If you’ve ever worked with titanium, you know it’s not like turning aluminum or steel. This high-performance metal brings unique benefits—like incredible strength at high temperatures and corrosion resistance—but it also throws tough challenges your way. Whether you’re machining aerospace components or medical implants, getting turning right is critical to quality, efficiency, and tool life. In this guide, we’ll break down everything you need to know: from understanding titanium’s tricky properties to choosing the best tools, setting optimal parameters, and optimizing your process. By the end, you’ll feel confident tackling even the most complex titanium turning jobs.

1. Understanding Titanium: Key Material Properties and Common Challenges

Before you start turning, it’s essential to grasp why titanium behaves the way it does. Its unique properties are what make it valuable for industries like aerospace and medicine—but they also make machining a battle. Let’s break down the critical characteristics and the challenges they create, with real-world examples to illustrate.

The Properties That Define Titanium Turning

- High Strength at Temperature: Unlike many metals, titanium retains its strength even at temperatures above 600°F (315°C). This is a huge plus for parts like jet engine components, but it means the metal doesn’t soften during cutting—putting more stress on your tools.

- Low Thermal Conductivity: Titanium conducts heat 1/16th as well as aluminum. When you cut it, most heat stays in the chip and at the cutting edge (not the workpiece), which can quickly wear out tools or cause thermal damage.

- Work Hardening: Titanium hardens rapidly when deformed. If your tool rubs against the workpiece (instead of cutting cleanly), the surface hardens, making subsequent cuts even harder—leading to tool chipping or breakage.

- Chemical Reactivity: At high temperatures, titanium reacts with oxygen, nitrogen, and carbon. This can form a brittle layer on the workpiece surface (called “alpha case”) or bond with the tool material, causing galling.

- Notch Sensitivity: Titanium is prone to cracking if there are sharp notches or stress concentrations. This is a big risk when turning parts with grooves or thin walls, as even small tool marks can lead to failure.

Real-World Challenge Example

Aerospace shops often machine Ti-6Al-4V (the most common tough titanium alloy) for aircraft brackets. One shop I worked with was struggling with frequent tool failures: their carbide inserts were chipping after just 20 minutes of turning. After investigating, we found two issues: 1) Their feed rate was too low, causing the tool to rub (instead of cut) and trigger work hardening. 2) They weren’t using enough coolant, so heat built up at the cutting edge. By adjusting the feed rate and switching to high-pressure coolant, they extended tool life to 90 minutes—a 350% improvement.

Common Turning Challenges (and Quick Fixes)

| Challenge | Root Cause | Immediate Fix |

| Galling | Tool-workpiece bonding due to heat | Use a sharp cutting edge + specialized coating |

| Poor Chip Control | Low thermal conductivity (chip sticks) | Add a chip breaker + optimize feed rate |

| Heat Generation | Low thermal conductivity | High-pressure coolant + reduced cutting speed |

| Work Hardening | Tool rubbing (not cutting cleanly) | Increase feed rate + use positive rake angle |

2. Choosing the Right Cutting Tools for Titanium Turning

The wrong tool can turn a simple titanium job into a nightmare. Unlike steel, titanium requires tools that can handle high heat, resist wear, and avoid bonding with the metal. Let’s break down the best tool materials, geometries, and coatings—with comparisons to help you decide.

Tool Material Options: Which Is Best?

Not all tool materials are equal for titanium. Here’s a detailed comparison of the most common choices:

| Tool Material | Best For | Strengths | Limitations | Recommended Alloys |

| Uncoated Carbide | General-purpose Ti turning | Affordable, good toughness | Wears fast at high temps | Ti-6Al-4V (low-volume) |

| Coated Carbide | High-volume Ti production | Resists heat/wear (coating acts as barrier) | Coating can chip if feed rate is too high | Ti-6Al-4V, Ti-5Al-2.5Sn |

| PCD (Polycrystalline Diamond) | Non-reactive Ti alloys (no iron) | Extremely hard, low friction | Reacts with titanium containing iron | Pure titanium (CP Ti) |

| CBN (Cubic Boron Nitride) | Hardened Ti alloys | Handles high temps, resists bonding | Expensive (best for precision jobs) | Ti-10V-2Fe-3Al |

Critical Tool Geometry Features

Even the best material won’t perform well if the tool geometry is wrong. For titanium, focus on these:

- Positive Rake Angle: A positive angle (5°–15°) reduces cutting force and minimizes work hardening. Avoid negative rake angles—they increase rubbing and heat.

