When developing new products—whether in aerospace, automotive, or electronics—the CNC machining prototype shell plays a critical role. It’s not just a simple outer cover; it’s a testbed for design feasibility, performance, and production scalability. This guide breaks down everything you need to know about prototype shells, from material choices to real-world applications, helping you avoid common pitfalls and create high-quality prototypes.

1. What Is a CNC Machining Prototype Shell?

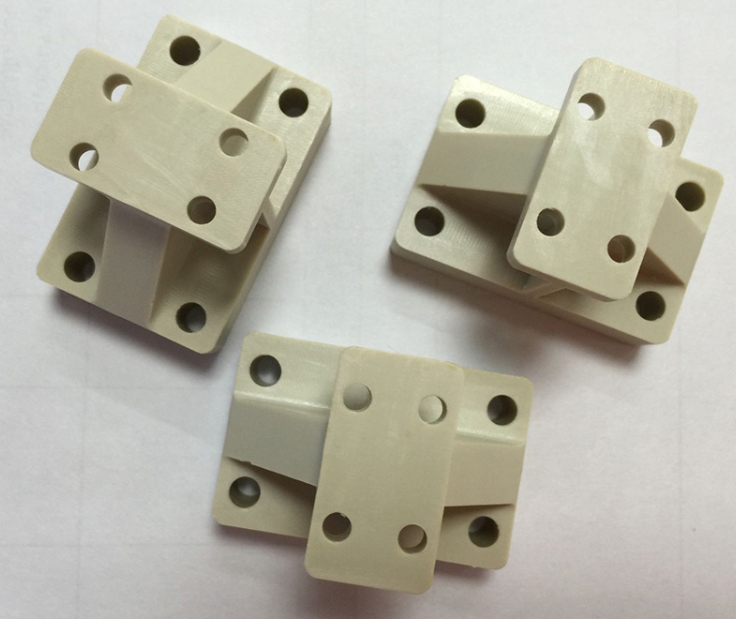

A CNC machining prototype shell is a custom-designed outer component produced via Computer Numerical Control (CNC) technology to test a product’s form, fit, and function before mass production. Unlike 3D-printed prototypes (which are often for quick visual checks), CNC-machined prototype shells use the same materials as final products (e.g., aluminum alloy, stainless steel) and match the precision of mass-produced parts—typically ±0.005mm tolerance.

Key Purpose of Prototype Shells:

- Verify if the shell fits internal components (e.g., circuit boards in electronic devices).

- Test durability under real-world conditions (e.g., corrosion resistance for automotive parts).

- Validate manufacturing processes (e.g., can the design be scaled without deformation?).

2. Top Materials for CNC Machining Prototype Shells

Choosing the right material directly impacts your prototype’s performance and cost. Aluminum alloy is the most popular choice, but other materials suit specific needs. Below is a comparison of common options:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Cost (USD/kg) | Best For |

| Aluminum Alloy 6061 | 2.70 | 310 | Excellent | \(2.5–\)4.0 | Electronic device shells, automotive parts |

| Stainless Steel 304 | 7.93 | 515 | Superior | \(3.8–\)6.5 | Medical equipment, marine components |

| Titanium Alloy Ti-6Al-4V | 4.43 | 860 | Exceptional | \(35–\)50 | Aerospace prototype shells |

Real-World Example: A leading smartphone manufacturer used aluminum alloy 6061 for its CNC machining prototype shell. The material’s lightweight (2.7g/cm³) and good machinability allowed the team to test 3 different shell thicknesses (1.2mm, 1.5mm, 1.8mm) in 2 weeks—faster than using stainless steel and cheaper than titanium.

3. Step-by-Step Process for CNC Machining Prototype Shells

Creating a prototype shell requires careful planning to ensure accuracy and efficiency. Below is a 7-step workflow used by top manufacturers:

- Design & 3D Modeling: Use CAD software (e.g., SolidWorks, AutoCAD) to create a detailed 3D model of the shell. Define critical features like holes, grooves, and wall thicknesses. For example, a drone prototype shell needs precise mounting points for propellers—these are marked in the CAD model.

- Material Preparation: Cut the raw material (e.g., aluminum alloy sheet) into a “blank” slightly larger than the final shell (usually +5mm on all sides) to account for machining.

- Cutting Parameter Setup: Select CNC tools (e.g., end mills, drills) and set parameters like spindle speed (10,000–15,000 RPM for aluminum) and feed rate (500–1,000 mm/min) to avoid vibration.

- Fixture Installation: Secure the blank to the CNC machine with a rigid fixture (e.g., vice clamps) to prevent deformation during cutting. A loose fixture can cause up to 0.1mm of error—enough to ruin a prototype.

- CNC Machining: The machine follows the CAD model’s path to cut the shell. For complex shapes (e.g., curved automotive sensor shells), 5-axis CNC machines are used to access hard-to-reach areas.

- Post-Processing: Clean the shell to remove metal shavings, then add surface treatments:

- Sandblasting: For a matte finish (common in industrial prototypes).

- Anodizing: To improve corrosion resistance (used for aluminum shells in outdoor devices).

- Polishing: For a smooth, consumer-friendly look (e.g., smartphone prototype shells).

- Inspection & Testing: Use tools like calipers and coordinate measuring machines (CMMs) to check dimensions. Then test the shell—for example, an electronic device shell might undergo drop tests (1.5m height onto concrete) to check durability.

4. Advanced Technologies Boosting Prototype Shell Quality

To meet growing demands for faster, more precise prototypes, manufacturers are adopting these advanced CNC technologies:

- High-Speed Cutting (HSC): Uses spindle speeds over 20,000 RPM to reduce machining time by 30–50%. A medical device company cut the time to make a stainless steel prototype shell from 8 hours to 4.5 hours using HSC.

- Adaptive Machining: Adjusts cutting parameters in real time to account for material inconsistencies. This is critical for titanium prototype shells, where small material defects can cause tool breakage.

- Digital Twin Simulation: Creates a virtual copy of the machining process to predict issues (e.g., vibration, overheating) before physical production. One aerospace firm used this to fix a shell deformation problem that had delayed its prototype by 2 weeks.

5. Yigu Technology’s Perspective on CNC Machining Prototype Shells

At Yigu Technology, we believe the CNC machining prototype shell is the bridge between design and mass production. Over the past 5 years, we’ve supported 200+ clients—from startups to Fortune 500 companies—in developing prototype shells. Our team prioritizes material matching (using the same alloy as final products) and rapid iteration (delivering most aluminum prototype shells in 3–5 days). We’ve found that investing in high-precision prototype shells reduces mass production errors by 40% on average, saving clients time and cost. For small-batch or custom projects, our flexible manufacturing setup ensures even complex shell designs (e.g., 3D curved automotive shells) meet strict tolerance requirements.

FAQ About CNC Machining Prototype Shells

Q1: How long does it take to make a CNC machining prototype shell?

A: It depends on material and complexity. For simple aluminum shells (e.g., a small electronic enclosure), it takes 3–5 days. For complex titanium aerospace shells, it may take 1–2 weeks.

Q2: Can CNC machining prototype shells be used for small-batch production?

A: Yes! Unlike 3D printing (which is slow for small batches), CNC-machined prototype shells can be scaled to 50–100 units without retooling. This is ideal for pre-launch product testing with real users.

Q3: How much does a CNC machining prototype shell cost?

A: Costs vary by material and size. A small aluminum alloy shell (100x100x50mm) typically costs \(50–\)150. A large titanium aerospace shell (300x200x100mm) can cost \(500–\)1,200.