Tooling 3D Printing Services

Revolutionize your manufacturing workflow with Tooling 3D Printing—where additive manufacturing of tools meets precision, speed, and customization. At Yigu Technology, we turn tool design concepts into durable, high-performance assets, from custom jigs and fixtures to industrial-grade molds. Whether you’re a automotive manufacturer, electronics producer, or heavy machinery firm, our solutions deliver rapid prototyping for tooling, reduced production timelines, and enhanced tool performance that redefines efficiency in modern manufacturing.

Definition: What Is Tooling 3D Printing?

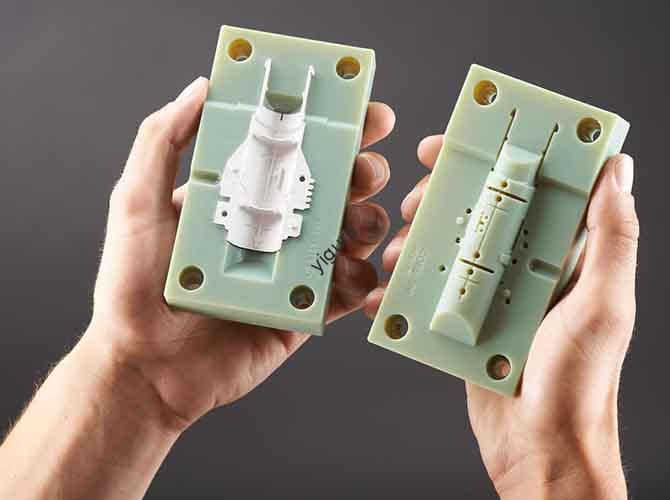

Tooling 3D Printing (also known as additive manufacturing of tools) is an innovative technology that builds industrial tools, fixtures, and molds layer by layer using specialized, high-strength materials. Unlike traditional tooling methods— which rely on time-consuming machining, casting, or forging—this process uses digital designs to create custom tool production that aligns with unique manufacturing needs.

At its core, Tooling 3D Printing is driven by digital fabrication of tooling—the use of 3D modeling software to craft every detail of a tool, from the texture of a mold cavity to the grip of a fixture. It enables rapid prototyping for tooling, letting manufacturers test tool designs in days instead of weeks, and eliminates the limitations of traditional tooling (e.g., fixed shapes, high upfront costs). From small-batch jigs to large-scale injection molds, this technology turns “one-size-fits-all” tooling into a thing of the past.

Our Capabilities: Crafting Tools That Drive Efficiency

At Yigu Technology, we’ve tailored our Tooling 3D Printing capabilities to meet the rigorous demands of industrial manufacturing. Our services balance precision, durability, and speed to deliver tools that enhance your production line.

| Capability | Key Features | Ideal Use Cases |

| High-Precision Printing | Layer resolution as low as 0.05mm; tight dimensional tolerance (±0.1mm) for critical tool features | Injection molds, precision jigs for electronics assembly, forming tools for small components |

| Custom Tool Designs | Fully personalized tool geometries (e.g., ergonomic grips, part-specific fixtures); collaborative design with engineering teams | Custom jigs for unique part shapes, brand-specific assembly tools, specialized molds |

| Durable and Strong Materials | Uses materials with high tensile strength (up to 800 MPa) and heat resistance (up to 300°C); tested for industrial wear | High-volume production molds, heavy-duty assembly tools, tools for high-temperature processes |

| Rapid Prototyping | Turnaround time as fast as 24 hours for simple tools; 3–5 days for complex molds; iterative design support | Tool concept testing, emergency replacement tools, pre-production tool validation |

| Quality Assurance | In-line dimensional scanning during printing; post-production stress testing; compliance with industry standards (ISO 9001, ASTM D638) | Aerospace tooling, medical device manufacturing tools, automotive critical-component fixtures |

Common Parts: Essential 3D-Printed Tools We Produce

Tooling 3D Printing serves nearly every manufacturing sector, with applications ranging from small assembly aids to large production molds. Below are the most common tools we create, along with real-world examples:

- Molds: We print molds for casting, thermoforming, and resin applications—from small plastic part molds to large composite molds. An automotive supplier used our 3D-printed thermoforming molds to produce interior trim pieces, cutting mold lead time by 60% compared to traditional steel molds.

- Jigs and Fixtures: Our 3D-printed jigs and fixtures (e.g., alignment jigs, holding fixtures) improve assembly accuracy and reduce worker fatigue. A electronics manufacturer implemented our custom PCB alignment jigs, reducing assembly errors by 45% and increasing production speed by 20%.

