In the field of mechanical transmission, transmission shafts are like the “spine” of equipment, responsible for transmitting power from the engine to wheels, aircraft propellers, and other key components. But have you ever thought about why some transmission shafts fail prematurely or can’t meet power transmission requirements? The root cause often lies in the quality of Transmission shaft CNC machining process design. A scientific and reasonable CNC machining process design is not only the guarantee of transmission shaft precision but also the key to improving its service life and reducing production costs.

1. Why Is Transmission Shaft CNC Machining Process Design Critical?

Transmission shafts work in complex environments, bearing torque and vibration for a long time. If the CNC machining process is not properly designed, it will bring a series of problems. Let’s first look at the consequences of improper process design and the benefits of excellent design through a comparison table:

| Aspect | Improper CNC Machining Process Design | Excellent CNC Machining Process Design |

| Dimensional Precision | Low (tolerance errors often exceed 0.05mm) | High (tolerance of Ф60 shaft section reaches level 6, Ф32 reaches level 7) |

| Service Life | Short (average failure time is 6 – 12 months) | Long (average service life is 2 – 3 years) |

| Production Cost | High (rework rate is over 20%, wasting materials and time) | Low (rework rate is less than 3%, reducing material waste) |

| Assembly Adaptability | Poor (difficult to match with other components, requiring manual adjustment) | Good (can be directly assembled with other components, no additional adjustment) |

Take an automobile manufacturing plant as an example. Previously, due to unreasonable CNC machining process design of transmission shafts, the coaxiality of the transmission shafts could not meet the requirements. During the test run, the transmission system made abnormal noises, and the failure rate of the transmission shafts reached 18%. After optimizing the process design (adjusting the sequence of turning, heat treatment, and finishing), the coaxiality error was controlled within the standard range, and the failure rate dropped to 2%.

2. Core Stages of Transmission Shaft CNC Machining Process Design

The CNC machining process design of transmission shafts is a linear and systematic project, which is divided into 8 key stages. Each stage is like a link in a chain, and only by ensuring the quality of each link can the final product meet the standards:

- Design Drawing Creation: First, use CAD software to draw detailed design drawings according to the application scenarios (such as automobiles, aircraft) and manufacturing standards of the transmission shaft. The drawing must include detailed dimensions (like the diameter and length of each shaft section), tolerance requirements, and surface roughness standards (such as Ra1.6 for key surfaces). This is like drawing a “blueprint” for the transmission shaft, which guides the subsequent processing.

- Material Preparation: Select appropriate materials based on the working load of the transmission shaft. Commonly used materials are carbon steel (for general load scenarios), alloy steel (for high – torque scenarios), and stainless steel (for corrosion – resistant scenarios). Then, cut, groove, and turn the material according to the length and diameter of the transmission shaft to make it into a blank that meets the initial processing requirements.

- Electrode Processing: Process electrodes on a CNC machine. Then, use electrical discharge machining and heating processes to shape the blank. This step can make the workpiece have the preliminary shape and size, and ensure the flatness and smoothness of the workpiece surface. It’s like “carving” the initial shape of the transmission shaft.

- Engraving and Etching: Use professional engraving and etching equipment to make necessary markings (such as part numbers, production dates), notches, and holes on the workpiece. These structures are crucial for the final assembly of the transmission shaft, as they can help workers accurately install the transmission shaft into the equipment.

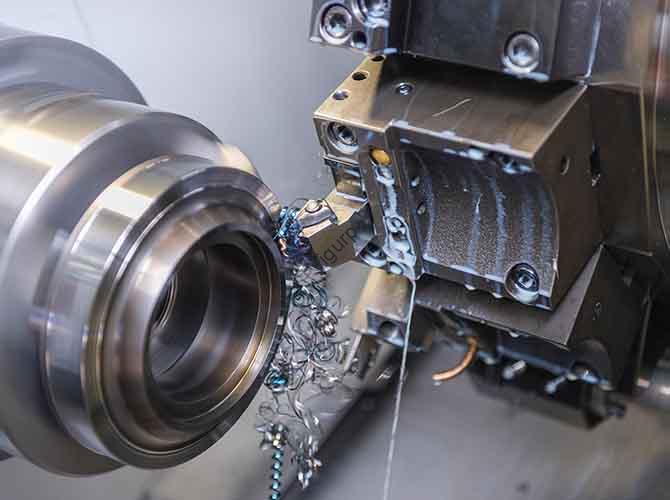

- CNC Turning and Punching: Use CNC lathes to perform turning operations on the workpiece, which can ensure the precision of the outer diameter and end face of the transmission shaft. At the same time, use CNC milling machines for punching to make holes of specific sizes and positions. This stage is the key to improving the dimensional precision of the transmission shaft.

