Die casting hot joints are silent quality killers in metal forming—they arise from local cooling delays in castings and trigger a chain of defects, from surface dimples to catastrophic fatigue failure. For manufacturers producing critical parts (e.g., automotive brake calipers, hydraulic valves), ignoring hot joints can lead to costly recalls, production halts, and reputational damage. This article dives deep into the formation mechanism of hot joints, their multi-stage quality impacts, and a systematic solution framework—drawing on real-world cases and technical data to help you eliminate hot joint risks at every production stage.

1. What Are Die Casting Hot Joints? Definition & Core Characteristics

Before solving the problem, it’s critical to clarify what die casting hot joints are and how to identify them. This section uses a definition + key traits structure, with critical terms highlighted for clarity.

1.1 Fundamental Definition

Die casting hot joints refer to localized areas in castings where heat dissipation is blocked due to structural design or process constraints, resulting in unbalanced solidification. Unlike normal casting areas (which follow a “top-down” sequential solidification law), hot joints remain at high temperatures longer—causing molten metal to solidify last and leaving internal defects like shrinkage, porosity, or coarse grains.

Their essence is a heat accumulation effect: When castings have thick-walled concentrations (e.g., bosses, multi-rib intersections) or enclosed structures (e.g., deep narrow grooves, closed cavities), heat in these areas cannot escape quickly. For example, the water channel intersection of an engine block forms a 3D “heat trap”—even with optimized gating systems, it retains heat 2-3x longer than surrounding thin-walled areas.

1.2 Key Identification Traits

You can recognize hot joints through three observable signs (both visual and microscopic):

| Identification Dimension | Specific Traits | Detection Method |

| Surface Features | Irregular depressions (“dimples”) with rough edges; often located at thick-walled intersections or boss roots | Naked eye inspection (after sandblasting) or 10x magnification lens |

| Microstructure | Coarse columnar grains (vs. fine equiaxed grains in normal areas); low-melting-point phases enriched at grain boundaries | Metallographic analysis (sample etching with 5% nitric acid solution) |

| Mechanical Performance | 15-30% lower tensile strength than normal areas; prone to cracking under alternating loads | Tensile testing (sample taken from suspected hot joint area) or ultrasonic flaw detection |

2. Formation Mechanism of Die Casting Hot Joints: A Step-by-Step Breakdown

Hot joints form due to a combination of structural design flaws and process parameter mismatches. This section uses a causal chain structure to explain how heat accumulation leads to defects, with a real-world scenario example.

2.1 Three Stages of Hot Joint Formation

- Heat Accumulation Stage (During Filling)

When molten metal fills the mold, thick-walled or enclosed areas trap heat. For instance, a 20mm-thick boss surrounded by 5mm thin walls absorbs 4x more heat than the thin walls. This creates a temperature difference of 80-120°C between the hot joint and normal areas—breaking the sequential solidification sequence.

- Defect Genesis Stage (During Solidification)

As the casting cools, the hot joint (last to solidify) faces two critical issues:

- Shrinkage Failure: Molten metal in the hot joint shrinks during solidification, but there’s no additional metal to replenish it (risers are too far or solidify early). This forms microscopic shrinkage voids (0.1-0.5mm in diameter).

- Gas Entrapment: High temperatures reduce the solubility of hydrogen in the metal—dissolved hydrogen precipitates as bubbles, which are frozen in the hot joint (since it solidifies last). These bubbles form porosity, reducing the casting’s compactness.

- Defect Stabilization Stage (After Cooling)

Once fully solidified, the hot joint retains internal defects (shrinkage + porosity) and a coarse grain structure. This makes it a “weak zone”—during machining or service, it’s prone to further damage (e.g., tool chipping during cutting, crack initiation under load).

2.2 Typical Scenario Example

An automotive parts manufacturer produced aluminum brake caliper brackets with a 15mm-thick mounting boss (hot joint area). During production:

- The boss retained heat for 22 minutes (vs. 8 minutes for 6mm thin walls), leading to shrinkage in the core.

- Machining revealed “vibrating knife patterns” (tool chipping from uneven hardness in the hot joint).

- During road testing, alternating brake loads caused cracks to start from the shrinkage area—ultimately leading to a recall of 10,000 units.

3. Quality Impact of Hot Joints: A Cascading Hazard Chain

Hot joints don’t just cause surface defects—they trigger a step-by-step amplification of quality risks, from machining issues to functional failure. This section uses a 递进 structure to outline their multi-stage 危害,with specific data on cost impacts.

3.1 Stage 1: Machining Problems (Direct Cost Increase)

Hot joints have uneven hardness (due to coarse grains and shrinkage), which disrupts machining:

- Tool Wear: Cutting tools encounter soft shrinkage areas and hard grain boundaries alternately—accelerating tool wear by 50-80%. For example, a carbide end mill that lasts 500 parts on normal areas only lasts 200 parts on hot joint-rich brackets.

