinum catalysts; no byproducts released during curing. | – Environmentally friendly (odorless, no toxic emissions).- Low shrinkage (0.1–0.5%)—critical for precision molds.- Excellent transparency (for optical applications). | – Higher cost (20–30% more than condensation types).- Sensitive to contamination (e.g., sulfur ruins curing). | Precision molds (e.g., semiconductor component molds), food-grade applications (baking molds), and optical parts (light diffusers). |

| Condensation High-Temperature Silicone | Cured with tin catalysts; releases small byproducts (e.g., ethanol, acetic acid) during curing. | – Lower cost (budget-friendly for large-volume use).- Less sensitive to contamination.- Faster room-temperature curing (12–24 hours vs. 24–48 hours for additive). | – Mild odor (fades after curing).- Higher shrinkage (1–2%)—not for precision parts.- Byproducts may corrode sensitive metals (e.g., copper). | General industrial sealing (pipe gaskets), non-precision molds (rubber vulcanization molds), and low-cost repair projects (metal crack sealing). |

2.2 By End-Use

| Type | Form & Key Properties | Application Examples |

| High-Temperature Sealant | Paste or liquid form; cures to a flexible elastomer. | – Boiler pipe joints (prevents high-temperature gas leakage).- Ovens and furnaces (door seals, heating element gaskets).- Automotive exhaust systems (manifold gaskets). |

| High-Temperature Mold Adhesive | Flowable liquid; designed to capture fine details in molds. | – Die-casting molds (for metal alloys like aluminum).- Rubber vulcanization molds (for automotive hoses).- Food-grade baking molds (cake pans, chocolate molds). |

| High-Temperature Electronic Potting Compound | Viscous liquid; cures to a rigid or flexible solid (adjustable). | – Potting LED drivers, transformers, and power modules (protects from heat and moisture).- Encapsulating sensors in industrial machinery (withstands 250°C+). |

| High-Temperature Sheet Silicone | Pre-cured sheets (0.5–10mm thick); ready to cut and use. | – Gaskets for industrial ovens and fryers.- Insulation pads for electronic components (e.g., CPU heat sinks).- Seals for aerospace ducting (withstands 300°C). |

3. Key Application Scenarios

High-temperature silicone’s versatility makes it a staple across industries where heat, chemicals, or environmental stress are constant challenges.

| Industry | Specific Use Cases | Why High-Temperature Silicone Is Irreplaceable |

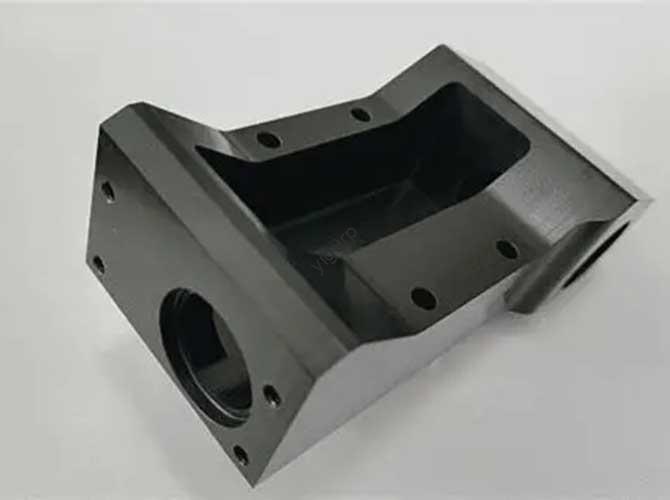

| Industrial Manufacturing | – Boiler/furnace seals and gaskets.- Die-casting molds for metal parts.- Potting for industrial sensors (e.g., temperature probes). | Withstands continuous exposure to 250°C–300°C; resists corrosion from industrial oils and cleaning solvents. |

| Automotive & Aerospace | – Engine gaskets (oil pans, exhaust manifolds).- Aerospace ducting seals (300°C+).- Battery pack insulation (electric vehicles). | Handles thermal cycling (from -40°C to 280°C) without degradation; lightweight (reduces vehicle/aerospace weight). |

| Food & Beverage | – Baking molds (cookies, bread).- Food processing equipment seals (e.g., conveyor belts).- Microwave-safe cookware liners. | FDA-compliant (no chemical leaching); withstands 220°C–250°C oven/microwave heat. |

| Electronics | – LED driver potting (high-power LEDs).- Transformer insulation.- Circuit board conformal coating (protects from heat/moisture). | Maintains electrical insulation at 180°C+; prevents short circuits from thermal expansion. |

| Home & DIY | – High-temperature repair (metal pipe cracks, ceramic tile fixes).- Grill/searing pan gaskets.- Homemade candle molds (heat-resistant to wax melting). | Easy to apply (room-temperature curing); no specialized tools needed for small projects. |

4. Step-by-Step Guide to Using High-Temperature Silicone

Proper application ensures high-temperature silicone performs as intended. Follow this workflow for sealing, mold making, or potting:

4.1 Preparation (Critical for Success)

- Surface Cleaning:

- Wipe the target surface (e.g., pipe joint, mold frame) with isopropyl alcohol (70–90%) to remove oil, dust, or rust. For metal surfaces, use a wire brush to remove corrosion—contaminants prevent adhesion.

- Tool & Material Prep:

- Gather tools: electronic scale (±0.1g), stir rod (glass/plastic), release agent (petroleum jelly for molds), and a vacuum degassing machine (for precision applications).