- Heat Treatment: Before heat treatment, perform roughing on the workpiece (ordinary machine tools can be used for roughing). Then, carry out heat treatment processes such as quenching and tempering. Heat treatment can significantly improve the mechanical properties of the material, such as increasing the strength and hardness of the transmission shaft, making it more resistant to wear and torque.

- Finishing: This stage includes multiple processes. First, perform semi – finishing and finishing on the circular surface to make its size meet the design requirements. Then, perform rough turning and semi – finishing on the groove to ensure the accuracy of the groove size. Finally, perform rough milling, semi – finishing milling, and finishing on the U – groove. Finishing is like “polishing” the transmission shaft, which can further improve its precision and surface quality.

- Threading: Drill holes on the specified positions of the transmission shaft and tap M8 threaded holes. These threaded holes are used to connect the transmission shaft with other components (such as flanges), ensuring the stability of power transmission.

3. Key Factors to Consider in Transmission Shaft CNC Machining Process Design

When designing the CNC machining process of the transmission shaft, it is not enough to only follow the processing stages. We also need to focus on three key factors. If these factors are ignored, even if the processing steps are correct, the final product will not meet the requirements:

3.1 Tolerance Requirements

Different shaft sections of the transmission shaft have different tolerance requirements. For example, the Ф60 shaft section has a higher tolerance level, requiring level 6 tolerance (the allowable error is only a few thousandths of a millimeter), and the Ф32 shaft section requires level 7 tolerance. Why is the tolerance requirement so strict? Because if the tolerance exceeds the standard, the transmission shaft will have problems such as loose fit or tight fit when assembling with other components. A loose fit will cause power loss during transmission, and a tight fit will increase friction and accelerate wear.

3.2 Coaxiality Requirement

The coaxiality of the transmission shaft is a crucial indicator. The coaxiality tolerance of the axis line of the Ф60 shaft section relative to the axis line of the Ф32 shaft section must meet the design standard. Imagine the transmission shaft as a rotating “stick”. If the coaxiality is not good, the “stick” will swing during rotation, which will not only generate abnormal noise but also increase the load on the bearing, leading to premature failure of the bearing and the transmission shaft.

3.3 Surface Roughness

The surface roughness requirements of different machining surfaces of the transmission shaft are different. For example, the surface roughness of some key matching surfaces requires Ra1.6. A smooth surface (low roughness value) can reduce friction between the transmission shaft and other components, reduce wear, and also prevent the accumulation of dirt and impurities, improving the reliability of the transmission system. On the contrary, a rough surface will increase friction and may even cause scratches on the matching components.

4. Yigu Technology’s View on Transmission Shaft CNC Machining Process Design

At Yigu Technology, we hold that Transmission shaft CNC machining process design is the core to enhancing product competitiveness. Our R&D team integrates advanced CNC programming technology into the process design, optimizing the processing sequence of turning, heat treatment, and finishing. We’ve helped many clients cut production costs by 15% – 20% and extend transmission shaft service life by over 50%. In the future, we’ll keep exploring intelligent process design, combining AI to predict processing errors, and providing more efficient and precise solutions for clients.

5. FAQ: Common Questions About Transmission Shaft CNC Machining Process Design

Q1: What materials are suitable for transmission shafts in high – torque scenarios, and why?

A1: Alloy steel is suitable. Because alloy steel has higher strength and toughness compared with carbon steel. In high – torque scenarios, the transmission shaft bears a large rotational force, and alloy steel can resist deformation and fracture better, ensuring the stable transmission of power.

Q2: Can the order of heat treatment and finishing be reversed in the CNC machining process of transmission shafts?

A2: No. If finishing is done first and then heat treatment, the material will deform during heat treatment, which will destroy the precision of the finished surface. Therefore, it is necessary to perform roughing first, then heat treatment to improve the material properties, and finally finish to ensure the precision of the transmission shaft.

Q3: How to detect whether the coaxiality of the transmission shaft meets the requirements after machining?

A3: You can use a coaxiality detector. Install the transmission shaft on the detector, rotate the transmission shaft, and the detector will automatically measure the deviation of the axis line. If the deviation is within the design tolerance range, the coaxiality meets the requirements; otherwise, it needs to be reprocessed.