- Surface Defects: Vibrating knife patterns or chipped edges require rework (e.g., manual grinding), adding 10-15 minutes of labor per part. For a 10,000-unit order, this translates to 1,600+ extra labor hours.

3.2 Stage 2: Mechanical Performance Degradation (Reliability Risk)

Hot joints weaken the casting’s structural integrity:

- Strength Loss: Tensile strength drops by 15-30%—an aluminum A356 casting with a hot joint has a tensile strength of 220MPa (vs. 320MPa in normal areas), failing to meet automotive safety standards.

- Fatigue Failure: Under alternating loads (e.g., engine vibration, brake cycles), shrinkage in hot joints acts as crack initiation points. Fatigue life is reduced by 60-70%—a hydraulic valve with a hot joint may fail after 50,000 cycles (vs. 150,000 cycles for defect-free valves).

3.3 Stage 3: Functional Failure (Safety & Recall Risks)

For parts with special requirements (e.g., pressure tightness, high-temperature resistance), hot joints cause catastrophic failures:

- Leakage: Microcracks in hot joints of hydraulic parts (e.g., cylinder blocks) lead to pressure loss. A study by the Automotive Industry Action Group (AIAG) found that 70% of hydraulic leakage issues in die cast parts originate from hot joints.

- Recall Costs: As seen in the brake caliper example, hot joint-related recalls cost \(50-\)200 per unit (including part replacement, labor, and legal fees). A 10,000-unit recall can exceed $1 million in total losses.

4. Systematic Solutions for Die Casting Hot Joints: 4-Layer Prevention Framework

Eliminating hot joints requires a “design-process-mold-monitoring” integrated approach—not just post-fix remediation. Below is a 4-layer solution framework, with actionable steps and parameter ranges.

4.1 Layer 1: Design-End Pre-Intervention (Root Cause Prevention)

Fixing hot joints starts with design—avoid creating heat traps in the first place. Key strategies:

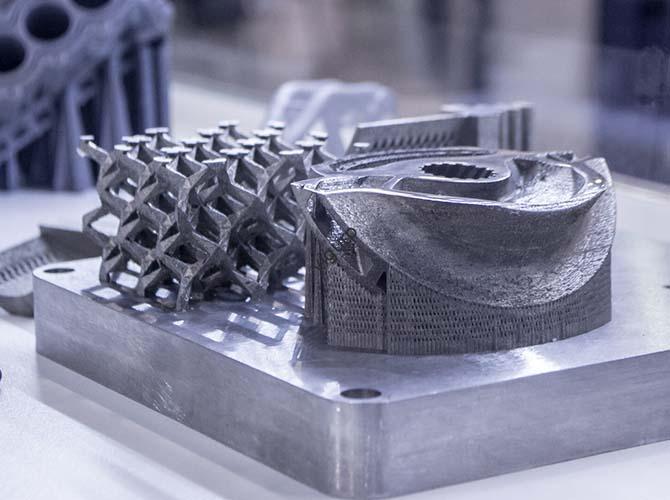

- Energy Dispersion Design: Decompose solid thick-walled structures into grid-like ribs. For example, replace a 20mm solid gearbox boss with a 10mm-thick honeycomb stiffener structure—reduces heat accumulation by 60%.

- Gradient Thickness Transition: Use a 1:10+ taper transition at thick-thin wall intersections (e.g., a 15mm boss connects to a 5mm wall via a 100mm-long taper). This eliminates sudden temperature jumps.

- Active Heat Drainage: Add overflow grooves at predicted hot joint locations (e.g., boss roots). The overflow groove acts as a “heat sink”—it collects excess molten metal and dissipates heat, reducing hot joint temperature by 30-40%.

4.2 Layer 2: Process Parameter Optimization (Precise Heat Control)

Adjust die casting parameters to balance heat distribution:

| Parameter Category | Optimization Measures | Target Value |

| Injection Profile | Adopt “slow-fast-slow” three-stage injection; apply 10-15% higher pressure at the end of filling (to squeeze hot joint areas) | Slow stage: 0.5-1.0 m/s; fast stage: 3-4 m/s; final pressure: 120-150 MPa |

| Temperature Control | Use mold partition cooling: Embed cooling water pipes 8-12mm from the hot joint mold core; control temperature difference within ±5°C | Mold temperature (hot joint area): 200-230°C (aluminum); 250-280°C (cast iron) |

| Melt Purification | Degas molten metal with argon for 12-18 minutes; filter with a 50μm ceramic filter (second purification) | Hydrogen content: <0.12ml/100g Al; oxide inclusion content: <0.05% |

4.3 Layer 3: Mold Structure Enhancement (Heat Dissipation & Durability)

Optimize mold design to accelerate heat escape from hot joints:

- Inlaid Mold Cores: Make hot joint-related mold cores into independent modules (e.g., H13 steel with nitriding treatment). These modules can be cooled separately and replaced easily (extending mold life by 30%).

