If you’ve ever wondered about high-precision 3D printing methods, SLA (Stereolithography) is likely one of the top technologies to explore. As one of the earliest 3D printing technologies invented, SLA has become a go-to choice for industries that demand detailed, smooth, and accurate 3D-printed parts—from jewelry design to medical device prototyping. In this guide, we’ll break down everything you need to know about SLA 3D printing, including how it works, its pros and cons, how it compares to other technologies like DLP, and when to choose it for your projects.

What Exactly Is SLA 3D Printing? and How Does It Compare to Other Resin Technologies?

SLA (Stereolithography) is a form of additive manufacturing (3D printing) that uses ultraviolet (UV) lasers to cure liquid photopolymer resin into solid, three-dimensional objects. It was developed in the 1980s by Chuck Hull, who is often called the “father of 3D printing,” and it remains one of the most widely used technologies for creating high-quality prototypes and end-use parts today.

Unlike some 3D printing methods that use plastic filaments (like FDM) or metal powders (like SLM), SLA relies on liquid resin. The UV laser “draws” each layer of the object on the resin’s surface, hardening the resin where the laser touches it. Once a layer is complete, the build platform moves down slightly, and the process repeats—layer by layer—until the entire object is finished.

SLA is a type of vat photopolymerization—a process that uses light to cure liquid resin into solid 3D objects. It’s one of three main resin-based 3D printing methods, but it stands out for its laser-driven precision. Let’s clarify how it differs from its counterparts:

| Technology | Light Source | Curing Method | Key Strengths | Best For |

| SLA (Stereolithography) | High-precision UV laser | Selectively cures resin layer-by-layer (laser traces cross-sections) | Ultra-fine details, smooth surfaces, high accuracy | Prototypes, dental models, small functional parts |

| DLP (Digital Light Processing) | Digital projector (UV light) | Flashes entire layers of light onto resin at once | Faster print speeds | Batch production of small parts (e.g., jewelry) |

| LCD (Liquid Crystal Display) | LCD screen (blocks/lets through light) | Projects light patterns to cure layers | Low cost, good detail for hobbyists | Desktop prototyping, consumer goods |

Real-World Example: Jewelry Prototyping

A small jewelry studio in New York uses SLA 3D printing to create detailed wax-like prototypes of rings and necklaces. Before SLA, the studio spent 4–6 hours carving each prototype by hand. With an SLA printer, they now produce a prototype in just 1.5 hours, with finer details (like tiny engravings) that were nearly impossible to achieve manually. This not only saves time but also helps them test more designs with clients before moving to metal casting.

How Does SLA 3D Printing Work? Step-by-Step Principle

Understanding the basic principle of SLA is key to knowing why it’s so good at creating precise parts. Here’s a simple breakdown of the process:

- Prepare the Resin Tank: The SLA printer’s tank is filled with liquid photopolymer resin, which is sensitive to UV light.

- First Layer Curing: The build platform lowers until it touches the surface of the resin (or is just a tiny distance above it). A UV laser then scans the surface of the resin, tracing the shape of the object’s first layer. Wherever the laser hits, the resin cures (hardens) into a solid.

- Layer-by-Layer Building: After the first layer is cured, the build platform descends by a small distance (equal to the thickness of one layer, usually 0.02–0.1mm). This allows fresh liquid resin to flow over the cured layer.

- Repeat Until Completion: The laser scans the next layer, and the process repeats. Over time, the layers stack up to form the full 3D object.

- Post-Processing: Once printing is done, the object is removed from the resin tank. It’s then rinsed with isopropyl alcohol (IPA) to remove excess resin and cured again under a UV lamp to strengthen the part.

A key difference between SLA and other methods (like FDM, which uses melted plastic filaments) is that SLA resins are thermoset polymers—once cured, they can’t be melted or reused. If you heat an SLA part too much (e.g., above 58°C for post-cured parts), it will burn, not soften.

Key Advantages of SLA 3D Printing

SLA’s popularity comes from its unique strengths, especially when it comes to quality and detail. Here are the top benefits:

- High Accuracy and Resolution: SLA can achieve layer heights as small as 0.01mm, resulting in parts with smooth surfaces and fine details (like thin walls or tiny holes). This makes it ideal for parts where precision matters, such as dental models or small mechanical components.

