In CNC machining workshops—whether producing automotive engine components or medical device parts—the working hours of CNC machining directly affect production schedules, labor costs, and order delivery times. This key metric isn’t random; it depends on a mix of product design, equipment performance, process strategies, and operational details. This article breaks down the core influencing factors, step-by-step evaluation methods, typical scenario optimizations, and solutions to common misunderstandings, helping you accurately calculate and efficiently reduce machining hours.

1. What Are the Core Influencing Factors of CNC Machining Working Hours?

CNC machining hours are shaped by four interconnected categories, each with specific sub-factors that can extend or shorten cycle times. Below is a detailed breakdown with quantifiable impacts:

1.1 Product Design Features (Account for 30-40% of Total Hours)

Design complexity directly increases tool path difficulty and processing steps.

| Design Factor | Impact on Working Hours | Real-World Example | Optimization Tip |

| Shape Complexity | Non-standard surfaces, thin-walled structures, or deep narrow grooves add 20-50% to hours vs. simple blocks | Aviation supports with complex ribs need 5-axis linkage machining (8-12 hours/part) vs. 2-3 hours for simple brackets | Simplify non-critical contours; Avoid unnecessary deep grooves (>10x diameter) |

| Accuracy & Surface Requirements | High-precision features (e.g., IT6-level holes) require 2-3x more time for semi-finishing + testing | Mirror-polished mold inserts need reduced feed rates (50-100mm/min) vs. 300-500mm/min for Ra 6.3μm surfaces | Use multi-step finishing (rough → semi-finish → finish) instead of repeated corrections |

| Material Type | Difficult-to-cut materials slow processing by 30-60% vs. easy-to-cut metals | Stainless steel (304) requires 80-120m/min cutting speed vs. 300-500m/min for aluminum alloys | Choose carbide tools for steel; Use high-speed steel (HSS) only for low-volume soft metal parts |

| Feature Quantity & Layout | Dense small holes/threads add 15-30% time due to tool changes | A 50mm×50mm aluminum plate with 20 M3 threads needs 40+ minutes (vs. 15 minutes for 5 threads) | Group same-diameter features to reduce tool changes; Use multi-spindle heads for hole arrays |

1.2 Machine Tools & Process Conditions (Account for 25-35% of Total Hours)

Equipment capabilities and setup efficiency determine how quickly parts can be machined.

| Condition Factor | Impact on Working Hours | Key Parameters | Cost-Benefit Note |

| Equipment Performance | High-rigidity machines cut roughing time by 20-30% vs. older models | A new vertical machining center (VMC) with 12,000rpm spindle finishes a steel block in 4 hours vs. 6 hours on a 8,000rpm VMC | Upgrading spindles (from 8k to 15k rpm) saves 15-25% on thin-walled part hours |

| Tool Configuration | Insufficient tool magazine capacity adds 10-20% manual tool change time | A 24-tool magazine handles a 5-operation part in 3 hours vs. 4 hours with an 8-tool magazine (needs 2 manual changes) | Prioritize tools for high-frequency operations; Use tool presetters to cut setup time |

| Clamp System | Quick-clamp tools reduce downtime by 40-60% vs. manual alignment | A hydraulic vise clamps a part in 2 minutes vs. 10 minutes for manual bolt clamping | Adopt zero-point positioning systems for batch production (repeat setup <1 minute) |

| Cooling & Lubrication | Poor cooling adds 15-25% time due to sticky chips or tool wear | Dry cutting aluminum causes 2-3x more tool changes (each taking 5-10 minutes) vs. high-pressure mist cooling | Use water-soluble coolants for steel; Air-oil mist for aluminum (reduces chip cleanup) |

1.3 Procedures & Operation Strategies (Account for 20-25% of Total Hours)

Smart process planning eliminates redundant steps and optimizes tool paths.

| Strategy Factor | Impact on Working Hours | Practical Example | Common Mistake |

| Tool Path Planning | Ring cutting is 20-30% faster than row cutting for large surfaces | A 200mm×200mm aluminum plate takes 30 minutes with ring cutting vs. 45 minutes with row cutting | Avoid Z-axis straight down (causes tool shock); Use spiral down for deep cavities |

| Margin Allocation | Overly large roughing margins (e.g., >5mm) double finishing time | A steel part with 3mm roughing margin takes 2 hours to finish vs. 1 hour with 1.5mm margin | Follow “rough 70-80% of material, finish 20-30%” for balance |

| Exception Handling | Unplanned downtime (e.g., tool breakage) can take up 10-15% of total hours | A missed emergency retraction space causes a tool strike, adding 2-3 hours of repair time | Reserve 5-10mm retraction space; Use collision detection software |