- Elastic Deformation Compensation: Add prestressed tie rods to large molds (e.g., 20-25mm diameter for 1m-wide molds). This offsets thermal expansion of the mold during high-temperature operation—preventing gaps that trap heat.

- Serpentine Exhaust Grooves: Add 0.1-0.15mm deep, 5-8mm wide serpentine exhaust grooves near hot joints. The negative pressure from molten metal impact sucks out trapped gas and heat—reducing porosity by 50%.

4.4 Layer 4: Real-Time Monitoring & Verification (Quality Assurance)

Use advanced testing to detect and correct hot joints early:

- Real-Time Temperature Tracking: Embed K-type thermocouples in hot joint mold cores (1-2mm from the cavity surface). Transmit data wirelessly to draw cooling curves—any area with cooling time >2x normal areas is flagged as a hot joint risk.

- X-Ray CT Inspection: Conduct CT scans on trial production samples (10-20 samples per batch). Quantify shrinkage volume—reject batches where hot joint shrinkage exceeds 1% of the area.

- Stress Simulation: Use ProCAST software to simulate the casting’s temperature field during solidification. Predict hot joint locations and adjust designs (e.g., add cooling channels) before mold production—cutting trial-and-error time by 40%.

5. Practical Case Study: Eliminating Hot Joints in Electronic Equipment Frames

A manufacturer producing aluminum electronic equipment frames (A356 alloy) faced hot joint issues in 8mm-thick mounting lugs—leading to 15% scrap rate and 20% lower tensile strength. Here’s how they solved it using the 4-layer framework:

- Design Adjustment: Replace solid lugs with hollow weight-reducing structures (retaining 5mm wall thickness) + 2mm-wide ribs. This reduced heat accumulation by 55%.

- Process Optimization: Increase final injection pressure to 140MPa (from 120MPa) and extend holding time by 3 seconds. Cool the lug mold core with a dedicated water channel (flow rate 2L/min).

- Mold Upgrade: Add a serpentine exhaust groove (0.12mm deep) at the lug root and use an inlaid mold core (nitrided H13 steel).

- Monitoring: Embed a thermocouple in the lug core—ensure cooling time is <10 minutes (vs. 18 minutes before).

Results: Hot joint scrap rate dropped to <2%, tensile strength recovered to 310MPa (meets design requirements), and production efficiency increased by 12% (fewer reworks).

6. Yigu Technology’s Perspective on Die Casting Hot Joints

At Yigu Technology, we believe solving hot joints is about “predicting, not fixing”—many manufacturers waste resources on post-processing defective parts instead of addressing root causes in design. The key is to treat hot joints as a “systemic issue” rather than a random defect.

We recommend integrating DFM (Design for Manufacturability) reviews into the early development stage: Our engineers use simulation tools to identify hot joint risks in 3D models and propose rib optimization or cooling channel designs—saving clients 30-50% in mold revision costs. For mass production, we also advocate combining thermocouple monitoring with AI algorithms—predicting hot joint formation 1-2 cycles in advance and adjusting parameters automatically.

Ultimately, eliminating hot joints requires balancing “heat-time-pressure” in die casting. By unifying design, process, and monitoring, manufacturers can achieve near-zero hot joint defects and ensure part reliability.

7. FAQ: Common Questions About Die Casting Hot Joints

Q1: Can hot joints be repaired after casting, or must defective parts be scrapped?

Small, non-critical hot joints (e.g., non-load-bearing appearance parts) can be repaired via argon arc welding (use matching alloy filler, current 80-100A) + grinding. However, load-bearing or pressure-tight parts (e.g., brake calipers, hydraulic valves) should be scrapped—repairs can’t restore original strength and may hide internal defects. It’s more cost-effective to prevent hot joints than to repair them.

Q2: How to distinguish hot joint porosity from other types of porosity (e.g., gas porosity from poor degassing)?

Hot joint porosity has three unique traits: 1. Location: Concentrated at thick-walled intersections or bosses (vs. random distribution of gas porosity). 2. Shape: Irregular shrinkage voids (vs. spherical gas bubbles). 3. Microstructure: Surrounded by coarse grains (gas porosity has no grain size correlation). Use metallographic analysis or CT scans to confirm—hot joint porosity often has a “dendritic” distribution along grain boundaries.

Q3: Do hot joints affect heat treatment of die cast parts?

Yes—hot joints increase the risk of cracking during heat treatment. The coarse grains and internal stress in hot joints cause uneven expansion when heated (e.g., during T6 solution treatment at 530°C). For parts with hot joints, either: 1. Fix the hot joint first (via welding or design changes), or 2. Use a slower heat treatment ramp rate (50°C/hour vs. 100°C/hour) to reduce stress. However, the best approach is to eliminate hot joints before heat treatment—this ensures uniform mechanical properties.