- Injection Molds: We print low-to-medium volume injection molds using high-strength polymers or metal composites. A consumer goods brand used our 3D-printed injection molds to produce 5,000 plastic bottle caps—avoiding the $50,000 cost of a traditional steel mold for a short production run.

- Forming Tools: We create forming tools for bending, stamping, or shaping materials (e.g., metal sheets, composites). A aerospace parts maker used our 3D-printed forming tools to shape lightweight aluminum components, achieving tighter tolerances than with traditional tools.

Assembly Tools: Our 3D-printed assembly tools (e.g., torque wrenches, part handlers) are tailored to specific production tasks. A heavy machinery firm used our custom part handlers to lift and position large components, reducing workplace injuries by 30% and cutting assembly time per unit by 15 minutes.

Process: From Design to Industrial-Grade Tool

Creating a 3D-printed tool is a structured, engineering-driven process that prioritizes performance, durability, and compatibility with your production line. At Yigu Technology, we streamline this process to minimize downtime and maximize tool value:

- Design and Modeling: We start by collaborating with your engineering team to understand tool requirements (e.g., load capacity, temperature exposure, production volume). Our team uses industrial 3D modeling software (e.g., SolidWorks, AutoCAD) to create a digital model, and we run simulations (e.g., stress tests, thermal analysis) to validate performance.

- Material Preparation: Based on the tool’s use case, we select and prepare the right material. For example, we melt and extrude carbon fiber reinforced materials for high-strength jigs, or sinter metal powders (aluminum, stainless steel) for heat-resistant molds. All materials are pre-tested for strength and durability.

- Printing and Layering: The 3D printer builds the tool layer by layer, using processes like FDM (Fused Deposition Modeling) for polymers or SLM (Selective Laser Melting) for metals. For complex tools (e.g., multi-cavity molds), the printer may print components separately for easier assembly later.

- Post-Processing (Finishing, Machining): After printing, we refine the tool through CNC machining (for tight tolerances), sandblasting (for surface texture), or heat treatment (to enhance material strength). For metal tools, we may add a protective coating to resist corrosion or wear.

Assembly and Integration: For multi-component tools (e.g., molds with inserts, jigs with fasteners), we assemble parts securely and test the tool’s fit with your existing production equipment. We also train your team on tool use and maintenance, if needed.

Materials: Industrial-Grade Choices for 3D-Printed Tools

The materials used in Tooling 3D Printing are carefully selected to meet the rigorous demands of manufacturing—from high load capacity to heat resistance. At Yigu Technology, we offer materials tailored to different tool types and applications:

| Material Type | Examples | Key Technical Benefits | Best For |

| Metals (Aluminum, Stainless Steel) | 6061 Aluminum, 316 Stainless Steel | High tensile strength (up to 550 MPa); heat resistance (up to 300°C); corrosion-resistant | High-volume molds, heavy-duty assembly tools, aerospace tooling |

| High-Strength Polymers | PA6 (Nylon), PEEK (Polyether Ether Ketone) | Excellent impact resistance; chemical resistance; low friction | Jigs and fixtures, low-volume injection molds, non-marring assembly tools |

| Composites | Carbon fiber-reinforced PA6, glass fiber-reinforced PEEK | Strength-to-weight ratio 3x higher than steel; lightweight; rigid | Aerospace forming tools, automotive jigs, portable assembly aids |

| Carbon Fiber Reinforced Materials | Carbon fiber-PLA, carbon fiber-ABS | High stiffness; dimensional stability; low thermal expansion | Precision jigs, alignment fixtures, lightweight molds |

| Tool-Grade Plastics | ABS-ESD (Anti-Static), PETG (Polyethylene Terephthalate Glycol) | ESD protection (critical for electronics); shatter-resistant; easy to machine | Electronics assembly jigs, static-sensitive part fixtures, prototype molds |

Data Insight: In 2024, 62% of our tooling clients chose composites for jigs and fixtures (due to their strength-to-weight ratio), while 75% of high-temperature tool projects (e.g., injection molds) used metals (for heat resistance and durability).

Advantages: Why Tooling 3D Printing Outperforms Traditional Methods

Tooling 3D Printing solves key pain points in traditional tooling—from long lead times to high costs—delivering tangible value to manufacturing operations:

- Customization: Every tool is tailored to your exact needs—whether it’s a fixture for a unique part shape or a mold with custom cavity designs. A medical device manufacturer used our custom 3D-printed molds to produce patient-specific components, a feat impossible with traditional one-size-fits-all tooling.