- Smooth Surface Finish: Unlike FDM (Fused Deposition Modeling), which leaves visible layer lines, SLA parts have a nearly seamless surface. This reduces the need for post-processing (like sanding) in many cases.

- Wide Range of Resins: SLA resins come in various types—flexible, rigid, transparent, or even biocompatible (for medical use). For example, a dental lab might use a biocompatible resin to print temporary crowns.

SLA’s biggest advantage? It produces parts with isotropic strength (uniform strength in all directions) and watertight seals—critical for applications like fluid flow components or medical devices. For example, NOAA (National Oceanic and Atmospheric Administration) uses SLA to print waterproof enclosures for underwater research tools, as the technology ensures no leaks even in high-pressure environments.

SLA Disadvantages: What to Watch Out For

While SLA is powerful, it has limitations to consider:

- Brittleness: Most SLA parts are brittle (like glass) compared to FDM’s flexible thermoplastics. Avoid using SLA for parts that need to bend (e.g., phone cases that absorb drops)—opt for tough resin instead.

- UV Sensitivity: SLA parts degrade over time in direct sunlight (they become brittle and discolor). Fix this by applying a UV-protective spray (e.g., clear acrylic spray) for outdoor use.

- Support Removal: Supports must be manually removed, which can leave marks. For visible parts (e.g., consumer product prototypes), sand the marks with fine-grit sandpaper.

- Resin Handling: Liquid resin is messy and can be toxic (some require gloves and ventilation). Always follow the manufacturer’s safety guidelines—for example, never pour uncured resin down the drain.

Key SLA Print Parameters: What Affects Quality, Speed, and Cost?

To get the best results from SLA, you need to optimize three core parameters: layer height, build size, and print orientation. These directly impact detail, print time, and part strength.

Layer Height: Detail vs. Speed

Layer height (the thickness of each cured layer) ranges from 25 to 150 microns. Thinner layers capture curved shapes (like a lens or dental implant) more accurately but increase print time and cost.

| Layer Height | Use Case | Print Time (Example: 5cm Cube) | Surface Finish |

| 25 microns | High-detail parts (e.g., microfluidic chips) | ~8 hours | Near-polished (no visible layer lines) |

| 50 microns | Prototypes (e.g., consumer electronics casings) | ~4 hours | Smooth (minimal layer lines) |

| 100 microns | Functional parts (e.g., jigs/fixtures) | ~2 hours | Good (slight layer lines, easy to sand) |

Real-World Tip: A 100-micron layer height works for 80% of SLA projects. For example, automotive designers at Rivian use 100-micron layers to print dashboard prototypes—fast enough for daily iterations, yet smooth enough to test fit and aesthetics.

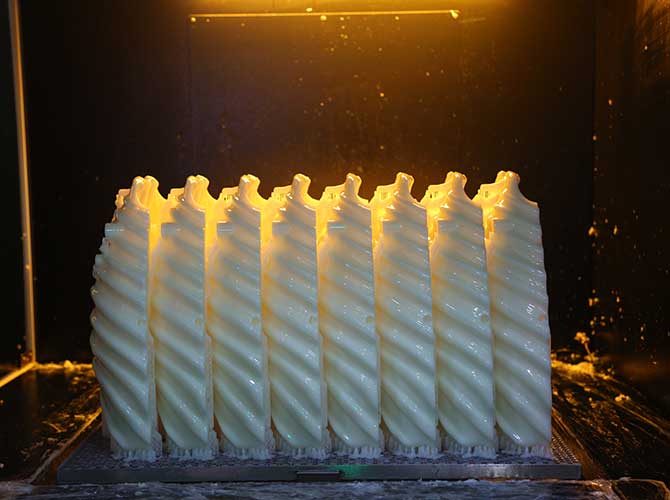

Build Size: Desktop vs. Industrial Systems

Build size depends on whether you use a bottom-up (desktop) or top-down (industrial) SLA printer. Bottom-up printers are smaller and cheaper, while top-down systems handle large parts.

| Printer Type | Build Size Range | Key Limitation | Example Use Case |

| Bottom-Up (Desktop, e.g., Formlabs Form 4) | Up to 145 x 145 x 175 mm | Peeling forces can cause failures for large parts | Dental models, small prototypes |

| Top-Down (Industrial, e.g., 3D Systems ProX 950) | Up to 1500 x 750 x 500 mm | Higher cost, needs specialist operators | Aerospace components (e.g., drone wings) |

Case Study: Unilever uses industrial SLA printers to print large molds for blow-molded bottles. A 3D-printed mold (1000 x 500 mm) takes 2 weeks to produce—compared to 6–8 weeks for a machined metal mold—and costs \(500–\)1,000 vs. \(2,500–\)10,000.

