If you’re searching for “Sheet Metal Portugal,” you’re likely looking to partner with a reliable sheet metal manufacturer, source high-quality components, or understand the country’s role in Europe’s metalworking sector. The good news is that Portugal’s sheet metal industry stands out for its combination of technical expertise, competitive pricing, and adherence to EU quality standards—making it a top choice for businesses across automotive, aerospace, and industrial sectors. In this guide, we’ll break down everything you need to know, from the industry’s core strengths to how to choose the right partner, and even future trends shaping its growth.

1. The State of the Sheet Metal Industry in Portugal: Key Facts and Figures

Portugal’s sheet metal sector is a vital part of its manufacturing economy, contributing significantly to exports and employment. To understand its value, let’s start with hard data and core strengths that set it apart.

Core Industry Strengths

- EU Compliance: All Portuguese sheet metal manufacturers follow strict EU regulations, including REACH (for chemical safety) and CE marking (for product safety). This eliminates compliance risks for businesses selling in Europe.

- Skilled Workforce: Portugal invests in vocational training programs for metalworkers, with institutions like the Instituto de Formação Profissional e Emprego (IFPE) providing specialized courses in sheet metal fabrication, welding, and CNC operation.

- Export-Focused: Over 60% of Portugal’s sheet metal output is exported, primarily to other EU countries (Spain, France, Germany) and global markets like the US and Brazil. This means manufacturers are experienced in international logistics and customer needs.

Key Statistics (2024 Estimates)

| Metric | Value | Source |

| Number of sheet metal manufacturers | 800+ | Associação Portuguesa da Indústria Metalúrgica, Mecânica e de Materiais (APIMEC) |

| Industry turnover | €2.3 billion | APIMEC Annual Report 2023 |

| Employment in the sector | 28,000+ workers | Portuguese Ministry of Economy |

| Top export market | Spain (32% of exports) | Eurostat |

Real-World Example: A Success Story

Take Metalúrgica Fernandes, a family-owned sheet metal company based in Porto. Founded in 1985, it started as a small workshop but now supplies sheet metal components to major automotive brands like Volkswagen and Renault. Their success lies in combining traditional craftsmanship with modern CNC technology—allowing them to produce complex parts with tight tolerances (as low as ±0.1mm). This example shows how Portuguese sheet metal firms scale while maintaining quality, a common trait in the industry.

2. Why Choose Sheet Metal Manufacturers in Portugal?

You might wonder: with other European countries (like Germany or Italy) known for manufacturing, why pick Portugal? The answer lies in a unique balance of quality, cost, and flexibility that meets the needs of small-to-medium businesses (SMBs) and large corporations alike.

Cost Competitiveness Without Sacrificing Quality

Portugal offers lower labor and operational costs compared to Western European nations like Germany or Sweden—typically 15-25% lower for equivalent sheet metal services. This doesn’t mean cutting corners: most manufacturers use state-of-the-art equipment (e.g., fiber laser cutters, robotic welding arms) to ensure precision. For example, a German company sourcing a batch of sheet metal brackets might pay €12 per unit from a local supplier, but €9 per unit from a Portuguese manufacturer—with the same ISO 9001 certification.

Flexibility for Small and Large Orders

Unlike some large manufacturers that require minimum order quantities (MOQs) of 1,000+ units, many Portuguese sheet metal firms cater to smaller orders (starting from 50 units). This is ideal for startups or businesses testing new products. For instance, SheetMetalLisbon, a manufacturer in the capital, specializes in prototype and low-volume production—helping a UK-based startup create 100 custom sheet metal enclosures for their new IoT device in just 2 weeks.

Proximity to Major European Markets

Portugal’s location (on Europe’s southwest coast) means fast shipping to key markets. For example:

- Shipping to Madrid (Spain) takes 1-2 days by road.

- Shipping to Paris (France) takes 3-4 days by road or rail.

- Air freight to Berlin (Germany) takes 24 hours.

This reduces lead times and logistics costs, a critical factor for businesses with tight production schedules.

3. Key Sheet Metal Processes and Capabilities in Portugal

Portuguese manufacturers offer a full range of sheet metal services, from design to finishing. Understanding these capabilities will help you find a partner that matches your project needs.

