If you’re in a field that demands ultra-small, high-precision parts—like medical device design, aerospace engineering, or electronics manufacturing—you’ve probably asked: What exactly is CNC micro machining, and why is it critical for my projects? Simply put, CNC micro machining is a computer-controlled manufacturing process that creates tiny, intricate components with tolerances as tight as ±0.001 mm. Unlike traditional machining, which struggles with small-scale details, it uses specialized tools and software to carve, mill, or turn materials into micro-sized parts—think components smaller than a grain of rice, but with exacting accuracy. Whether you’re building a miniaturized sensor or a surgical instrument, this technology turns complex micro-designs into tangible, reliable parts. Below, we’ll break down everything you need to know to leverage it effectively.

What Sets CNC Micro Machining Apart from Traditional Machining?

To understand CNC micro machining’s value, it helps to compare it to the traditional machining you might be familiar with. The key differences lie in scale, precision, tooling, and application—and these gaps are why micro machining is irreplaceable for modern miniaturized products.

| Aspect | Traditional CNC Machining | CNC Micro Machining |

| Part Size | Typically ≥ 10 mm | Often ≤ 5 mm (some parts < 1 mm) |

| Tolerance Range | ±0.01 mm to ±0.1 mm | ±0.0001 mm to ±0.001 mm |

| Tool Diameter | ≥ 3 mm | ≤ 1 mm (down to 0.01 mm) |

| Spindle Speed | Up to 20,000 RPM | 30,000–150,000 RPM |

| Ideal Applications | Automotive parts, large brackets | Medical needles, micro sensors |

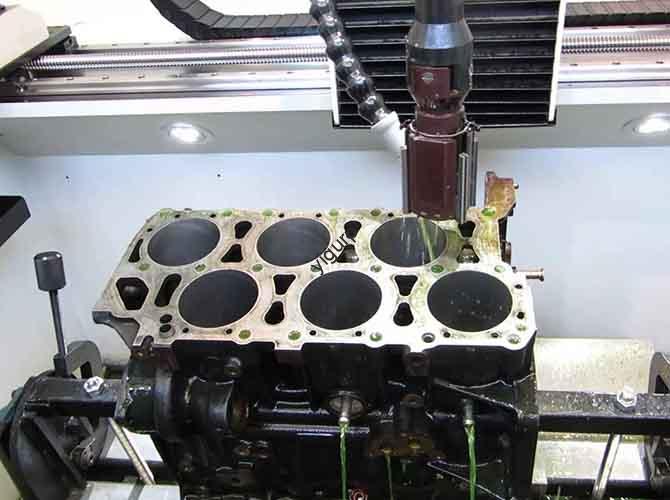

A real-world example highlights this difference: A client in the automotive industry once used traditional machining to make a 20 mm engine component with a ±0.05 mm tolerance—it worked perfectly. But when they needed a 2 mm sensor for a hybrid vehicle, traditional tools couldn’t reach the internal grooves without breaking, and the tolerance was off by 0.02 mm (enough to make the sensor fail). Switching to CNC micro machining solved both issues: a 0.5 mm tool carved the grooves cleanly, and the final part hit the ±0.001 mm tolerance. That’s the gap micro machining fills.

Key Materials Used in CNC Micro Machining (and How to Choose Yours)

Not all materials work equally well with CNC micro machining—success depends on choosing a material that balances machinability, strength, and your project’s needs. Below are the most common options, along with their best uses and critical considerations.

1. Metals and Alloys

- Stainless Steel (316L, 17-4 PH): Ideal for medical and aerospace parts because of its corrosion resistance and strength. For example, a surgical device manufacturer we worked with used 316L to make micro-forceps (2 mm tip width) that could withstand repeated sterilization. Note: Stainless steel is harder than aluminum, so it requires slower cutting speeds (40,000–60,000 RPM) to avoid tool wear.

- Titanium (Grade 5): Lightweight and biocompatible, making it perfect for dental implants or aerospace micro-components. One client used Grade 5 to create 3 mm-wide turbine blades for a mini drone—titanium’s strength-to-weight ratio kept the blades from bending at high speeds.

- Aluminum (6061): Easy to machine (fast speeds, 80,000–100,000 RPM) and cost-effective for electronics, like micro-heat sinks. It’s less durable than steel or titanium, so avoid it for high-stress parts.

2. Polymers and Plastics

- PEEK (Polyether Ether Ketone): Heat-resistant and biocompatible, used in spinal implants or micro-valves. A medical client needed a 1.5 mm PEEK valve for a drug delivery device—micro machining’s precision ensured the valve opened and closed at exactly 0.5 psi pressure.

- Acrylic (PMMA): Transparent and low-cost, great for micro-lenses or optical components. However, it’s brittle—machining too quickly can cause cracking, so we recommend 50,000–70,000 RPM for acrylic parts.

3. Ceramics (Alumina, Zirconia)

- Hard and heat-resistant, but challenging to machine. Ceramics are used in micro-insulators for electronics (e.g., 0.8 mm alumina insulators for high-voltage sensors). We always use diamond-coated tools for ceramics—they reduce chipping and extend tool life by 30% compared to standard tools.