- Sharp Cutting Edge: Dull edges cause rubbing (and work hardening). Keep edges sharp, but not too sharp (they’ll chip easily). A small edge radius (0.002″–0.004″) balances sharpness and strength.

- Rugged Tool Geometry: Thick tool shanks and strong insert seats reduce vibration. Titanium cutting creates high forces, so a flimsy tool will flex and cause poor surface finish.

- Chip Breaker: Essential for controlling chips. Look for chip breakers designed for titanium—they’ll break the long, stringy chips (common with Ti) into manageable pieces, preventing tangles.

Expert Tip: Coatings Matter

Specialized coatings can extend tool life by 50%–100% for titanium. The best options are:

- AlTiN (Aluminum Titanium Nitride): Resists high heat (up to 1,100°C/2,012°F) and reduces friction. Great for coated carbide tools.

- TiAlN (Titanium Aluminum Nitride): Similar to AlTiN but with better adhesion to carbide. Good for general titanium turning.

- Diamond-Like Carbon (DLC): Low friction, but only for low-temperature jobs (it degrades above 400°C/752°F). Avoid for high-speed turning.

3. Machining Parameters and Strategies: Get the Settings Right

Even with the best tools, bad parameters will ruin your titanium turning. The goal is to balance speed, feed, and depth of cut to minimize heat, avoid work hardening, and maximize tool life. Let’s walk through the key parameters and proven strategies—with real data to back it up.

Core Parameters to Optimize

The “big three” parameters for titanium turning are SFM (Surface Feet per Minute), Feed Rate, and Depth of Cut (DOC). Here’s what you need to know:

1. SFM (Cutting Speed)

- General Rule: Lower SFM than steel. For Ti-6Al-4V:

- Carbide tools: 30–60 SFM (slower for harder alloys like Ti-10V-2Fe-3Al).

- CBN tools: 80–120 SFM (for precision finishing).

- Why Slow Down? High SFM increases heat, which leads to tool wear and alpha case formation. A shop I consulted cut Ti-6Al-4V at 80 SFM with carbide tools—their inserts lasted 15 minutes. When they dropped to 45 SFM, tool life jumped to 60 minutes.

2. Feed Rate

- General Rule: Higher than you think. For Ti-6Al-4V with a 0.125″ insert:

- Roughing: 0.003″–0.005″ per revolution (IPR).

- Finishing: 0.001″–0.003″ per revolution.

- Why Higher Feed? A higher feed rate ensures the tool cuts (not rubs) the material, reducing work hardening. Just don’t go too high—excessive feed can cause tool chipping.

3. Depth of Cut (DOC)

- General Rule: Aggressive for roughing, light for finishing.

- Roughing: 0.100″–0.250″ (remove as much material as possible in one pass to minimize tool contact time).

- Finishing: 0.010″–0.030″ (light cuts reduce heat and improve surface finish).

Game-Changing Strategies

- Constant Feed: Avoid varying feed rates—this causes inconsistent cutting forces and work hardening. Use a CNC program that maintains a steady feed throughout the cut.

- High-Pressure Coolant (HPC): This is non-negotiable for titanium. HPC (1,000–3,000 psi) blasts coolant directly at the cutting edge, flushes chips away, and reduces heat. One study found HPC reduced tool wear by 40% compared to flood coolant.

- Rigid Setup: Titanium cutting creates high vibrations. Secure the workpiece with a heavy-duty chuck, use a short tool overhang (max 3x tool diameter), and tighten all clamps. A wobbly setup leads to poor surface finish and tool breakage.