Print Orientation: Minimizing Supports and Curling

Orientation affects two big issues: support structures (needed to hold overhangs) and curling (resin shrinkage that warps parts).

- Top-Down Printers: Supports work like FDM—minimize them by printing flat. Critical overhang angle: ~30° (any overhang steeper than this needs support).

- Bottom-Up Printers: Require more complex supports to resist peeling forces. Orient parts at an angle (e.g., 45°) to reduce cross-sectional area and prevent detachment.

How to Fix Curling:

- Add extra supports to vulnerable areas (e.g., thin walls).

- Avoid large flat surfaces (split them into smaller sections).

- Don’t over-cure (e.g., keep parts out of direct sunlight post-printing).

SLA Materials: Choosing the Right Resin for Your Project

SLA resins are tailored to specific needs—from flexible rubber-like parts to high-temperature-resistant components. Below are the most common types, with real-world examples:

| Resin Type | Key Properties | Applications | Example |

| Standard Resin | Smooth surface, low cost, brittle | Visual prototypes (e.g., toy models) | A product designer prints a phone case prototype to test grip and aesthetics. |

| Dental Resin | Biocompatible, high accuracy | Crown models, surgical guides | A dentist uses Precision Model Resin (Formlabs) to print a crown model with >99% surface accuracy. |

| Tough/Durable Resin | ABS-like strength, impact-resistant | Functional parts (e.g., connectors) | Battle Beaver Customs prints gaming controller components with Tough Resin—they withstand 10,000+ button presses. |

| High-Temperature Resin | Withstands up to 200°C | Mold inserts, aerospace parts | An engineer prints a mold insert for injection molding using High Temp Resin (Accura 5530)—it resists heat from molten plastic. |

| Clear Resin | Transparent, polishable to optical clarity | Lenses, fluid flow models | OXO uses Clear Resin to print coffee maker prototypes—they test how water flows through the machine without disassembling it. |

Pro Tip: Industrial SLA systems offer more material options than desktop printers. For example, 3D Systems’ ProX printers work with ceramic-filled resins (for heat-resistant parts), while desktop printers (like Form 4) focus on general-purpose and dental resins.

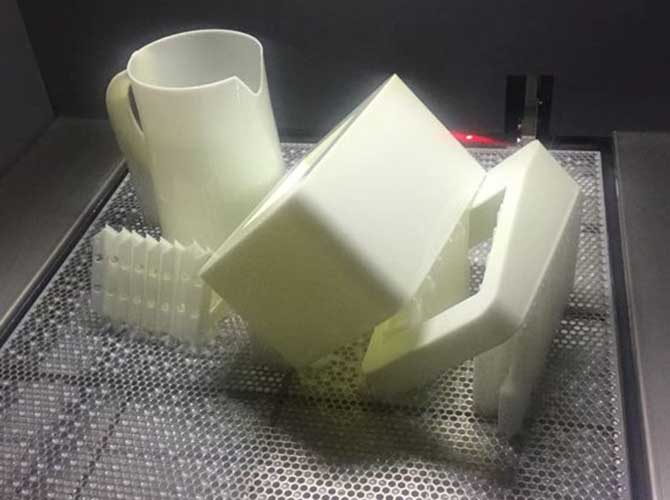

SLA Post-Processing: From “Green Part” to Finished Product

Post-processing is non-negotiable for SLA—it turns a sticky, partially cured “green part” into a strong, usable object. Here’s the typical workflow, using a clear resin lens as an example:

- Wash the Part: Soak the lens in IPA (90% concentration) for 5–10 minutes to remove uncured resin. Use a ultrasonic cleaner (like Formlabs Form Wash) for hard-to-reach areas (e.g., small holes in the lens).

