Small batch production of carbon fiber product parts sits at the sweet spot between prototyping and mass manufacturing. It’s ideal for businesses launching new products, meeting niche market demands, or testing designs before scaling up. But to avoid wasted materials, delayed timelines, and inconsistent quality, you need a clear roadmap—one that ties together the right production techniques, materials, quality checks, and market insights. Below’s your go-to guide for seamless small batch carbon fiber part production.

1. Production Techniques: Choose the Right Method for Your Batch

Not all production techniques work for small batches. The best choice depends on your part’s shape, quantity, budget, and performance needs. Here’s a breakdown of the most effective options:

| Technique | Best For | Pros | Cons | Ideal Batch Size |

| Vacuum Bagging | Complex, low-volume parts (e.g., custom bike frames) | Low setup cost; works with woven fabrics | Slow (1-2 parts/day); labor-intensive | 5-20 parts |

| Compression Molding | Uniform, high-strength parts (e.g., automotive brackets) | Fast cycle time (15-30 mins/part); consistent quality | High mold cost; limited to simple shapes | 20-50 parts |

| Resin Transfer Molding (RTM) | Detailed parts with tight tolerances (e.g., electronics enclosures) | Minimal waste; good surface finish | Longer setup; needs precise resin control | 10-30 parts |

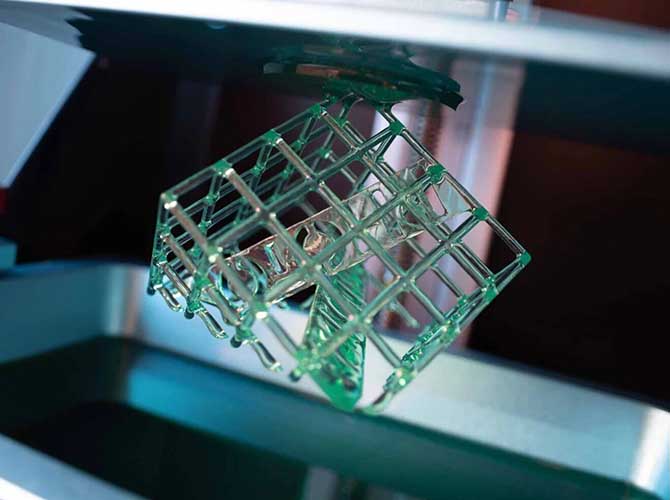

| 3D Printing / Additive Manufacturing | Intricate, one-off parts (e.g., medical device prototypes) | No mold needed; design flexibility | Slow for large parts; lower strength vs. molded parts | 1-10 parts |

| Autoclave Processing | High-performance parts (e.g., aerospace components) | Eliminates voids; maximum strength | High equipment cost; long cure times | 5-15 parts |

| Injection Molding | Small, high-volume small batches (e.g., consumer electronics parts) | Fast (1-2 mins/part); high repeatability | Very high mold cost; resin limits | 50-100 parts |

Pro Tip: For batches under 20 parts, Vacuum Bagging or 3D Printing is often most cost-effective. For 20-50 parts, Compression Molding strikes a balance between speed and cost.

2. Material Selection: Match Materials to Performance Goals

Carbon fiber parts are only as good as their materials. For small batches, you need materials that are easy to work with, consistent, and aligned with your part’s end use. Here’s how to choose:

Core Material Categories & Uses

| Category | Key Options | Best For |

| Carbon Fiber Reinforcement | Unidirectional Fibers (strength in one direction); Woven Fabrics (balanced strength) | Unidirectional: Automotive drive shafts; Woven: Sports equipment (e.g., tennis rackets) |

| Resins | Epoxy Resin (strong, heat-resistant); Thermoplastic Resins (recyclable, fast-curing); Thermosetting Resins (durable, high-temperature tolerance) | Epoxy: Aerospace parts; Thermoplastic: Consumer electronics; Thermosetting: Industrial tools |

| Prepregs | Fiber-resin composites (ready to mold) | Parts needing consistent quality (e.g., medical devices) |

| Additives | Fillers (reduce cost; improve stiffness); Adhesives (bond parts) | Fillers: Low-load parts (e.g., decorative trims); Adhesives: Assembled parts (e.g., drone bodies) |

Question: When should I use thermoplastic vs. thermosetting resin for small batches?