- Vibration Avoidance: If you hear a “chattering” sound, stop immediately. Adjust the feed rate (increase by 10%) or SFM (decrease by 10%) to eliminate vibration.

4. Toolpath and Process Optimization: Boost Efficiency and Quality

Once you have the right tools and parameters, optimizing your toolpath and process will take your titanium turning to the next level. The goal is to minimize tool contact time, reduce air cutting, and manage heat—all while maintaining precision.

Key Toolpath Techniques for Titanium

- Climb Turning: Also called “downward turning,” this technique has the tool cut in the direction of the workpiece rotation. It reduces cutting forces, minimizes work hardening, and improves surface finish. For thin-wall titanium parts (common in aerospace), climb turning is a must—it prevents the workpiece from flexing.

- Trochoidal Turning: This is a game-changer for deep cuts or narrow spaces. Instead of feeding the tool straight into the material, it follows a circular (trochoidal) path. This reduces tool contact time, spreads heat, and prevents work hardening. I used trochoidal turning to machine a Ti-6Al-4V deep groove (0.5″ depth) and cut cycle time by 30%—with no tool chipping.

- Minimize Air Cutting: Air cutting (when the tool moves without cutting material) wastes time and can cause unnecessary vibration. Program your CNC to skip empty moves—for example, move directly from the end of one cut to the start of the next, instead of retracting fully.

- Avoid Dwell: Never let the tool sit in one spot on the titanium workpiece. Dwell causes heat to build up, leading to alpha case formation or tool bonding. If you need to pause, retract the tool slightly from the workpiece.

Process Monitoring and Maintenance

- Real-Time Process Monitoring: Use sensors (like force or temperature sensors) to track cutting conditions. If heat spikes or vibration increases, the system can adjust parameters automatically. One medical implant shop used this to reduce scrap rates from 15% to 3%.

- Predictive Maintenance: Don’t wait for tools to fail. Use data (like tool life for Ti-6Al-4V) to schedule tool changes before they wear out. For example, if your coated carbide inserts last 80 minutes on Ti-6Al-4V, change them at 70 minutes to avoid sudden failures.

- Thermal Management: Keep the workpiece and tool cool. In addition to HPC, consider using coolant with a high thermal conductivity (like synthetic coolants). Avoid mineral-based coolants—they can react with titanium at high temperatures.

5. Application-Specific Considerations: Tailor Your Approach

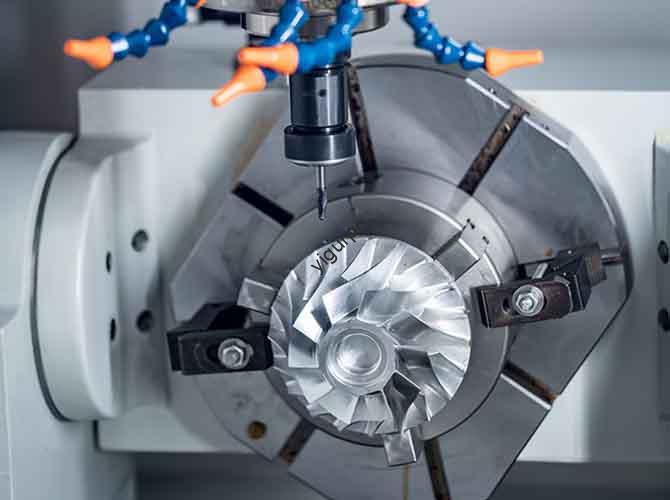

Titanium turning isn’t one-size-fits-all. The way you machine an aerospace turbine blade is very different from how you machine a medical hip implant. Let’s break down key applications and the unique considerations for each.

1. Aerospace Components

- Common Parts: Turbine blades, brackets, fasteners (often Ti-6Al-4V or Ti-5Al-2.5Sn).

- Key Challenges: Thin walls (prone to flexing), tight tolerances (±0.0005″), and surface integrity (no alpha case).

- Solutions:

- Use climb turning for thin walls to reduce flex.

- Apply HPC to prevent alpha case.

- Use CBN tools for finishing to meet tight tolerances.