- Dry Thoroughly: Air-dry for 30 minutes or use a hair dryer (low heat) to speed up drying. Residue IPA can cause cloudiness in clear parts.

- Post-Cure: Place the lens in a UV curing chamber (e.g., Formlabs Form Cure) for 10–30 minutes. This boosts tensile strength (from 38 MPa to 65 MPa) and heat resistance (from 42°C to 58°C).

- Finish (Optional): Sand the lens with 400–2000 grit sandpaper, then polish with a microfiber cloth and plastic polish. This removes support marks and makes the lens nearly as clear as glass.

Common Mistake to Avoid: Skipping post-cure. A dental surgical guide that’s not post-cured may crack during use—post-curing ensures it retains its shape under pressure.

Desktop vs. Industrial SLA 3D Printers: Which Should You Choose?

The decision between desktop and industrial SLA depends on your project’s size, volume, and precision needs. Let’s compare them side-by-side:

| Factor | Desktop SLA (e.g., Formlabs Form 4) | Industrial SLA (e.g., 3D Systems ProX 950) |

| Cost | \(3,000–\)10,000 (printer) + \(50–\)200/resin tank | \(50,000–\)500,000 (printer) + \(500–\)2,000/resin tank |

| Accuracy | ±0.5% (lower limit: ±0.10 mm) | ±0.15% (lower limit: ±0.01 mm) |

| Build Size | Up to 145 x 145 x 175 mm | Up to 1500 x 750 x 500 mm |

| Material Range | Standard, tough, dental resins | High-temp, ceramic, biocompatible resins |

| Best For | Small-batch prototyping (e.g., startup product tests) | Large parts, high-volume production (e.g., aerospace components) |

Real-World Example: A small dental lab uses a Formlabs Form 4B (desktop) to print 10–20 crown models per day. A large aerospace company like Boeing uses industrial SLA to print 1-meter-long turbine components for jet engines—needing the larger build size and high-temperature resins.

In-Depth Case Studies: How Industries Use SLA 3D Printing

Let’s explore how three industries—dental, aerospace, and consumer goods—leverage SLA to solve real problems.

Case Study 1: Dental Lab Cuts Production Time by 70% with SLA

Challenge: A small dental lab in Chicago was outsourcing crown model production—lead times were 5 days, and costs were $25 per model. They needed to speed up delivery and reduce costs.

Solution: They invested in a Formlabs Form 4B (desktop SLA printer) and dental-specific resins (Precision Model Resin and Surgical Guide Resin).

Results:

- Lead time dropped from 5 days to 1 day (they print models overnight).

- Cost per model fell from $25 to $8 (resin + labor).

- Accuracy improved: 99% of models match the patient’s scan (vs. 90% from outsourcing).

Quote from the Lab Manager: “We now can print a crown model while the patient is still in the chair—they leave with a temporary crown the same day. It’s transformed our customer experience.”

Case Study 2: Aerospace Company Prints High-Temp Components with Industrial SLA

Challenge: Boeing needed to print small turbine components for jet engines—parts needed to withstand 180°C and have tight tolerances (±0.01mm). Traditional machining was slow and expensive.

Solution: They used a 3D Systems ProX 950 (industrial SLA printer) and high-temp resin (Accura 5530).

Results:

- Production time for 10 components dropped from 2 weeks to 3 days.

- Cost per component fell from $500 to $200 (no tooling needed).

- Parts passed all tests: they withstood 180°C for 1000 hours without deforming.

Key Insight: Industrial SLA is now viable for end-use aerospace parts—previously, it was only used for prototypes.

Case Study 3: Consumer Goods Brand Tests New Designs Fast with SLA

Challenge: OXO (maker of kitchen tools) wanted to test 10 different designs for a new garlic press—they needed prototypes that looked and felt like the final product (smooth, durable, and watertight).

Solution: They used a Formlabs Form 3L (large-format SLA printer) and Clear Resin (for watertightness) and Tough Resin (for durability).

Results:

- Prototypes were printed in 2 days (vs. 2 weeks for FDM).

- They tested all 10 designs in 1 month (vs. 3 months with outsourcing).

- The final design had 40% better user satisfaction (thanks to SLA’s smooth surface, which made the press easier to clean).