Answer: Choose thermoplastic if you need fast curing (great for tight timelines) or recyclable parts. Pick thermosetting if your part needs to handle high heat or heavy loads (e.g., engine components).

3. Quality Control: Ensure Consistency in Every Batch

Small batches leave little room for error—one defective part can derail your project. A strict quality control (QC) process keeps standards high without slowing production.

Step-by-Step QC Checklist

- Pre-Production Check: Verify material consistency (e.g., prepreg expiration dates, fiber alignment). Reject any materials with visible flaws (e.g., torn fabric, lumpy resin).

- In-Process Inspection:

- Monitor curing parameters (temperature, time) with digital sensors—deviations of ±5°C can weaken parts.

- Check lamination for air bubbles (use a flashlight to spot voids).

- Post-Production Testing:

- Visual Inspection: Look for surface defects (scratches, uneven finish). Use a checklist to ensure consistency.

- Non-Destructive Testing (NDT): Use Ultrasonic Testing to find internal flaws (e.g., delamination) or X-ray Imaging for critical parts (e.g., aerospace components).

- Mechanical Testing: Measure Tensile Strength (per ASTM D3039) and Flexural Strength (per ASTM D790) on 10% of each batch.

- Dimensional Accuracy: Use a 3D scanner to compare parts to CAD models—aim for ±0.1mm tolerance for precision parts.

Key Quality Standards to Follow

- ISO 1463: For carbon fiber composites

- ASTM D3039: For tensile testing

- AMS 3859: For aerospace-grade parts

Example: A sports equipment maker producing small-batch carbon fiber bike forks uses ultrasonic testing on every fork. This caught a tiny internal void in 1 out of 15 forks—preventing a potential safety hazard and costly recalls.

4. Market and Application: Align Production with Demand

Small batch production thrives when it’s tied to clear market needs. Understanding your target market and application requirements ensures your parts sell (or perform) as intended.

Target Markets & Their Needs

| Market | Application Examples | Key Production Requirements |

| Automotive Industry | Lightweight body panels, interior trims | Fast production; low cost; impact resistance |

| Aerospace Industry | Satellite components, aircraft brackets | High strength-to-weight ratio; compliance with AMS standards; zero defects |

| Sports Equipment | Golf club shafts, bicycle frames | Customization; stiffness; aesthetic appeal (smooth surface finish) |

| Consumer Electronics | Phone cases, laptop stands | Thin walls; precise dimensions; heat resistance |

| Medical Devices | Prosthetic parts, surgical tools | Biocompatible materials; tight tolerances (±0.05mm); traceable batches |

| Niche Markets | Drone frames, racing parts | Rapid turnaround; custom designs; small batch flexibility |

Competitive Edge for Small Batches

Small batch producers can outperform mass manufacturers by:

- Offering custom products (e.g., personalized sports gear).

- Delivering faster (4-6 weeks vs. 12+ weeks for mass production).

- Focusing on high-margin niche markets (e.g., luxury automotive parts) where big brands can’t compete.

Yigu Technology’s Perspective

For small-batch carbon fiber parts, prioritize flexibility and quality over scale. We recommend pairing Vacuum Bagging (for complex shapes) or Compression Molding (for consistency) with epoxy prepregs—balances cost and performance. Use NDT (ultrasonic testing) on 100% of critical parts (aerospace/medical) to avoid risks. Align production with niche demands (e.g., custom drone parts) to stand out. Our clients cut small-batch defects by 30% using this approach.

FAQ

- What’s the cheapest production technique for small-batch carbon fiber parts?

Vacuum Bagging—setup costs are low (under $500 for basic equipment), and it works with affordable woven fabrics. It’s best for batches of 5-20 parts.

- Do I need to test every part in a small batch?

No—test 10% for mechanical strength (e.g., tensile testing) and do visual inspections on all parts. For critical parts (e.g., medical devices), use NDT on 100%.

- Which market is easiest to enter with small-batch carbon fiber parts?

Sports equipment (e.g., custom bike frames). Niche buyers value customization, and production needs (flexible shapes, moderate strength) fit small-batch techniques like Vacuum Bagging.