If you’re a manufacturer in France looking to produce high-quality, low-volume plastic or rubber parts with precise details, vacuum casting is likely your top choice. Simply put, vacuum casting in France is a rapid prototyping and low-volume production process that uses a silicone mold to create replicas of a master pattern—all under vacuum to eliminate air bubbles and ensure smooth, accurate parts. It’s ideal for businesses needing 10 to 1000 units, bridging the gap between 3D printing (too small-scale) and injection molding (too costly for low volumes). Whether you’re in automotive, medical, or consumer goods, this guide will answer every question you have about leveraging vacuum casting in the French market.

What Is Vacuum Casting, and Why Is It Popular in France?

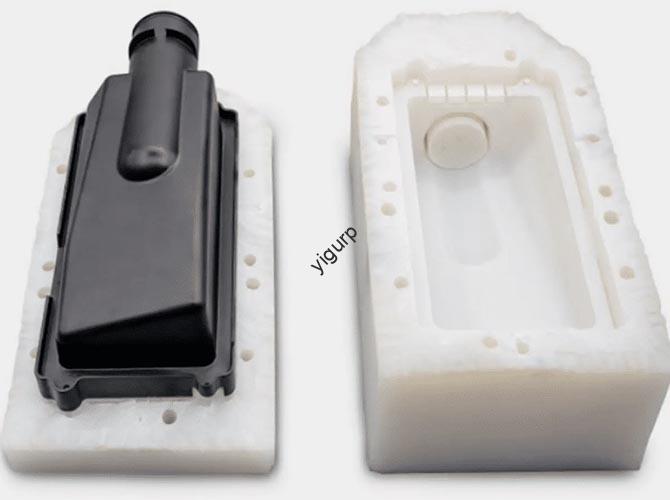

Before diving into local specifics, let’s clarify the basics. Vacuum casting (also called urethane casting) works by first creating a master model—usually via 3D printing (SLA or SLS) or CNC machining. A silicone mold is then poured over this master and cured. Once the mold is ready, liquid polyurethane resin (or rubber) is poured into it under vacuum pressure. The vacuum removes air pockets, ensuring the resin fills every detail of the mold. After curing, the mold is opened, and the part is removed.

In France, vacuum casting has gained massive popularity for three key reasons. First, the country’s strong focus on precision manufacturing—especially in sectors like aerospace (Toulouse), medical devices (Lyon), and luxury goods (Paris)—demands parts with tight tolerances (often ±0.1mm) and high surface quality, which vacuum casting delivers. Second, French regulations (such as REACH for chemicals and CE for medical devices) are strict, and local vacuum casting providers specialize in compliant materials, saving businesses time on certification. Third, the speed: unlike injection molding, which can take 4–8 weeks for tooling, vacuum casting molds are ready in 3–7 days, with parts produced in 1–2 days—critical for French companies competing in fast-paced markets.

A real-world example: A Paris-based startup developing a new wearable medical device needed 50 prototype parts to test on patients. They used a local vacuum casting service to create parts from biocompatible polyurethane (compliant with ISO 10993). The process took just 10 days total—from master model to finished parts—allowing them to start clinical trials 6 weeks faster than if they’d used injection molding.

Key Applications of Vacuum Casting in French Industries

Vacuum casting isn’t a one-size-fits-all solution—it’s tailored to the unique needs of France’s top manufacturing sectors. Below are the most common uses, with specific examples to illustrate its value:

1. Automotive and Aerospace

France’s automotive (e.g., Renault, Peugeot) and aerospace (Airbus) industries rely on vacuum casting for functional prototypes and low-volume custom parts. For instance, an aerospace supplier in Bordeaux used vacuum casting to produce 200 lightweight, heat-resistant sensor housings. The process allowed them to test different resin formulations (including flame-retardant options) without investing in expensive metal tooling. In automotive, vacuum casting is often used for interior components like dashboard prototypes or custom trim pieces—helping designers validate fit and finish before mass production.