- Reduced Production Time: Traditional tooling can take 4–8 weeks to produce—3D printing cuts that to 3–7 days. An automotive parts supplier needed emergency replacement jigs for a broken production line; we delivered the 3D-printed jigs in 48 hours, minimizing downtime to just 6 hours (vs. 2 weeks for traditional jigs).

- Cost-Effective Prototyping: 3D printing eliminates the high upfront costs of traditional tooling (e.g., 10,000+forsteelmolds).Astartupmanufacturertested5differenttooldesignsusing3Dprintingforjust2,000 total—avoiding $50,000 in traditional prototyping costs.

- Enhanced Design Flexibility: 3D printing lets you integrate features that traditional tooling can’t—like internal cooling channels in molds (to reduce part cycle time) or ergonomic grips in jigs (to improve worker safety). A plastic injection molder added 3D-printed cooling channels to their molds, cutting part cooling time by 30% and increasing production output by 25%.

Improved Tool Performance: 3D-printed tools can outperform traditional ones in specific use cases. For example, our carbon fiber-reinforced jigs are 40% lighter than steel jigs (reducing worker fatigue) while maintaining the same load capacity—helping a heavy machinery firm increase worker productivity by 15%.

Case Studies: Success Stories in Tooling 3D Printing

Our work with manufacturers across industries has shown how 3D-printed tooling can transform efficiency, cost, and performance. Below are two standout projects:

Case Study 1: Automotive Supplier’s Injection Mold for Interior Trim

Client: AutoTrim Inc., a supplier of automotive interior components.

Goal: Produce 10,000 plastic interior trim pieces for a new car model—without the high cost of a traditional steel injection mold (which would take 6 weeks to deliver).

Solution: We designed and printed a high-strength injection mold using PEEK (a high-temperature polymer) reinforced with carbon fiber. The mold included integrated cooling channels to reduce part cycle time, and we used rapid prototyping to test and refine the mold design in 3 days.

Result: The 3D-printed mold produced 10,000 defect-free trim pieces in 4 weeks, at 70% lower cost than a traditional steel mold. AutoTrim Inc. also used the mold to test 2 design iterations before full production—something they couldn’t have done cost-effectively with traditional tooling.

Case Study 2: Electronics Manufacturer’s ESD-Safe Assembly Jigs

Client: TechCircuit Ltd., a producer of printed circuit boards (PCBs) for smartphones.

Goal: Replace their generic steel assembly jigs with ESD-safe (anti-static) jigs that align with their new PCB design—reducing assembly errors and protecting sensitive components from static damage.

Solution: We printed custom ESD-safe jigs using ABS-ESD (tool-grade plastic). The jigs included precision alignment pins (tolerance ±0.05mm) to ensure PCB components were placed correctly, and ergonomic handles to reduce worker fatigue. We delivered the first batch of 20 jigs in 5 days.

Result: TechCircuit Ltd. saw a 45% reduction in PCB assembly errors and a 20% increase in production speed. The ESD-safe material also eliminated static-related component damage, saving the company $30,000 in wasted parts annually. They later ordered 50 more jigs for their other production lines.

Why Choose Us: Yigu Technology’s Edge in Tooling 3D Printing

When it comes to Tooling 3D Printing, manufacturers choose Yigu Technology for our engineering expertise, industrial-grade quality, and focus on operational value. Here’s what sets us apart:

- Expertise in Tooling: Our team includes mechanical engineers with 10+ years of experience in manufacturing tooling. We understand the unique demands of different industries (e.g., aerospace, electronics, automotive) and design tools that integrate seamlessly with your existing workflow.

- Advanced 3D Printing Technology: We use industrial-grade 3D printers (from brands like Markforged, EOS, and Stratasys) optimized for tooling. Our printers support a wide range of materials—from polymers to metals—and offer precision controls to ensure consistent, high-quality results.

- High-Quality Materials: We source materials from trusted industrial suppliers and test every batch for strength, durability, and compliance with industry standards (e.g., ISO 9001, ASTM). All our materials are certified for use in manufacturing environments, including ESD-safe and food-grade options where needed.

- Comprehensive Support: We offer end-to-end support—from initial design consultation to post-delivery maintenance. Our team provides tool performance testing, training for your staff, and even repair services for 3D-printed tools, ensuring long-term value.

Competitive Pricing: We offer transparent pricing with no hidden costs. Our 3D-printed tools are 30–70% cheaper than traditional tooling for low-to-medium volume needs, and we provide flexible pricing for large orders or long-term partnerships.