2. How to Evaluate CNC Machining Working Hours Step-by-Step?

Accurate hour evaluation requires combining theoretical calculations with practical measurements. Below is a 3-stage method to avoid guesswork:

2.1 Stage 1: Basic Data Collection (Lays the Foundation)

Gather key information to set calculation parameters.

| Data Type | Collection Method | Critical Output |

| Drawing Analysis | Review tolerance zones, shape/position tolerances, and heat treatment requirements | Divide processing into stages (e.g., pre-heat treatment roughing → post-heat treatment finishing) |

| Equipment Matching | Select machine tools by part size (e.g., gantry for >1m parts, VMC for <1m parts) | Calculate non-cutting time (e.g., gantry machines move at 10m/min vs. 20m/min for small VMCs) |

| Tool List Preparation | List tool type, diameter (D), and number of teeth; Calculate cutting speed (Vc) | Use formula: Spindle speed (S) = (Vc×1000)/(π×D) (e.g., Vc=300m/min for aluminum, D=10mm → S=9549rpm) |

2.2 Stage 2: Segmented Timing & Verification (Validates Theoretical Data)

Test and adjust calculations with real machine runs.

- Empty Running Test: Lock the spindle and run the program. Record:

- Axis movement time (e.g., X/Y/Z axis travel time between features);

- Rapid positioning frequency (each positioning adds 2-5 seconds);

- Redundant empty strokes (e.g., unnecessary tool returns to home).

Outcome: Eliminate 5-10% of non-cutting time by optimizing tool path order.

- First Piece Trial Cutting: Run actual machining and log:

- Start/end time for each process (roughing, semi-finishing, finishing);

- Tool change intervals (each manual change takes 3-8 minutes, automatic takes 10-30 seconds);

- Spindle start/stop delays (add 2-3 seconds per cycle).

Outcome: Adjust theoretical parameters (e.g., reduce feed rate if tool vibration occurs).

- Abnormal Time Statistics: Track non-value-added time:

- Tool replacement (5-15 minutes per broken tool);

- Program debugging (10-20 minutes for complex parts);

- Measurement waiting (5-10 minutes for CMM checks).

Outcome: These times often account for 10-20% of total hours—plan buffers accordingly.

2.3 Stage 3: Experience Coefficient Modification (Ensures Practicality)

Adjust theoretical hours to account for real-world variables.

| Modification Factor | Adjustment Ratio | Reason |

| Safety Buffering | Add 5-15% to theoretical hours | Copes with material hardness fluctuations (e.g., ±10% in aluminum alloy hardness) or tool wear |

| Batch Effect | First part: +30-50% (includes tool setting/program verification); Subsequent parts: -10-20% | The first part of a batch takes 4 hours vs. 2.5-3 hours for parts 2-100 |

| Environmental Compensation | Add 5-10% in extreme temperatures (>30°C or <10°C) | Shop floor heat causes machine thermal deformation, requiring more in-line measurements |

3. How to Optimize Working Hours in Typical CNC Machining Scenarios?

Different part types have unique time-consuming pain points—targeted optimizations deliver quick results. Below are two common scenarios:

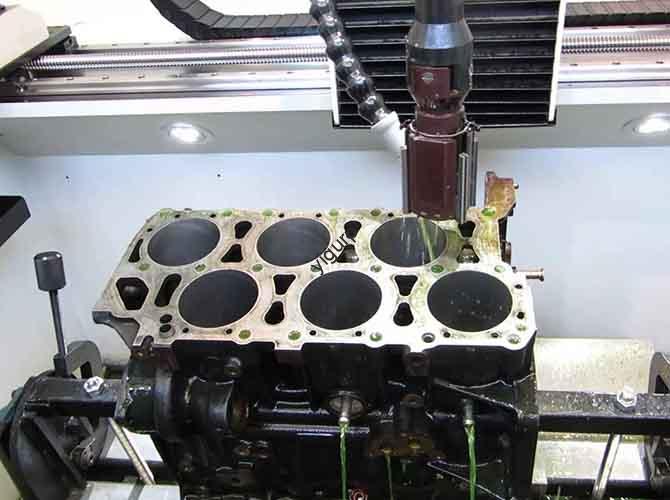

3.1 Scenario 1: Aluminum Alloy Gearbox Housing

- Features: Thin-walled cavity (2-3mm thickness) + 4 mounting surfaces + 12 M8 threaded holes.