2. Medical Devices

Compliance is non-negotiable in medical manufacturing, and French vacuum casting providers excel here. A Lyon-based medical device company used vacuum casting to create 150 prototypes of a new insulin pen housing. They chose a USP Class VI-certified resin, which meets strict biocompatibility standards. The parts were produced with a smooth, easy-to-clean surface (critical for medical use) and included precise features like threaded ports for needles. The service also provided material certification documents, simplifying the company’s CE marking process.

3. Luxury Goods and Consumer Products

Paris is a global hub for luxury goods, and vacuum casting helps brands like Louis Vuitton or Cartier create high-end prototypes and limited-edition parts. For example, a luxury watchmaker used vacuum casting to produce 50 prototype watch cases in a polyurethane resin that mimicked the look and feel of stainless steel. The process allowed them to test different finishes (matte, polished) and intricate details (engravings) without the cost of metal tooling. In consumer goods, vacuum casting is used for items like custom phone cases, household appliance parts, or toy prototypes—ideal for small-batch runs or market testing.

How to Choose a Vacuum Casting Service in France: A Practical Checklist

Not all vacuum casting providers in France are the same. To ensure you get quality parts, on-time delivery, and compliance, use this checklist:

| Factor to Evaluate | What to Look For | Why It Matters |

| Material Selection | Offers a wide range of resins (polyurethane, rubber, ABS-like, biocompatible) and provides material data sheets (MDS) for compliance. | The right material determines part strength, flexibility, and compliance with French regulations (REACH, CE). |

| Tolerance Capabilities | Can consistently produce parts with tolerances of ±0.1mm to ±0.2mm (depending on part size). | Precision is critical for functional parts (e.g., medical devices, aerospace components). |

| Lead Times | Guarantees mold production in 3–7 days and parts in 1–2 days (for standard orders). | Fast turnaround helps you meet project deadlines (e.g., clinical trials, trade shows). |

| Quality Control | Has a documented QC process (e.g., dimensional testing with calipers or 3D scanners) and offers sample parts before full production. | Prevents costly mistakes and ensures parts meet your specifications. |

| Compliance Expertise | Specializes in your industry’s regulations (e.g., ISO 13485 for medical, ISO 9001 for general manufacturing) and provides certification documents. | Avoids delays in product launch due to non-compliant parts. |

| Customer Reviews | Has positive feedback from French clients (check platforms like Trustpilot or industry forums). | Local experience means they understand French market needs and logistics. |

Pro Tip: Ask for a sample. A reputable provider will produce a small test part (often at a reduced cost) so you can inspect quality before placing a full order. For example, a Marseille-based electronics company requested a sample of a custom connector housing—this allowed them to test the part’s fit with other components and confirm the resin’s durability before ordering 500 units.

Cost Breakdown: Vacuum Casting in France vs. Other Methods

Cost is a key consideration for manufacturers, so let’s compare vacuum casting to two common alternatives: 3D printing (SLA) and injection molding. The numbers below are based on average French market rates for a small part (10cm x 5cm x 2cm):

| Production Method | Tooling Cost | Unit Cost (for 100 parts) | Total Cost (100 parts) | Lead Time | Best For |

| Vacuum Casting | €300–€800 (silicone mold) | €5–€15 | €800–€2300 | 1–2 weeks | Low-volume production (10–1000 units), high-quality parts. |

| 3D Printing (SLA) | €0 (no tooling) | €20–€40 | €2000–€4000 | 3–5 days | Very small batches (1–10 parts), rapid prototyping. |

| Injection Molding | €5,000–€15,000 (metal mold) | €0.50–€2 | €5,500–€17,000 | 4–8 weeks | High-volume production (10,000+ units). |

As you can see, vacuum casting is the most cost-effective option for French manufacturers needing 10 to 1000 parts. For example, a Nantes-based toy company needed 500 custom toy figures. Vacuum casting cost them ~€1,500 total—compared to €2,000 for 3D printing or €6,000 for injection molding. It also allowed them to use a flexible resin that made the toys safer for children, which 3D printing couldn’t match at that price point.