Lesson Learned: SLA’s surface finish isn’t just aesthetic—it impacts how users interact with the product.

SLA vs. DLP: A Detailed Comparison

While SLA is great for precision, it’s not the only resin-based 3D printing technology. DLP (Digital Light Processing) is another popular option, and knowing their differences helps you choose the right one. Below is a side-by-side comparison:

| Feature | SLA (Stereolithography) | DLP (Digital Light Processing) |

| Curing Method | Uses a single UV laser to scan and cure layer by layer | Uses a UV projector to cure an entire layer at once |

| Speed | Slower (since the laser scans each point) | Faster (cures full layers in seconds) |

| Accuracy | Higher (laser spot size as small as 0.05mm) | Lower (affected by projector resolution; larger parts have lower detail) |

| Print Size Limitations | Larger build volumes possible (some printers handle 300mm+ parts) | Smaller build volumes (projector resolution drops with larger areas) |

| Cost | Higher upfront cost (laser components are expensive) | Lower upfront cost (projectors are more affordable) |

| Best For | High-detail parts (jewelry, dental models, prototypes) | Fast prototyping, low-detail parts (toys, basic models) |

Real-World Example: Medical Device Prototyping

A medical device company needs to print two types of parts: 1) small, detailed surgical guides (with tiny holes for screws) and 2) large, basic housing for a diagnostic tool. For the surgical guides, they use SLA—its high accuracy ensures the holes align perfectly with patient anatomy. For the housing, they use DLP—since speed is more important than fine detail, DLP cuts the printing time from 8 hours (SLA) to 3 hours.

When Should You Choose SLA 3D Printing?

SLA is not the best fit for every project, but it shines in specific scenarios. Here are the top use cases where SLA is the ideal choice:

- Projects Requiring Fine Details: If your part has small features (like engravings, thin walls, or intricate patterns), SLA’s high resolution will deliver better results than DLP or FDM. For example, a watchmaker using SLA to print tiny gear prototypes.

- Smooth Surface Finish Needs: When you want parts that look professional without heavy post-processing (like sanding or painting), SLA’s seamless layers are a big advantage. This is common in consumer products like phone cases or toy prototypes.

- Biocompatible or Specialized Parts: SLA resins include biocompatible options, making it suitable for medical applications (e.g., custom hearing aids, surgical templates) or industrial parts that need heat resistance (e.g., small engine components).

Top SLA 3D Printing Tips for Success

- Optimize Part Orientation: For a dental crown, orient the top (visible) surface upward to minimize support marks—this saves polishing time.

- Use the Right Layer Height: For functional parts (e.g., jigs), 100 microns balances speed and strength. For display models, 25–50 microns ensures smoothness.

- Post-Cure Properly: Under-cured parts are weak—use a timer to ensure you hit the recommended cure time (e.g., 20 minutes for Formlabs Clear Resin).

- Store Resin Correctly: Keep resin in a cool, dark place (away from sunlight) to prevent premature curing. Most resins have a 6-month shelf life.

- Test with Small Parts First: Before printing a large part (e.g., a 30cm aerospace component), print a 5cm test piece to check for curling or support issues—this saves resin and time.

Final Thoughts: Is SLA 3D Printing Right for You?

SLA is ideal if you need:

- High-precision parts (e.g., dental models, microfluidics).

- Smooth surface finishes (e.g., consumer product prototypes).

- Watertight or isotropic parts (e.g., medical devices, underwater tools).

It’s less ideal if you need:

- Large, flexible parts (e.g., toys, wearable tech)—choose FDM.

- Low-cost, high-volume production (e.g., 10,000+ parts)—choose injection molding.

Whether you’re a startup designer, a dental lab technician, or an aerospace engineer, SLA’s versatility and precision make it a valuable tool. With the right printer, resin, and post-processing, you can turn digital designs into high-quality physical parts in hours—not days.

Yigu Technology’s View on SLA 3D Printing

At Yigu Technology, we believe SLA remains a cornerstone of high-precision 3D printing for industries that prioritize quality and detail. Over the years, we’ve supported clients in jewelry, dental, and aerospace fields by integrating SLA technology into their workflows—helping them cut prototyping time by 30–50% while improving part accuracy. While DLP is better for speed, SLA’s ability to produce consistent, detailed parts makes it irreplaceable for projects where precision can’t be compromised. We also recommend SLA for clients new to resin 3D printing, as its mature ecosystem (resins, post-processing tools) makes it easy to adopt and scale.