2. Medical Implants

- Common Parts: Hip stems, knee implants (often CP Ti or Ti-6Al-4V ELI—extra low interstitial).

- Key Challenges: Biocompatibility (no toxic residues), smooth surface finish (Ra < 0.8 μm), and no microcracks.

- Solutions:

- Use PCD tools for finishing (they leave a smooth surface).

- Avoid oil-based coolants (they can leave residues)—use water-based synthetic coolants.

- Inspect the surface with a profilometer to ensure smoothness.

3. High-Performance Automotive

- Common Parts: Valve springs, connecting rods (often Ti-6Al-4V).

- Key Challenges: High production volumes, cost efficiency, and wear resistance.

- Solutions:

- Use coated carbide tools (affordable and long-lasting for high volumes).

- Optimize cycle time with trochoidal turning for deep cuts.

- Use chip breakers to keep production lines running smoothly (no chip tangles).

4. Cryogenic Applications

- Common Parts: Rocket fuel tanks, cryogenic valves (often Ti-3Al-2.5V).

- Key Challenges: Low-temperature toughness (no brittle fracture), and tight dimensional stability (titanium expands/contracts with temperature).

- Solutions:

- Machine at room temperature, then test parts at cryogenic temps (-196°C/-321°F).

- Use notch-insensitive tools to avoid microcracks.

- Maintain consistent coolant temperature to prevent dimensional variation.

Expert Case Study: Thin-Wall Turning for Aerospace

A client needed to turn a Ti-6Al-4V thin-wall cylinder (0.020″ wall thickness, 6″ length). Their first attempts failed: the wall flexed, causing poor roundness (out of tolerance by 0.002″). We adjusted their process:

- Switched to climb turning to reduce cutting forces.

- Used a short tool overhang (2x tool diameter) to minimize vibration.

- Reduced DOC to 0.015″ (from 0.025″) and increased feed rate to 0.004″ IPR.

- Added HPC (2,000 psi) to keep the wall cool.

The result? Roundness improved to ±0.0003″, and they met all aerospace specs.

Yigu Technology’s Perspective on Turning Titanium

Turning titanium demands a blend of material understanding, tooling expertise, and process precision—areas where Yigu Technology prioritizes innovation. We’ve observed that many manufacturers struggle with balancing efficiency and quality when machining titanium, often compromising on tool life or surface finish. Our view is that integrated solutions (not just individual tools or parameters) are the key: combining rigid machine setups, real-time monitoring, and application-specific tool geometries can transform titanium turning from a challenge to a competitive advantage. For example, we’ve supported aerospace clients by pairing our high-rigidity turning centers with AlTiN-coated carbide tools and trochoidal programming—cutting cycle times by 25% while improving tool life by 40%. We also emphasize sustainability: optimizing parameters to reduce scrap (a common issue with titanium) not only cuts costs but minimizes waste of this valuable material. Ultimately, turning titanium well isn’t just about technical skill—it’s about aligning every part of the process with the unique needs of the material and the application.

FAQ: Common Questions About Turning Titanium

1. What’s the best coolant for turning titanium?

Synthetic coolants with high thermal conductivity (and no chlorine or sulfur) are best. They resist reaction with titanium, cool the cutting edge effectively, and leave no toxic residues (critical for medical or food-grade parts). Avoid mineral-based coolants—they can form a sticky residue that causes galling.

2. How do I prevent work hardening when turning titanium?

Focus on three things: 1) Use a sharp cutting edge (dull edges rub, causing hardening). 2) Maintain a constant, moderate feed rate (too low = rubbing; too high = chipping). 3) Avoid dwell (don’t let the tool sit in one spot). If you notice work hardening (the tool starts to struggle), stop and adjust the feed rate or SFM.

3. Can I use the same tools for Ti-6Al-4V and pure titanium?

No—pure titanium (CP Ti) is softer and more ductile than Ti-6Al-4V, so it requires different tools. For pure titanium, PCD tools work well (they’re hard and low-friction). For Ti-6Al-4V (a tough alloy), coated carbide or CBN tools are better—they handle the higher cutting forces and heat.