Common Challenges in Vacuum Casting (and How French Providers Solve Them)

Even with a great process, challenges can arise. Here are the most common issues and how local French services address them:

1. Air Bubbles in Parts

Air bubbles ruin surface quality and structural integrity. French providers solve this by using dual-stage vacuum systems: first, they degas the liquid resin before pouring it into the mold, then they place the mold in a vacuum chamber during casting. A Strasbourg-based provider, for example, uses a vacuum pressure of -95 kPa to ensure all air is removed. They also inspect each part with a magnifying glass (10x) to catch any tiny bubbles before shipping.

2. Mold Degradation

Silicone molds have a limited lifespan (usually 10–25 uses, depending on resin type). To avoid unexpected mold failure, French services track mold usage and notify you when a new mold is needed. They also use high-quality silicone (e.g., Shore A 40–60 hardness) that resists wear from harsh resins (like those with fillers). For a Lille-based automotive supplier needing 200 parts, the provider replaced the mold after 22 uses—ensuring the last part was just as precise as the first.

3. Material Compatibility Issues

Using the wrong resin can lead to parts that crack, warp, or fail compliance tests. French providers have in-house material experts who help you choose the right option. For example, a Toulouse-based aerospace company initially chose a rigid resin for a sensor housing, but the expert recommended a more flexible resin that could withstand temperature changes (-40°C to 80°C) in aircraft. This saved the company from reworking 100 parts and delayed deadlines.

Yigu Technology’s Perspective on Vacuum Casting in France

At Yigu Technology, we recognize that France’s vacuum casting market stands out for its emphasis on precision, compliance, and industry-specific expertise—especially in medical and aerospace sectors. What sets French services apart is their ability to balance speed with regulatory rigor; they don’t just produce parts—they provide the documentation and support needed to meet strict EU standards. For manufacturers, this means less time navigating red tape and more time innovating. We also see a growing trend in France toward sustainable vacuum casting: many local providers now offer eco-friendly resins (e.g., bio-based polyurethanes) and recycling programs for old molds. This aligns with global sustainability goals and helps French businesses reduce their carbon footprint. For companies looking to enter the French market, partnering with a local vacuum casting service isn’t just a practical choice—it’s a strategic one to ensure quality and compliance from day one.

FAQ About Vacuum Casting in France

1. How long does vacuum casting take in France?

Most French providers complete mold production in 3–7 days and part production in 1–2 days. For urgent orders (e.g., last-minute prototype needs), some offer expedited services (2–3 days for molds, 24 hours for parts) for an additional fee.

2. Can vacuum casting parts be painted or finished?

Yes! French services offer post-processing options like painting (spray or hand-painted), sanding, polishing, or adding textures (e.g., matte, glossy). For luxury goods, some even provide metal plating (e.g., chrome, gold) to mimic high-end materials.

3. Are vacuum casting parts in France compliant with EU regulations?

Absolutely—reputable providers use resins that meet REACH (chemical safety), CE (product safety), and industry-specific standards (e.g., ISO 13485 for medical, ISO 14001 for sustainability). They also provide certification documents to prove compliance.

4. What’s the maximum part size for vacuum casting in France?

Most providers can handle parts up to 50cm x 50cm x 30cm. For larger parts (e.g., automotive bumpers), some offer split molds (multiple silicone pieces that fit together) to cast larger components.

5. How do I send my design to a French vacuum casting service?

Providers accept 3D CAD files (e.g., STL, STEP, IGES) via email or cloud platforms (e.g., Dropbox, WeTransfer). Many also offer design reviews—they’ll check your CAD file for issues (e.g., thin walls that might crack) and suggest improvements before creating the master model.