Common Sheet Metal Processes

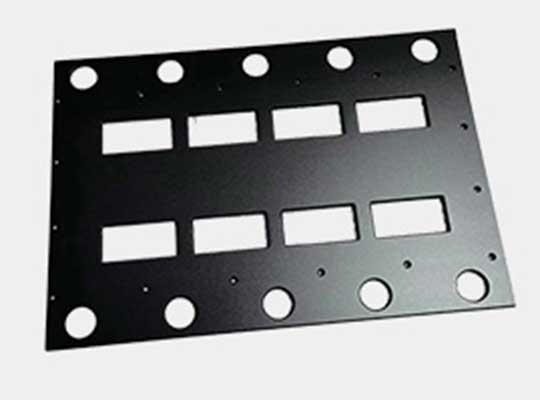

- Laser Cutting: Most firms use fiber laser cutters, which can cut metals like steel, aluminum, and stainless steel up to 25mm thick with high precision. This is ideal for complex shapes (e.g., automotive parts, electrical enclosures).

- CNC Punching: Used for high-volume production of holes, notches, or simple shapes. It’s faster and more cost-effective than laser cutting for repetitive designs.

- Bending and Forming: Using CNC press brakes, manufacturers can bend sheet metal into angles (90°, 135°, etc.) or 3D shapes. The maximum bending length typically ranges from 1.5m to 3m, depending on the machine.

- Welding: Common methods include MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding. Robotic welding is increasingly used for consistency, especially in automotive and aerospace projects.

- Finishing: Services like powder coating (available in 100+ colors), galvanizing (for corrosion resistance), and silk-screening (for branding) are widely offered.

Specialized Capabilities for Niche Sectors

Some manufacturers focus on niche industries, offering specialized services:

- Aerospace: Manufacturers like Aernnova Portugal (based in Viseu) produce sheet metal components for aircraft, complying with strict AS9100 standards (aerospace quality management).

- Medical Devices: Firms like Metalúrgica Gomes create sheet metal parts for medical equipment (e.g., hospital beds, diagnostic machines) with biocompatible finishes.

- Renewable Energy: With Portugal’s push for wind and solar power, companies like EnergiMetal make sheet metal structures for wind turbines and solar panels, designed to withstand harsh weather conditions.

4. How to Choose the Right Sheet Metal Partner in Portugal

Selecting a manufacturer that aligns with your project goals is crucial. Follow these steps to make an informed decision.

Step 1: Define Your Project Requirements

Before reaching out to suppliers, clarify:

- Material type (e.g., mild steel, aluminum, stainless steel) and thickness.

- Required processes (e.g., laser cutting, bending, welding).

- Order volume (prototype, low-volume, high-volume).

- Quality standards (e.g., ISO 9001, AS9100, IATF 16949 for automotive).

- Lead time (how quickly you need the parts).

Step 2: Verify Certifications and Quality Control

Always check for relevant certifications. The most important ones for sheet metal in Portugal are:

- ISO 9001: Ensures consistent quality management.

- IATF 16949: For automotive-specific manufacturing (required by brands like Ford or Toyota).

- AS9100: For aerospace components.

Ask the manufacturer to share their quality control (QC) process—for example, do they inspect parts at every stage (cutting, bending, welding) or only at the end? A reliable partner will have a documented QC plan.

Step 3: Evaluate Experience and References

Look for a manufacturer with experience in your industry. For example, if you need sheet metal parts for a food processing machine, choose a firm that has worked with food industry clients (they’ll understand requirements like stainless steel grades and easy-to-clean designs).

Ask for references or case studies. A good supplier will be happy to share contact details of past clients. Reach out to these clients and ask:

- Did the manufacturer meet deadlines?

- Were the parts of consistent quality?

- How did they handle issues (e.g., incorrect dimensions)?

Step 4: Compare Quotes and Lead Times

Get quotes from 2-3 manufacturers. Don’t just choose the cheapest option—consider factors like quality, experience, and lead time. For example, a slightly higher quote from a manufacturer with faster lead times might be worth it if you need parts urgently.

Make sure the quote includes all costs (e.g., material, labor, finishing, shipping) to avoid hidden fees later.