How to Choose: Start with your part’s function: If it needs to be in the human body (biocompatible), pick titanium or PEEK. If it’s for electronics (low weight, low cost), aluminum or acrylic works. For high-stress, high-temperature use, stainless steel or ceramics are better.

Core CNC Micro Machining Techniques: Which One Fits Your Project?

CNC micro machining isn’t a single process—it’s a set of techniques, each designed for specific part shapes and materials. Understanding the differences helps you pick the right method and avoid costly mistakes.

1. Micro Milling

- What it does: Uses a rotating micro-tool (0.01–1 mm diameter) to remove material from a workpiece, creating 3D shapes like slots, holes, or complex contours. It’s like “carving” a tiny sculpture.

- Best for: Parts with intricate 3D features, such as micro-gears (1 mm diameter with 0.1 mm teeth) or sensor housings.

- Real case: A consumer electronics client needed 0.5 mm-wide slots in a 2 mm aluminum housing for a smartwatch sensor. Micro milling with a 0.3 mm carbide tool created the slots with ±0.0005 mm accuracy—something no other technique could do.

- Pro tip: Use high-speed spindle micro milling (100,000+ RPM) for hard materials like stainless steel—it reduces vibration, which is key for avoiding tool breakage.

2. Micro Turning

- What it does: Spins the workpiece while a stationary tool cuts it, creating cylindrical parts like micro-shafts or needles. Think of it as “shaping a pencil with a knife” but on a micro scale.

- Best for: Symmetrical, cylindrical parts—e.g., 0.2 mm diameter medical needles or 1 mm micro-shafts for small motors.

- Key stat: Micro turning can achieve surface finishes as smooth as Ra 0.02 μm (Ra = roughness average), which is critical for medical needles (rough surfaces can irritate tissue).

- Challenge: Workpieces are so small (sometimes <1 mm) that they can bend during spinning. To fix this, we use “live tooling” (tools that move with the workpiece) and slow down the rotation speed for thin parts.

3. Micro Drilling

- What it does: Creates ultra-small holes (as small as 0.005 mm) in materials—smaller than the diameter of a human hair (≈0.05 mm).

- Best for: Parts that need tiny fluid or electrical channels, like 0.01 mm holes in a PEEK micro-fluidic chip for lab-on-a-chip devices.

- Common mistake: Using a drill bit that’s too sharp. Sharp bits can “walk” (drift off center) on soft materials like plastic. Instead, use a slightly rounded bit and lower spindle speed (30,000–50,000 RPM) for accuracy.

Critical Factors for Successful CNC Micro Machining (Avoid These Mistakes)

Even with the right technique and material, micro machining can fail if you overlook key details. Below are the most important factors to master, based on our 10+ years of fixing failed projects.

1. Tolerance Control: Why “Close Enough” Isn’t Enough

Tolerances in micro machining are measured in microns (1 micron = 0.001 mm)—and even a 1-micron error can ruin a part. For example, a client once ordered 1 mm micro-gears for a mini robot with a ±0.001 mm tolerance. Their first supplier delivered gears with a ±0.002 mm error—when assembled, the gears didn’t mesh, and the robot’s motor burned out.

How to ensure tight tolerances:

- Use high-precision CNC machines (with linear guides that have ≤0.0005 mm backlash).

- Calibrate tools daily—even a 0.0001 mm tool wear can throw off tolerances.

- Choose materials with low thermal expansion (like Invar, a nickel-iron alloy) if your part will be used in temperature-changing environments (e.g., aerospace).

2. Tool Selection: The Right Tool Makes All the Difference

Micro tools are fragile—using the wrong one is the #1 cause of broken tools and wasted parts. Here’s what to remember:

- Material: Carbide tools work for most metals; diamond-coated tools for ceramics/plastics; high-speed steel (HSS) for soft aluminum (cheaper than carbide).

- Coating: TiAlN (titanium aluminum nitride) coatings reduce friction and extend tool life by 50% for steel parts. For titanium, use TiSiN (titanium silicon nitride)—it resists heat better.

- Size: Never use a tool smaller than 10% of the part’s smallest feature. For example, if you’re making a 0.5 mm hole, use a 0.3 mm tool (not 0.05 mm)—smaller tools break easily.

3. Vibration Management: The Hidden Enemy of Precision

Vibration (even from a nearby air compressor) can cause micro tools to “chatter,” leaving rough surfaces or missing features. We once had a client whose micro-milled sensor housings had inconsistent slot widths—turns out, their machining room was next to a printing press. Moving the machine to a quieter area fixed the issue.

How to reduce vibration:

- Mount the CNC machine on a vibration-dampening base (rubber or granite).

- Use shorter tools—long tools vibrate more. For example, a 5 mm-long tool vibrates 3x less than a 10 mm-long tool.

- Keep spindle speeds within the “sweet spot” for your material (e.g., 60,000–80,000 RPM for stainless steel)—too slow or too fast increases vibration.