- Verify the silicone grade: Ensure it matches your temperature needs (e.g., 300°C for oven seals) and compliance requirements (e.g., FDA for food use).

4.2 Mixing (Avoid Curing Failures)

- Ratio Accuracy:

- Follow the manufacturer’s ratio (e.g., 10:1 for condensation silicone, 1:1 for additive silicone). Use an electronic scale—even a 1% error (e.g., 100:4 instead of 100:5) causes incomplete curing.

- Bubble Removal:

- Stir slowly in one direction (2–3 minutes) to avoid trapping air. For molds or potting, use a vacuum degassing machine (-0.1MPa) for 1–2 minutes—bubbles in the silicone cause leaks or voids.

4.3 Application (Tailor to End-Use)

| Use Case | Application Steps | Tips for Success |

| Sealing (Pipes/Ovens) | 1. Apply silicone in a continuous bead along the gap (3–5mm thick).2. Use a spatula to smooth the bead and ensure full contact.3. Let cure per instructions. | – Avoid over-applying (wastes material).- For vertical surfaces, apply from bottom to top to prevent sagging. |

| Mold Making | 1. Apply release agent to the prototype (e.g., petroleum jelly for wax models).2. Pour silicone over the prototype (tilt the mold frame to reduce bubbles).3. Cure fully before demolding. | – For complex prototypes, use a split mold design (avoids tearing).- Extend curing time by 50% for thick molds (>10mm). |

| Electronic Potting | 1. Place the component (e.g., LED driver) in a potting box.2. Pour silicone to fully cover the component (1–2mm extra for protection).3. Cure at room temperature or accelerate with heat. | – Use a low-viscosity grade (flows into small component gaps).- Avoid trapping air around sensitive parts (e.g., capacitors). |

4.4 Curing & Post-Processing

- Curing Conditions:

- Room-temperature curing: 24–48 hours (condensation silicone: 12–24 hours; additive silicone: 24–48 hours).

- Accelerated curing: Heat at 60–100°C (reduces time by 50%, e.g., 24 hours → 12 hours). Do not exceed 120°C (may cause brittleness).

- Post-Processing:

- After curing, trim excess silicone with a sharp knife. For food-grade applications, wash the surface with warm soapy water and air-dry (removes any residual curing agents).

5. Critical Precautions to Avoid Failures

Even high-quality high-temperature silicone fails if misused. Follow these rules:

- Contamination Control:

- Additive (platinum-cure) silicone is sensitive to sulfur, tin, and certain oils (e.g., motor oil)—keep it away from rubber gloves, lubricants, or sulfur-containing materials (ruins curing).

- For condensation silicone, avoid contact with copper or brass (byproducts cause corrosion).

- Temperature Limits:

- Do not exceed the silicone’s continuous use temperature (e.g., a 300°C grade should not be used long-term at 350°C). Short bursts of peak temperature are safe only if specified by the manufacturer.

- Storage:

- Unopened silicone: Store in a cool, dry place (15°C–25°C) away from direct sunlight. Shelf life: 6–12 months (additive silicone); 12–24 months (condensation silicone).

- Opened silicone: Seal tightly after use—moisture absorption degrades performance.

- Safety:

- Work in a well-ventilated area (condensation silicone releases mild fumes during curing).

- Wear nitrile gloves and safety goggles (uncured silicone may irritate skin/eyes).

6. Yigu Technology’s Perspective on High-Temperature Silicone

At Yigu Technology, we’ve seen high-temperature silicone solve critical challenges for clients—from automotive manufacturers to food processors. A common mistake we address is choosing the wrong curing type: one client used condensation silicone for a precision semiconductor mold, resulting in 2% shrinkage (ruining part fit). We switched them to additive silicone (0.3% shrinkage), which fixed the issue and reduced rework costs by 40%. For food-grade projects, we always recommend platinum-cure variants (FDA-compliant, no odor) over condensation types. We also emphasize vacuum degassing for mold applications—this eliminates 95% of bubbles that cause leaks in high-temperature seals. High-temperature silicone isn’t just a material—it’s a reliability tool; selecting the right grade and following proper application steps ensures long-term performance, even in extreme environments.

7. FAQ: Common Questions About High-Temperature Silicone

Q1: Will high-temperature silicone harden or become brittle in cold environments (e.g., -60°C)?

A1: High-temperature silicone retains flexibility down to -60°C—unlike standard rubber, which becomes brittle below 0°C. It may feel slightly stiffer in cold temperatures but returns to full elasticity when warmed to room temperature. For example, a high-temperature silicone O-ring for a freezer-to-oven conveyor belt remains functional at -40°C and 280°C without cracking.

Q2: Can I paint or bond high-temperature silicone to other materials (e.g., metal, plastic)?

A2: Yes, but use compatible products:

- Painting: Use silicone-specific high-temperature paints (e.g., silicone-based enamel) that withstand 300°C+—standard paints peel or burn.

- Bonding: Use silicone adhesives (not epoxy or super glue, which don’t adhere to silicone). For metal bonding, choose a high-temperature silicone adhesive with a peel strength of ≥5 N/cm.

Q3: How do I verify if a high-temperature silicone is food-safe for baking molds?

A3: Check for two key certifications:

- FDA 21 CFR 177.2600: Ensures no harmful chemicals leach into food.

- LFGB (EU): For European markets—confirms compliance with food contact regulations.

Always ask the manufacturer for a certificate of compliance; avoid using non-certified silicone (even if labeled “high-temperature”) for food applications.