5. Future Trends Shaping Portugal’s Sheet Metal Industry

To stay ahead, it’s important to understand the trends driving the industry. Here are the key developments to watch:

1. Automation and Industry 4.0

More Portuguese sheet metal manufacturers are adopting automation and Industry 4.0 technologies. This includes:

- Robotic Arms: Used for welding, material handling, and assembly—reducing human error and increasing production speed.

- Digital Twin Technology: Creating a virtual copy of the production process to test designs and optimize efficiency before physical production.

- IoT Sensors: Installed on machines to monitor performance and predict maintenance needs (e.g., a sensor on a laser cutter might alert the team when a part needs replacement, preventing unexpected downtime).

For example, MetalTech Porto recently invested €500,000 in robotic welding arms, cutting production time for automotive parts by 30% while improving weld quality.

2. Sustainability and Green Manufacturing

Portugal is committed to reducing carbon emissions, and the sheet metal industry is following suit. Key sustainable practices include:

- Recycled Materials: Using recycled steel and aluminum (recycled aluminum uses 95% less energy to produce than virgin aluminum).

- Energy-Efficient Machines: New laser cutters and press brakes are designed to use less electricity.

- Waste Reduction: Optimizing nesting (the process of arranging parts on a sheet of metal) to minimize scrap. Some manufacturers now achieve scrap rates as low as 5% (down from 10-15% a decade ago).

- Eco-Friendly Finishes: Using powder coatings with low VOC (volatile organic compound) emissions.

Many manufacturers are also seeking ISO 14001 certification (environmental management), which demonstrates their commitment to sustainability.

3. Growth in Renewable Energy and Electric Vehicles (EVs)

Portugal’s focus on renewable energy (it aims to be carbon-neutral by 2050) and the global shift to EVs are creating new opportunities for the sheet metal industry. Demand is rising for:

- Sheet metal structures for wind turbines (e.g., tower sections, nacelle enclosures).

- Components for solar panels (e.g., frames, mounting systems).

- EV parts (e.g., battery enclosures, chassis components).

APIMEC predicts that the renewable energy and EV sectors will drive a 12% growth in sheet metal demand in Portugal by 2026.

6. Yigu Technology’s Perspective on Sheet Metal Portugal

Yigu Technology recognizes Portugal as a standout player in Europe’s sheet metal landscape, thanks to its unique blend of quality, cost-effectiveness, and adaptability. What sets Portugal apart is its ability to serve both small businesses and large enterprises—offering low MOQs for startups while having the scale to meet the needs of automotive or aerospace giants. The industry’s focus on sustainability and Industry 4.0 also aligns with global manufacturing trends, making it a forward-thinking partner for businesses aiming to reduce their carbon footprint and improve efficiency. For companies looking to source sheet metal in Europe, Portugal isn’t just a cost-saving option—it’s a strategic choice that balances reliability, expertise, and future readiness.

FAQ: Common Questions About Sheet Metal Portugal

1. What types of metals do Portuguese sheet metal manufacturers work with?

Most manufacturers handle a range of metals, including mild steel (the most common), aluminum (lightweight and corrosion-resistant), stainless steel (ideal for food, medical, or outdoor applications), and copper (used in electrical components). Some also work with specialty metals like titanium for aerospace projects.

2. How long does it take to get sheet metal parts from Portugal?

Lead times depend on order volume and complexity. For prototypes or small orders (50-100 units), you can expect 1-2 weeks. For high-volume orders (1,000+ units), lead times are typically 3-4 weeks. Shipping to other EU countries adds 1-4 days, depending on the destination.

3. Do Portuguese manufacturers offer design support?

Yes, many provide design for manufacturing (DFM) support. Their engineers can review your 3D models or drawings to suggest improvements that reduce costs or improve production efficiency (e.g., changing a complex shape to make it easier to laser cut).

4. Are Portuguese sheet metal parts compliant with EU regulations?

Absolutely. All reputable manufacturers follow EU standards, including CE marking (for product safety), REACH (for chemical restrictions), and specific industry standards like IATF 16949 (automotive) or AS9100 (aerospace). They can provide documentation to prove compliance.

5. Can I visit a Portuguese sheet metal factory before placing an order?

Most manufacturers welcome factory visits, especially for large or long-term projects. This allows you to see their equipment, quality control processes, and working conditions firsthand. Many also offer virtual tours if you can’t travel in person.