Real-World Applications of CNC Micro Machining (Industry Examples)

CNC micro machining isn’t just a “niche” technology—it’s transforming industries by enabling products that were impossible a decade ago. Below are three industries where it’s making the biggest impact, with concrete examples.

1. Medical Device Manufacturing

The medical industry relies on micro machining for parts that must be biocompatible, precise, and small enough to enter the human body. For example:

- Surgical Robots: A leading medical device company used micro machining to make 2 mm titanium “fingers” for a robotic surgical tool. The fingers needed ±0.0005 mm tolerance to grip and suture tiny blood vessels—traditional machining couldn’t achieve this, but micro machining did.

- Drug Delivery Devices: Insulin pens use 0.1 mm PEEK micro-valves to control drug flow. We machined these valves with micro drilling (0.08 mm holes) to ensure each dose is exactly 0.5 mL—no more, no less.

Key stat: The global medical micro machining market is expected to grow from \(1.2 billion in 2023 to \)2.1 billion by 2028 (CAGR of 12.1%)—driven by demand for miniaturized surgical tools (Source: Grand View Research).

2. Aerospace and Defense

In aerospace, every gram matters—and micro machining creates lightweight, high-strength parts for drones, satellites, and missiles. For example:

- Mini Drones: A defense contractor needed 3 mm-wide turbine blades for a micro-drone (weight: 50 grams). We used titanium micro turning to make the blades, which could withstand 20,000 RPM without bending. The drone’s flight time increased by 15% because of the lightweight parts.

- Satellite Sensors: Satellites use 0.5 mm aluminum micro-heat sinks to cool sensors in space. Micro milling created the heat sinks’ tiny fins (0.1 mm thick), which maximize heat dissipation while minimizing weight.

3. Electronics and Semiconductors

As electronics get smaller (think foldable phones, wearables), micro machining makes components like micro-connectors and sensor housings. For example:

- Wearable Fitness Trackers: A tech company needed 1 mm-wide micro-connectors for a smartwatch’s heart rate sensor. We used micro milling with a 0.3 mm carbide tool to create the connectors, which transmit data with 99.9% accuracy—critical for reliable heart rate readings.

- Semiconductor Test Fixtures: Semiconductor manufacturers use 0.05 mm micro-probes to test chips. Micro drilling creates the tiny holes in the probes that conduct electricity, ensuring accurate chip testing.

Yigu Technology’s Perspective on CNC Micro Machining

At Yigu Technology, we’ve seen CNC micro machining evolve from a “specialized” service to a “must-have” for clients in medical, aerospace, and electronics. What sets successful micro machining projects apart? It’s not just about having the right machines—it’s about combining technical expertise with a deep understanding of the client’s end-use. For example, when a medical client came to us with a failed micro-needle design (their previous supplier’s needles had rough tips), we didn’t just re-machine the part—we adjusted the tool coating (switched to diamond) and slowed the spindle speed to reduce friction, resulting in smoother tips that met FDA standards. We believe the future of micro machining lies in tighter integration with 3D design software (to catch errors early) and advanced materials (like carbon fiber composites) that offer even better strength-to-weight ratios. For businesses looking to adopt micro machining, start small: Test a single part (e.g., a micro-connector) before scaling up. This lets you validate the process and avoid costly mistakes.

FAQ: Common Questions About CNC Micro Machining

1. How much does CNC micro machining cost compared to traditional machining?

CNC micro machining is typically 2–3x more expensive than traditional machining, but the cost is justified for parts that require tight tolerances or small sizes. For example, a 1 mm micro-gear might cost \(50–\)100 (vs. \(10–\)20 for a 10 mm traditional gear). The cost depends on material (titanium is more expensive than aluminum) and tolerance (±0.0001 mm costs more than ±0.001 mm).

2. What’s the smallest part CNC micro machining can make?

The smallest parts we’ve made are 0.1 mm in diameter (about the size of a dust particle)—for example, a 0.1 mm tungsten micro-probe for a semiconductor test fixture. In general, most micro machining projects focus on parts between 0.1 mm and 5 mm, as smaller parts become difficult to handle (even with specialized tools).

3. How long does a typical CNC micro machining project take?

It depends on the part’s complexity and quantity. A simple part (e.g., a 1 mm aluminum micro-shaft) with a small quantity (10–50 pieces) can take 1–2 days. A complex part (e.g., a 2 mm PEEK micro-fluidic chip with 0.01 mm holes) with a large quantity (1000+ pieces) can take 1–2 weeks. Prototyping is faster—we often deliver prototype parts in 3–5 business days.

4. Can CNC micro machining work with flexible materials like rubber?

It’s possible, but challenging. Flexible materials like rubber or silicone can stretch or deform during machining, which ruins precision. If you need a micro part from a flexible material, we recommend using micro molding (for large quantities) or coating the material with a temporary stiffener (e.g., wax) during machining (for small quantities).

5. What quality certifications should a CNC micro machining provider have?

Look for ISO 9001 (general quality management) and ISO 13485 (for medical devices)—these ensure the provider follows strict quality control processes. For aerospace parts, AS9100 certification is critical. At Yigu Technology, we hold all three certifications to serve clients in regulated industries.