- Key Time-Consuming Points:

- Roughing uses a large-diameter face mill (φ50mm) but requires 8-10 passes to remove material;

- Finishing needs a long-handled small-diameter tool (φ6mm) to clean cavity roots (slow feed rate: 80-120mm/min);

- Threaded holes have aluminum chip clogging, requiring 3-5 blows per hole.

- Optimization Results:

| Optimization Measure | Time Saved | New Total Hours |

| Switch to honeycomb lightweight cutterhead (φ63mm) | 20-25% (reduces passes to 5-6) | From 5 hours to 4 hours |

| Pre-coat tool with anti-stick coating (e.g., TiAlN) | 15-20% (speeds root cleaning to 150-200mm/min) | From 4 hours to 3.3 hours |

| Use air blow + vacuum suction during threading | 10-15% (eliminates re-blowing) | From 3.3 hours to 2.9 hours |

3.2 Scenario 2: Stainless Steel Medical Surgical Instrument

- Features: Micron-level tolerance (±0.005mm) + mirror surface (Ra ≤0.2μm) + complex curve contours.

- Key Time-Consuming Points:

- Engraving complex curves at slow speed (50-80mm/min) to avoid surface scratches;

- Manual grinding removes tool marks (takes 30-45 minutes per part);

- 3D inspection (CMM) is done 3x per part (total 20-30 minutes).

- Optimization Results:

| Optimization Measure | Time Saved | New Total Hours |

| Introduce ultrasound-assisted cutting (20-50kHz vibration) | 30-40% (speeds engraving to 120-150mm/min) | From 8 hours to 6 hours |

| Use diamond-plated tools (Ra ≤0.1μm) for one-pass finishing | 40-50% (eliminates manual grinding) | From 6 hours to 4 hours |

| Combine in-line laser measurement with final CMM check | 50-60% (reduces inspection to 10-12 minutes) | From 4 hours to 3.7 hours |

4. What Are Common Misunderstandings About CNC Machining Working Hours?

Misconceptions lead to inaccurate planning and wasted resources. Below are two key myths and their solutions:

| Misunderstanding | Reality | Practical Countermeasure |

| “Same drawing = same working hours” | Equipment generation differences matter: Old CNC systems (≥10 years) process complex G-code 20-30% slower than new systems (≤5 years) | Establish an enterprise-level database: Store hours by material, equipment model, and process; Update monthly |

| “Ignore non-cutting time” | Non-cutting time (tool changes, tool setting, measurement) accounts for 25-40% of total hours (not 5-10% as assumed) | Use automatic tool changers (ATCs) for >5-tool parts; Adopt quick-setup fixtures (e.g., zero-point systems) |

5. Yigu Technology’s Perspective on Working Hours of CNC Machining

At Yigu Technology, we see working hours of CNC machining as a “mirror of process efficiency”—it reflects not just speed, but also the rationality of design, equipment, and operations. Our data shows 60% of hour waste comes from “hidden inefficiencies” (e.g., poor tool path planning, redundant inspections) rather than equipment speed limits.

We recommend a “digital-driven optimization” approach: For batch parts, we use CAM software to simulate tool paths (cutting 10-15% of empty time) and MES systems to track real-time machine data; For complex parts, we apply machine learning to historical data (e.g., 10,000+ part records) to auto-recommend optimal parameters (e.g., feed rate, spindle speed). By combining standardized processes (for similar parts) and intelligent monitoring, we help clients reduce average working hours by 20-30% while maintaining quality.

6. FAQ: Common Questions About Working Hours of CNC Machining

Q1: Can I use the same hour calculation formula for different materials?

No. The core formula (cutting time = material volume / (feed rate × spindle speed × tool efficiency)) must be adjusted for material hardness. For example, stainless steel (304) needs a 0.6-0.8 efficiency coefficient vs. 1.0 for aluminum alloy—ignoring this leads to 20-40% underestimation of hours.

Q2: How much time does an automatic tool changer (ATC) save compared to manual tool changes?

An ATC takes 10-30 seconds per tool change vs. 3-8 minutes for manual changes. For a part needing 8 tools, this saves 20-60 minutes per part—critical for batches >50 parts. For small batches (<10 parts), manual changes may be cheaper (no ATC setup time).

Q3: Why do hours increase for parts with thin walls (<3mm) even if they’re simple in shape?

Thin walls require reduced cutting force (to avoid deformation), which means slower feed rates (50-70% of standard) and smaller depth of cut (0.1-0.3mm vs. 0.5-1mm). For example, a 2mm aluminum wall takes 40 minutes to finish vs. 25 minutes for a 5mm wall—even with the same area.