FAQ:

Q1: Is SLA 3D printing expensive?

SLA printers typically cost more upfront than DLP or FDM printers (starting around \(2,000 for entry-level models, vs. \)500 for basic FDM). However, for projects needing high detail, the cost is often justified—you’ll save money on post-processing and reduce design iterations. Resin costs also vary: basic resins are \(50–\)100 per liter, while specialized resins (biocompatible) can be $200+ per liter.

Q2: How long does it take to print a part with SLA?

Print time depends on the part’s size, layer height, and complexity. A small part (e.g., a 20mm jewelry prototype) might take 1–2 hours, while a larger part (e.g., a 150mm toy model) could take 6–10 hours. Remember: SLA is slower than DLP, but faster than some high-precision FDM printers.

Q3: Are SLA parts strong enough for end-use?

Yes—depending on the resin. Rigid SLA resins can be as strong as some plastics (like ABS), making them suitable for end-use parts like small gears or phone cases. However, SLA parts are not as strong as metal parts or high-performance FDM parts (like those made with nylon). For load-bearing parts (e.g., machine components), you may need to use a reinforced resin or consider other technologies.

Q4: Why Did My SLA Print Fail (and How to Fix It)?

Print failures are common, but most stem from three issues: resin issues, support problems, or curing inconsistencies.

| Failure Type | Common Cause | Solution |

|---|---|---|

| Layer Separation | Resin is too old (expired) or not mixed well | Use fresh resin (check expiration date) and stir for 2–3 minutes before printing. |

| Part Sticks to Resin Tank (Bottom-Up Printers) | Tank’s flexible film is worn out or resin is too viscous | Replace the tank’s film (every 10–15 prints) or warm resin to 25°C (reduces viscosity). |

| Curling or Warping | Over-curing (too much UV light) or poor orientation | Reduce UV exposure time (e.g., from 8s to 6s per layer) or tilt the part to distribute stress. |

| Support Breakage | Supports are too thin or spaced too far apart | Increase support thickness (from 0.2mm to 0.4mm) and reduce spacing (from 5mm to 3mm). |

Example: A product designer was printing a thin-walled phone case that kept curling. By tilting the case 30° (to avoid large flat surfaces) and reducing UV exposure time by 2 seconds per layer, the next print came out perfectly flat.

Q5: How Much Does SLA 3D Printing Cost?

Cost depends on three factors: printer type, resin, and post-processing. Here’s a breakdown for a small prototype (5cm x 5cm x 5cm):

| Cost Category | Desktop SLA (Formlabs Form 4) | Industrial SLA (3D Systems ProX) |

|---|---|---|

| Printer (Upfront) | $3,500–$5,000 | $50,000–$200,000 |

| Resin (Per Print) | $5–$10 (uses ~10–20ml of standard resin) | $20–$50 (uses ~20–40ml of high-temp resin) |

| Post-Processing (Wash/Cure) | $1–$2 (IPA and electricity) | $5–$10 (specialized cleaning solutions) |

| Labor | $10–$15 (30 mins of work) | $20–$30 (1 hour of specialist time) |

| Total Per Print | $17–$28 | $45–$90 |

Note: For large batches (e.g., 100 dental models), desktop SLA becomes more cost-effective—total cost per model drops to $8–$12 (vs. $15–$20 for outsourcing).

Q6: Can SLA Parts Be Painted or Plated?

Yes! SLA parts take paint and plating well, thanks to their smooth surface. Here’s how to do it:

- Painting: Sand the part with 400-grit sandpaper, apply a primer (e.g., acrylic primer), then use spray paint or acrylic paint. For a glossy finish, add a clear coat.

- Metal Plating: Use a ceramic-filled resin (e.g., Somos PerFORM) for the part, then plate it with nickel or chrome. This is common for decorative parts (e.g., jewelry) or functional components (e.g., electrical connectors).

Case: A jewelry designer prints rings with castable resin, then plates them with 24k gold—customers can’t tell the difference between 3D-printed and traditionally cast rings.